1. Nano porous toner

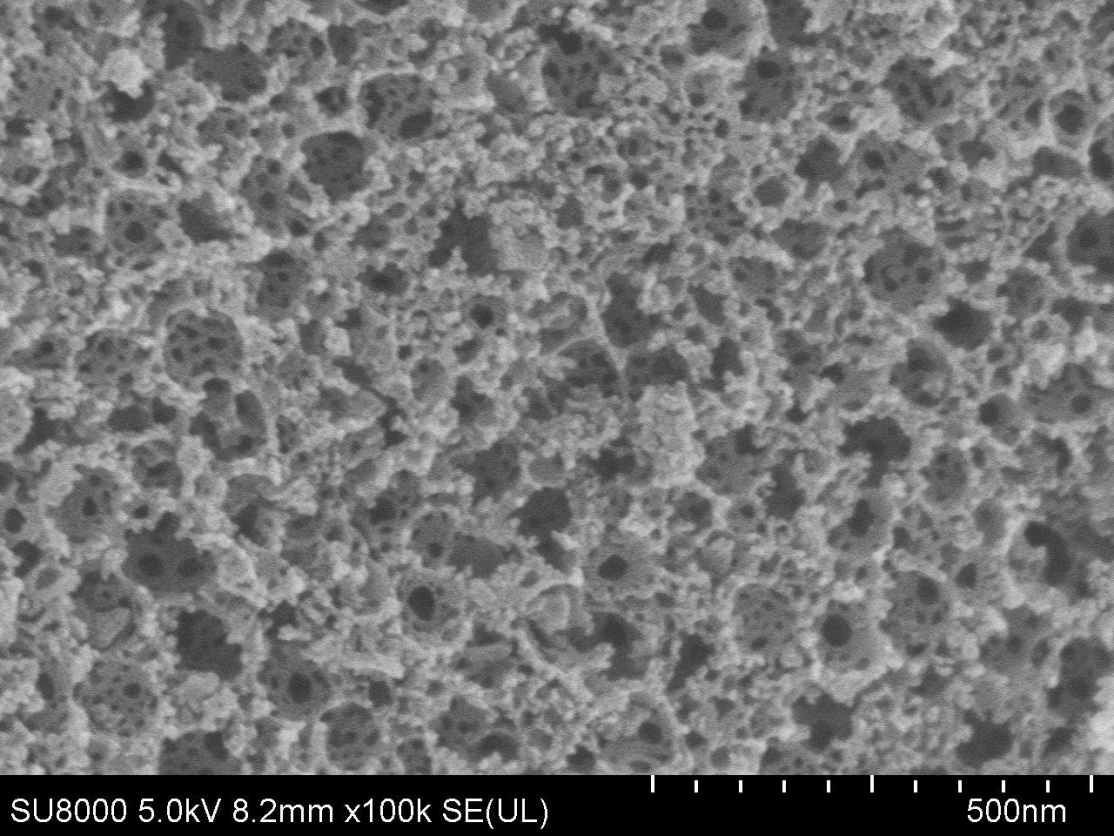

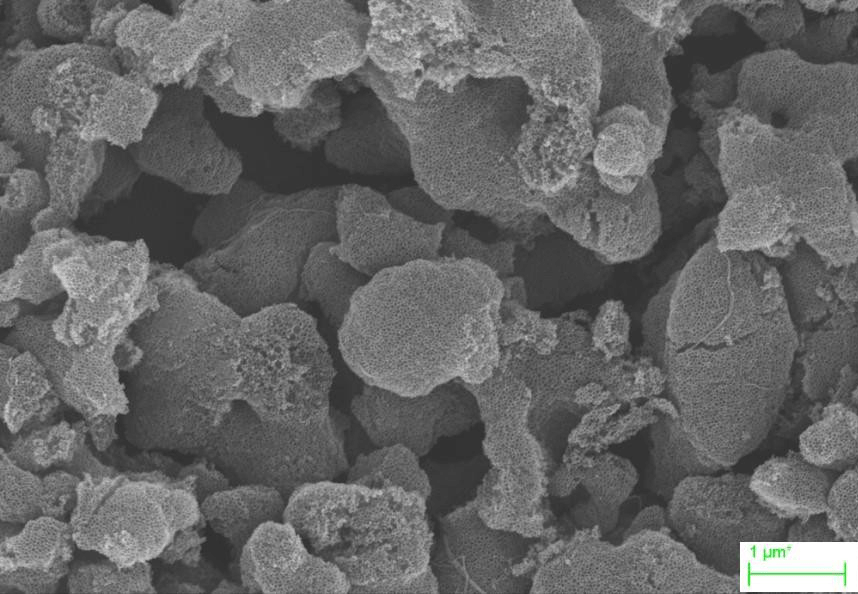

Nanoporous Carbon Powders (NCP).

