In order to improve the heat dissipation performance of the metal surface, in order to fully demonstrate the high thermal conductivity, strong radiation ability and excellent mechanical properties of carbon nanotubes, we have developed environmentally friendly functional coatings-water-based carbon nanotube heat dissipation coatings and inks.

Electronic components generate a lot of heat during operation. In order to dissipate heat as quickly as possible, metal heat sinks are usually installed. However, the thermal radiation coefficient of the metal surface is very low. Without convective heat transfer, the heat collected on the metal surface is difficult to radiate. Improving the heat radiation efficiency of metal surfaces through coating technology is an important way to improve the heat dissipation performance of metal materials. With the rapid development of the electronics industry today, heat-dissipating coatings have received widespread attention.

Carbon nanotubes (CNTs) are the most ideal functional fillers for heat dissipation coatings. CNTs are one of the best thermally conductive materials known in the world. CNTs are one-dimensional nanomaterials with a large specific surface area. They are known as the blackest substances in the world, and their emissivity is close to 1. Compared with other heat-dissipating fillers in granular form, nano-fibrous CNTs are easier to form a thermally conductive network, and have a significant effect of strengthening and toughening the coating. When the coating is very thin, such as 5-10 microns, it can form a uniform, smooth and mechanical Excellent performance film.

Carbon nanotube heat-dissipating paint is distinguished by its strong radiation ability, thin coating, and low thermal resistance, which can stimulate the resonance effect on the surface of the metal radiator, significantly improve the far-infrared emission efficiency, and accelerate the rapid heat dissipation from the surface of the radiator. It is suitable for film heat dissipation, metal substrate heat dissipation, LED lamp base heat dissipation, and electrical appliance shell heat dissipation.

JCRHC-1, with a low curing temperature, is suitable for transfer coating and gravure printing of copper foil and aluminum foil, and spraying of various metal parts to meet the application requirements of room temperature drying.

JCRHC-2, the curing temperature is not less than 130℃, the coating hardness is higher, and the adhesion is better. It is suitable for spraying various metal parts.

JCRHC-3, a water-based heat-dissipating ink for screen printing, suitable for local heat dissipation requirements of metal parts.

In addition to providing heat dissipation solutions for various metal substrates, we can also provide a variety of heat dissipation solutions for plastic substrates, including: PET, PC, PS, PA, ABS, etc.

【Performance】

|

Paint name

|

JCRHC-1

|

JCRHC-2

|

JCRH3-3

|

|

Paint type

|

Low temperature drying water-based paint

|

Medium temperature baking type water-based paint

|

Medium temperature baking type water-based ink

|

|

Coating drying conditions

|

Dry at room temperature or 80℃ for 3-5 minutes

|

130°C, 15-20 minutes

|

130°C, 15-20 minutes

|

|

Coating color

|

black

|

black

|

black

|

|

Thermal conductivity of the coating in the vertical direction (W/m.K)

|

0.4

|

0.4

|

0.4

|

|

Coating horizontal thermal conductivity (W/m.K)

|

18.0-20.0

|

18.0-20.0

|

18.0-20.0

|

|

Coating emissivity (%)

|

96-98

|

96-98

|

96-98

|

|

Recommended coating thickness (μm)

|

5-10

|

5-10

|

5-10

|

|

Coating surface resistance (Ω)

|

106-108

|

108-1010

|

108-1010

|

|

Coating pencil hardness

|

H-2H

|

2H-3H

|

2H-3H

|

|

Theoretical temperature resistance (℃)

|

150

|

200

|

200

|

|

Construction method

|

Spraying, brushing, transfer coating, 20m2/kg

|

Spraying, 20m2/kg

|

200 mesh screen printing, 20m2/kg

|

|

Scope of application

|

Copper foil heat sink

Aluminum foil heat sink

|

Avoid sandblasting of the substrate

Instead of aluminum plate anodized blackening treatment, LED lamp base heat dissipation

