Nano molybdenum disulfide

Particle size: 200nm

Purity: 99.9%

Specific surface area (m2/g): 13

Bulk density (g/cm3): 1.2

Density (g/cm3): 5

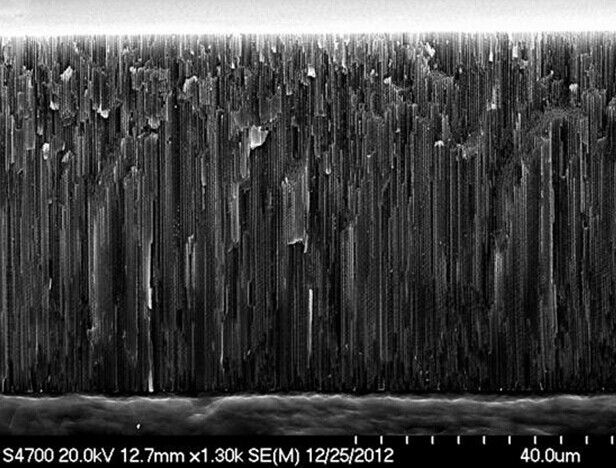

Crystal form: flake

Colour: Black

Product performance

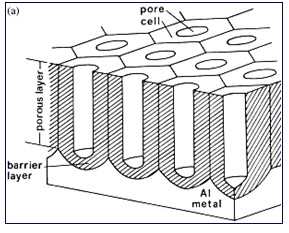

As a commonly used solid lubricant, nano-molybdenum disulfide has a layered structure, and the sulfur-bonding force between the layers is weak and easy to slide, which shows a good anti-friction effect; on the other hand, exposure The sulfur atom on the surface of the crystal has a strong adhesion to the metal surface, forming a very strong film, and the lubricating performance is superior to other general lubricating materials. Compared with ordinary molybdenum disulfide, nano molybdenum disulfide has many excellent properties, such as : Excellent friction, large specific surface area, strong adsorption capacity, high reactivity, catalytic performance, especially catalytic hydrogenation desulfurization, can be used to prepare special catalytic materials and gas storage materials. The nano-intercalation composite formed by inserting other groups between the nano-molybdenum disulfide layers has many excellent physical properties (such as light, electricity, magnetism, catalysis, lubrication, etc.). As the particle size of MoS2 becomes smaller, its adhesion and coverage on the surface of the friction material are significantly improved, and the antiwear and antifriction properties are also significantly improved.

Application direction

1. Application in lubricants: not only can increase the maximum no-biting load of lubricating oil, but also reduce wear and improve the friction performance of materials. The mechanism is that nano-molybdenum disulfide is more susceptible to tribochemical than ordinary molybdenum disulfide. The reaction forms a lubricating film rich in sulfur and molybdenum, and the anti-wear effect, the mechanism of molybdenum disulfide reducing friction and wear is completely different from that of grease, and can maintain its excellent anti-friction and wear properties under high vacuum, mainly Used in equipment that is not easy to maintain, such as spacecraft, satellite and military.

2. Application in composite materials: PS/MoS2 nanocomposites, using MoS2 with certain conductivity as conductive filler to improve the electrical properties of polystyrene (PS), so that it has certain antistatic ability but not to Change its insulation.

Compared with the general molybdenum disulfide, the surface atom number of nanometer molybdenum disulfide is significantly increased, forming more sulfur vacancies, making it more catalytic activity and selectivity, and can be used as a high activity hydrogenation catalyst for heavy oil conversion and fuel refining. Nano MoS2 is used as a catalyst in the methanation of carbon monoxide, and has high selectivity and reactivity. Nano-molybdenum disulfide is a catalyst for coal liquefaction

Contact us:

If you have any question, please contact us.

Email:mxenes@163.com

Tel/Wechat:+86-18101240246( technician )17611215338(salesman)

QQ:2820939878

Skype: simon541142052

Whasapp: +86 18101263250

|

Warm tip: the products supplied by Beijing Beike Xincai Technology Co., Ltd. are only used for scientific research, not for human body |