Composition: The basic components are carbon 91-95%, oxygen 4-8%, hydrogen 1%, with good electrical conductivity (2-10 S/cm) and excellent chemical stability. If necessary, the carbon content can be further increased, up to more than 99%, and the conductivity will be improved simultaneously.

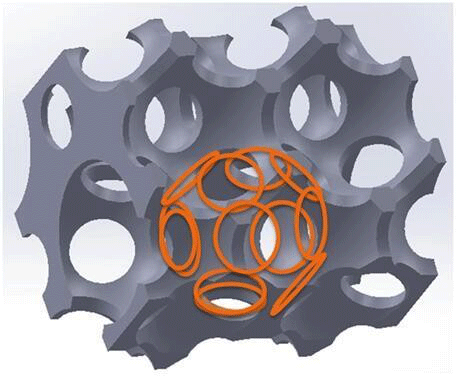

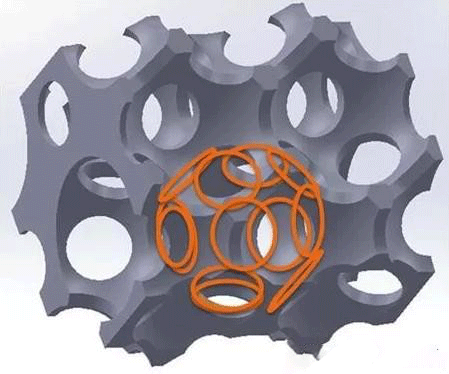

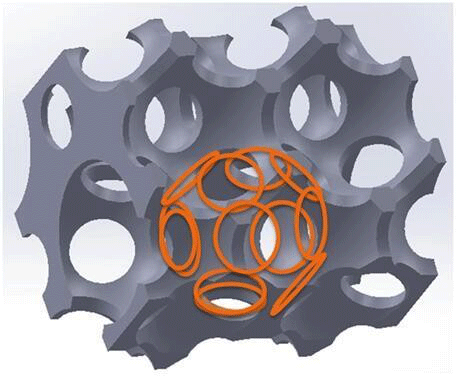

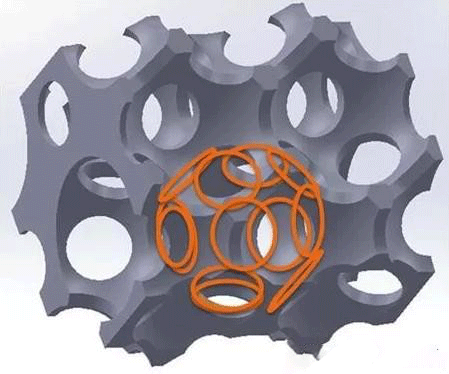

Structure: The inside is a three-dimensional nanoporous structure, each hole is in phase with the surrounding 12 holes