|

Heat dissipation of small area sheet surface

|

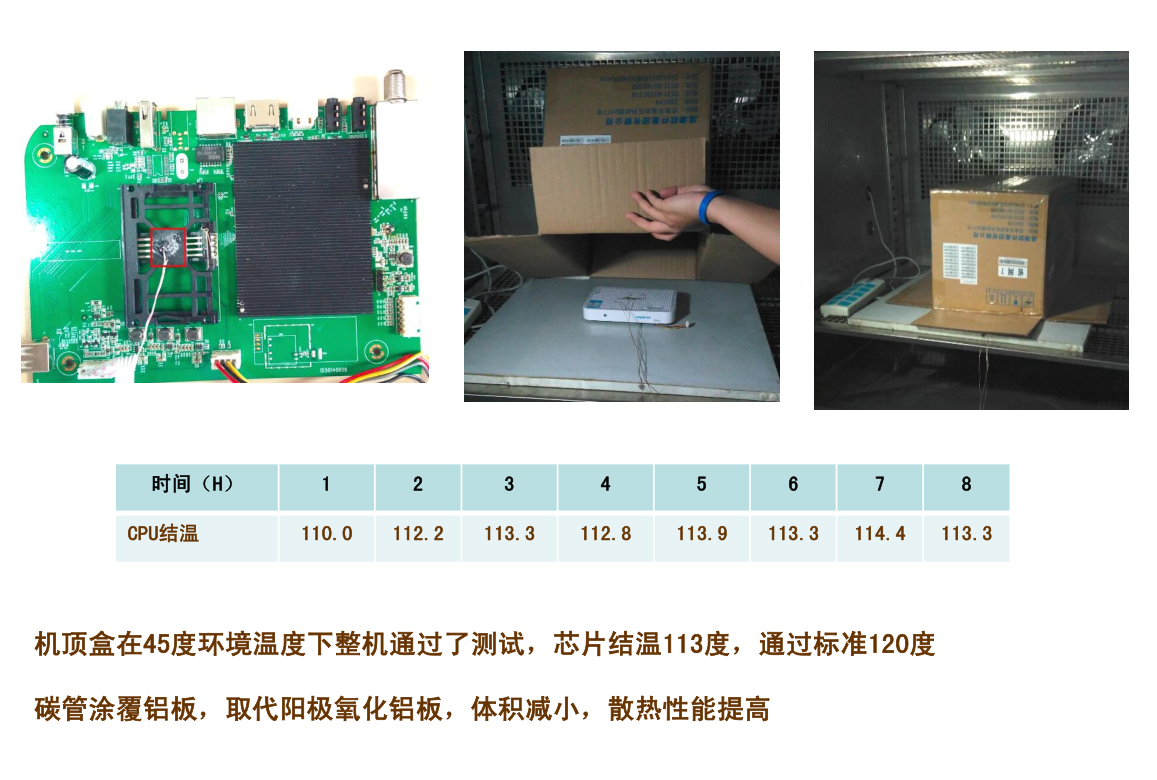

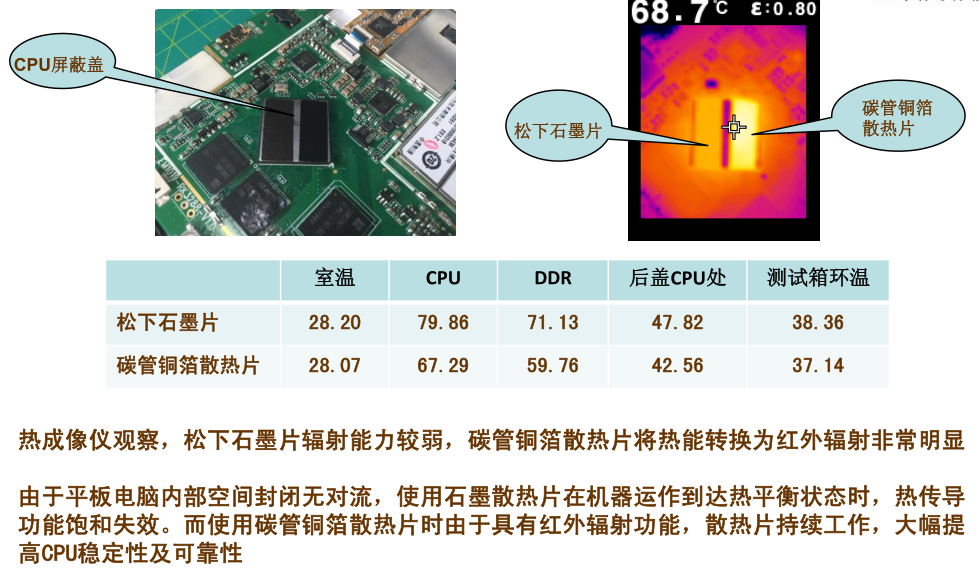

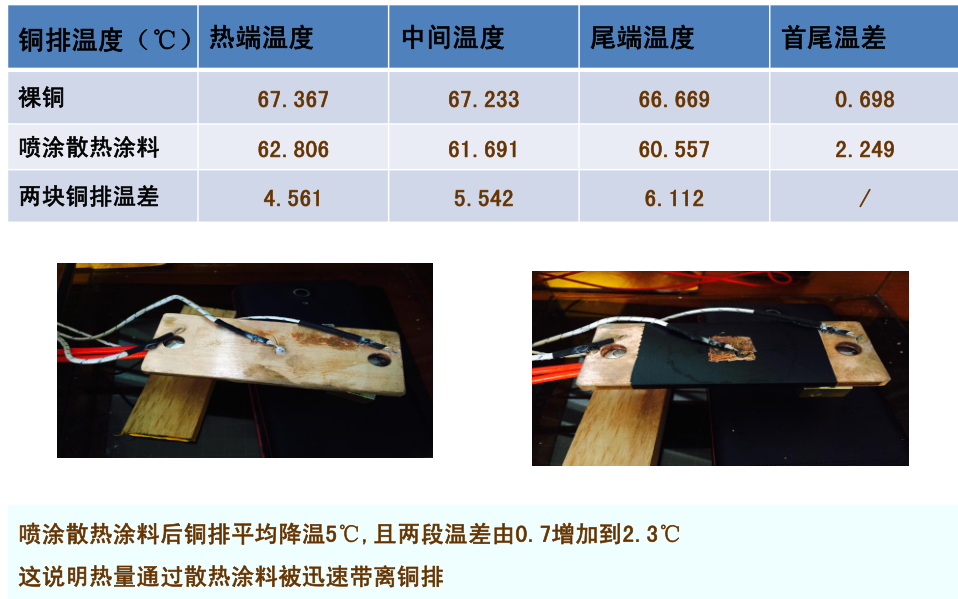

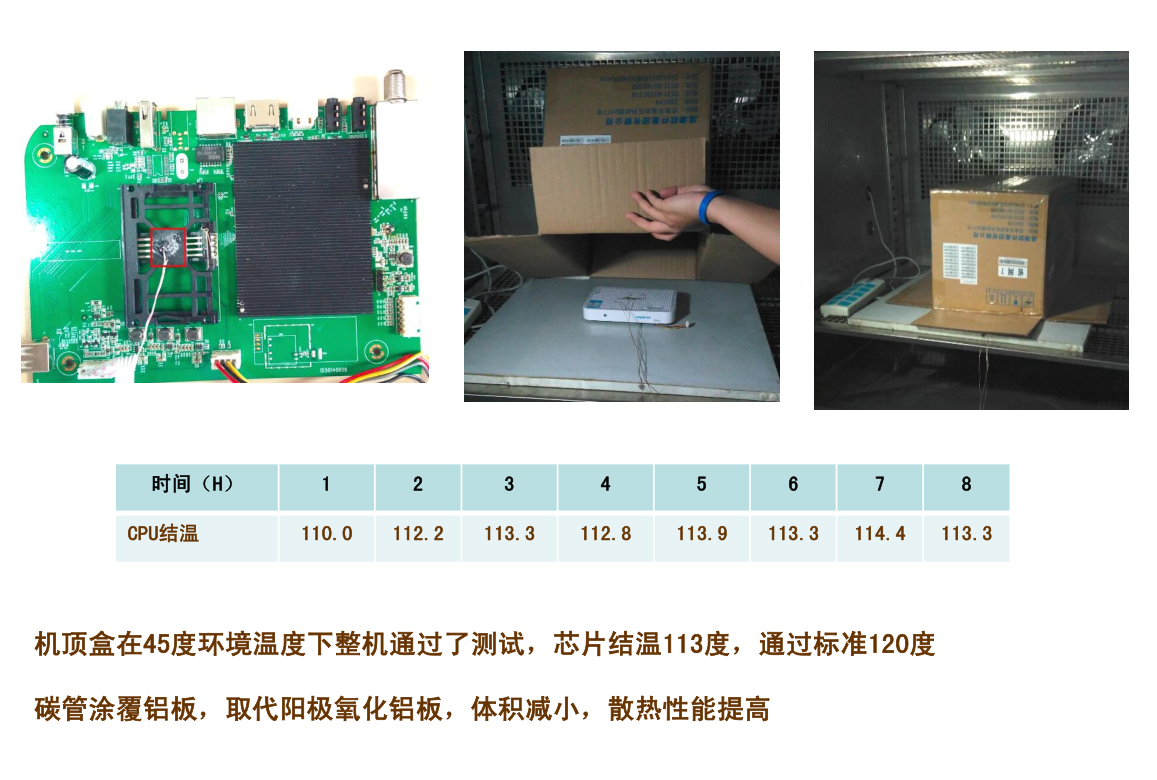

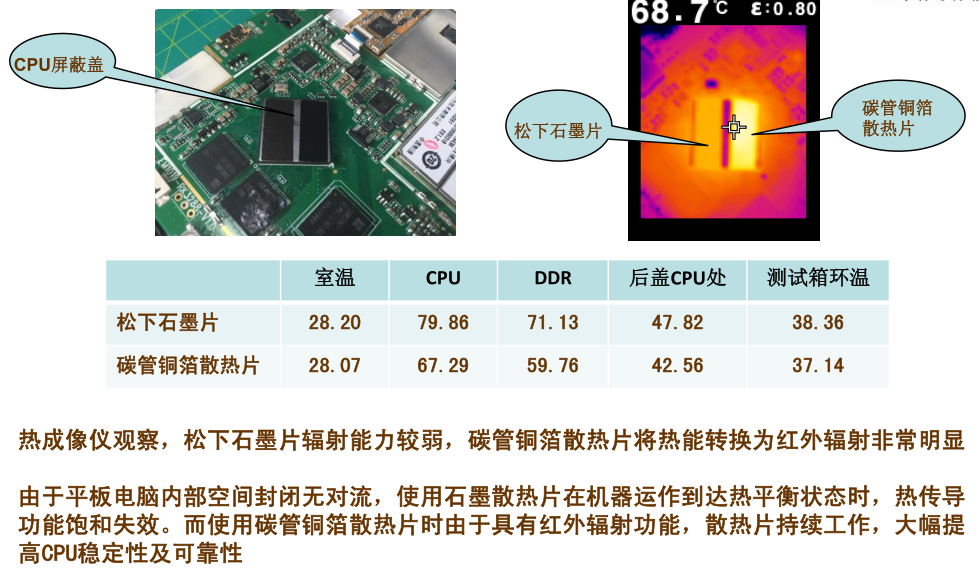

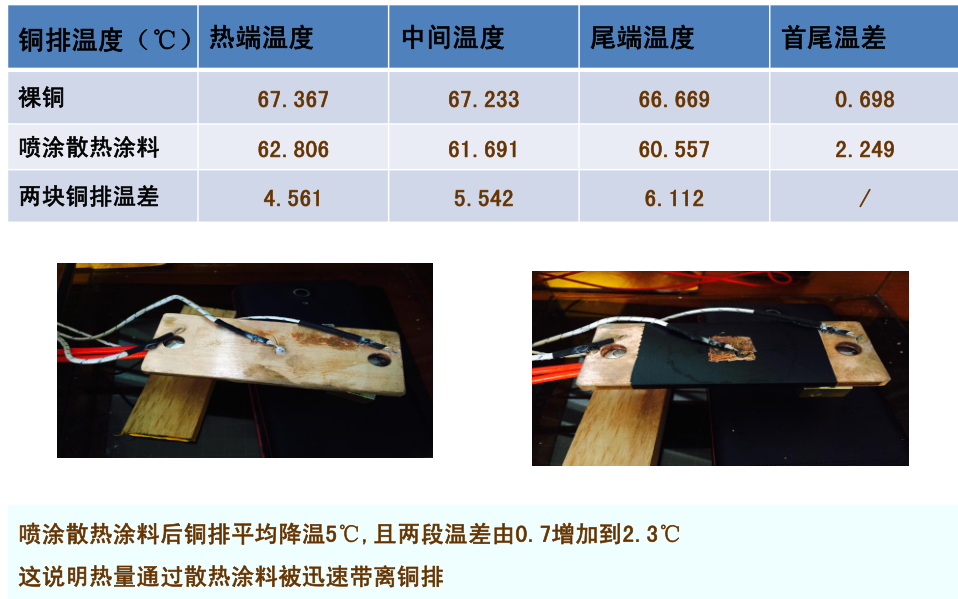

应用实例

|

Warm tip: the products supplied by Beijing Beike Xincai Technology Co., Ltd. are only used for scientific research, not for human body |

| Item ID |

CAS |

ID |

Pack |

Parameter |

Stock |

Make up |

Price |

| BKJCRHC-01 |

|

BKJCRHC |

|

JCRHC-1 1kg |

100 |

|

$50 |

| BKJCRHC-02 |

|

BKJCRHC |

|

JCRHC-2 1kg |

100 |

|

$50 |

| BKJCRHC-03 |

|

BKJCRHC |

|

JCRHC-3 1kg |

100 |

|

$50 |