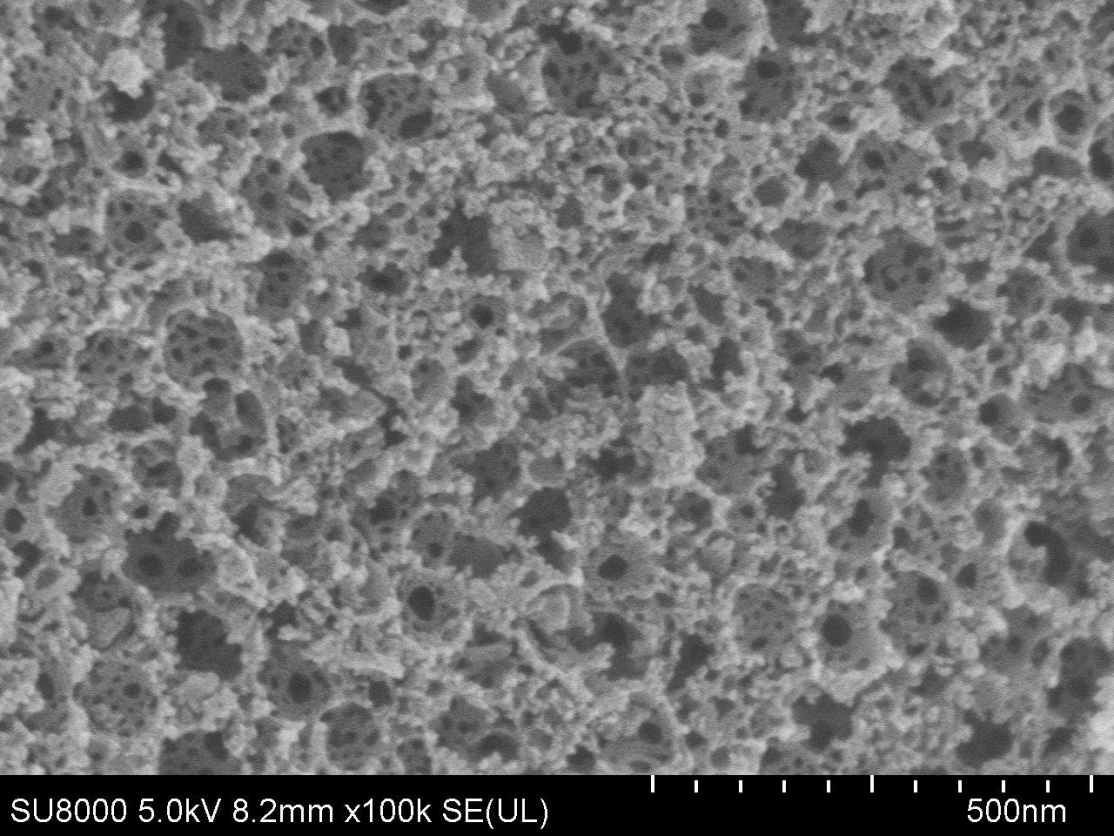

Even, the pores present the characteristics of large belly and small mouth, the pore structure is orderly, and the pore size distribution is narrow, which can be precisely adjusted in the range of 10-1000 nanometers. A large number of micropores are also distributed on the surface of the hole wall, which is conducive to trapping metal ions.

Surface characteristics: The surface of the inner wall of the pore is modified with a large number of hydroxyl groups (about 50% of the carbon atoms on the surface of the pore wall are connected with hydroxyl groups), which is conducive to the uniform loading of the metal. If the hydroxyl group is not required, it can be removed by high temperature treatment, or it can be converted into other groups by chemical reaction.

The pore structure of nanoporous carbon is regular and orderly and its size is controllable. As a catalyst carrier, it can bring the following three advantages:

1. Compared with the diameter of the hole, the connecting hole between the hole and the hole is smaller. After the catalyst is loaded, it is limited in the hole, and it is not easy to agglomerate and lose, which obviously improves the life of the catalyst.

2. The pore size and the size of the connecting holes are adjustable, and the required pore structure can be precisely designed according to the size of the reactants and products, which significantly improves the catalytic efficiency.

3. There are a large number of micropores and hydroxyl groups on the pore wall of nanoporous carbon powder.

The role of hydroxyl anchoring can construct a catalyst with high stability and low precious metal content, which significantly reduces the amount of precious metals.

Table 1. Nanoporous Toner Parameters

Note: 1. HV stands for high pore volume. The pore structure specifications of high pore volume series products are orderly, and the production process is similar to that of nanoporous carbon film;

1. S stands for small particle size, the particle size is about 1 micron;

2. Due to the thick hole wall, the low pore volume series products have better strength.

1. Nanoporous carbon film

Nanoporous Carbon Scaffolds (NCS). (1) Ingredients

The basic components are carbon 91-95%, oxygen 4-8%, hydrogen 1%, if necessary, the carbon content can be further increased

Step up to 99%. Hydrogen and oxygen exist on the surface of the pore wall in the form of hydroxyl groups. About 50% of the carbon atoms on the surface are connected with hydroxyl groups. The density of the hydroxyl groups is about 10-5mol/m2.

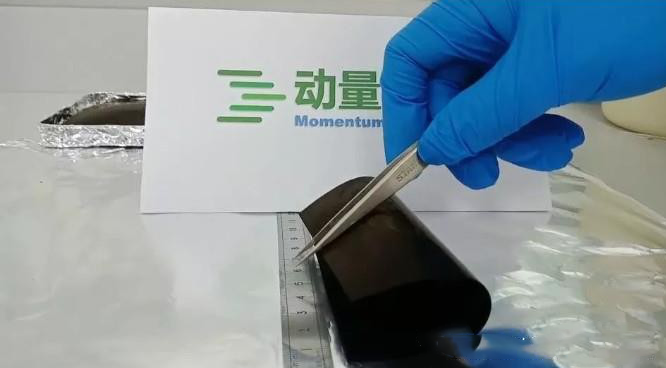

Figure 5 NCS physical photo

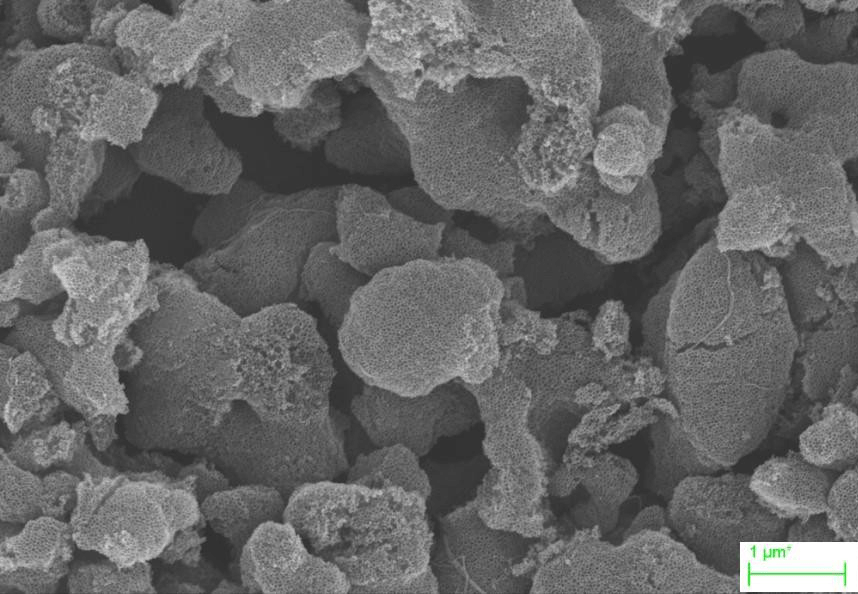

(2) Structure

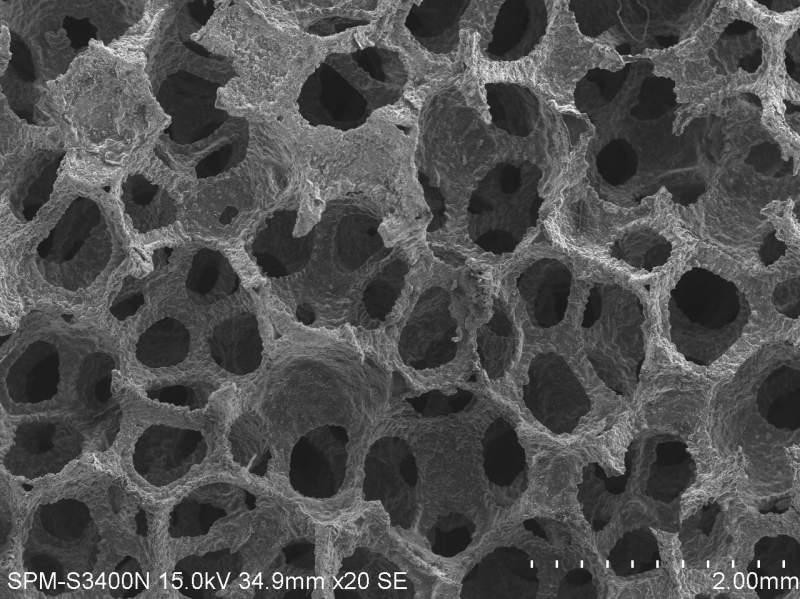

The surface structure of NCS is uniformly arranged nano-holes (Figure 6), and the inside is a three-dimensional interconnected channel structure (Figure 7), and each hole is connected to the surrounding 12 holes (Figure 8). Compared with the diameter of the hole, the connecting hole between the hole and the hole is smaller, showing a unique nanocage structure. On the hole wall

There are also a large number of micropores.

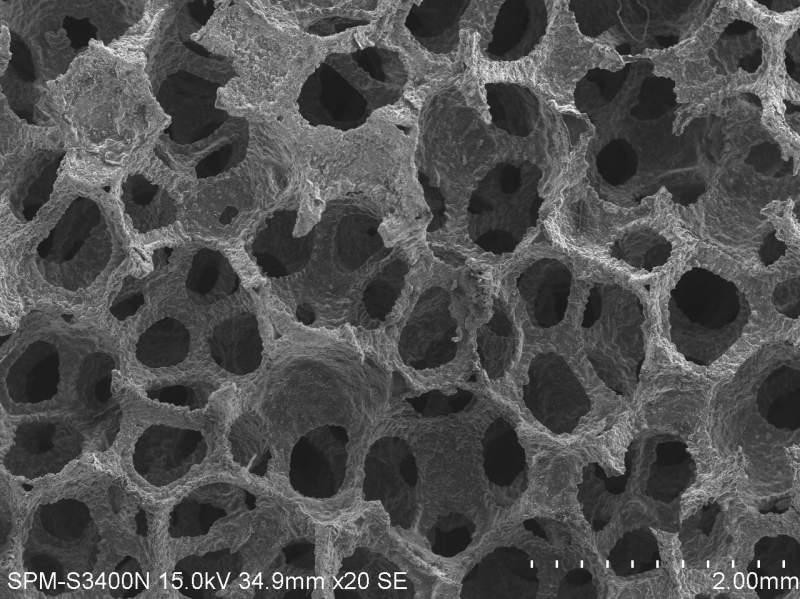

Figure 6 Scanning electron microscope photo of NCS-85

Figure 7 NCS-85 TEM photo

Figure 8 Three-dimensional structure model of NCS

(3) Pore structure parameters

The new nanoporous carbon scaffold film (NCS) has applied for an international invention patent (PCT, WO Patent 2015135069A1), and the scope of the patent protection has covered the Chinese market. At present, we can achieve small batch mass production of 100*100mmNCS.

2. NCS performance

(1) Good conductivity

The carbon content in NCS is between 91-95% and can be further increased to 99% if necessary. It has excellent electrical conductivity (2-10 S/cm).

(2) Orderly internal structure

The internal structure of NCS is a three-dimensional through pore structure. The size and orientation of the pores are very orderly, which is conducive to the diffusion of reactants and products.

(3) Strong controllability

The pore size of NCS is adjustable and can be precisely adjusted within the range of 10-1000 nm. The pore diameter of the connecting hole between the hole and the hole can also be adjusted within a certain range, and it is also possible to introduce a micron-level pore structure into the NCS. The thickness of NCS can be adjusted within the range of 10-100 μm. The inside of the NCS pores can also be modified with chemical groups to achieve hydrophilic and hydrophobic control.

(4) Excellent processing performance

NCS has a certain degree of mechanical strength and toughness, and is easy to process and shape without the need to add a binder.

1. Micron porous carbon block

Microporous Carbon Bricks (MCB for short).

The micron porous carbon block has a pore size of about 500 microns. It has a series of excellent properties such as high strength, high thermal conductivity/conductivity, high temperature resistance, acid and alkali resistance, and easy structure adjustment. It is a lightweight thermal management material and a Materials with thermal conductivity and sound absorption properties can be used in the fields of thermal, acoustic, and RF/EMI signal management.

Compressive strength>3MPa; shear strength>1MPa; bending strength>1MPa; electrical conductivity>30000s/m.

Retail price: 5 yuan/cm3.

Figure 9 MCB scanning electron microscope photo

2. Ultra-high ratio table activated carbon

The specific surface area of the ultra-high ratio activated carbon product is about 3200m2/g, the pore volume is about 2cm3/g, and the average pore diameter is between 2-3nm. The product performance has reached the international advanced level.

The standard is to replace imports and be used in super capacitors, high-end catalysis, lead-carbon capacitors, high-end

|

Warm tip: the products supplied by Beijing Beike Xincai Technology Co., Ltd. are only used for scientific research, not for human body |

| Item ID |

CAS |

ID |

Pack |

Parameter |

Stock |

Make up |

Price |

| BK20191225-01 |

|

|

1g |

氮掺杂碳球,氮含量5% |

100 |

|

$600 |