product information:

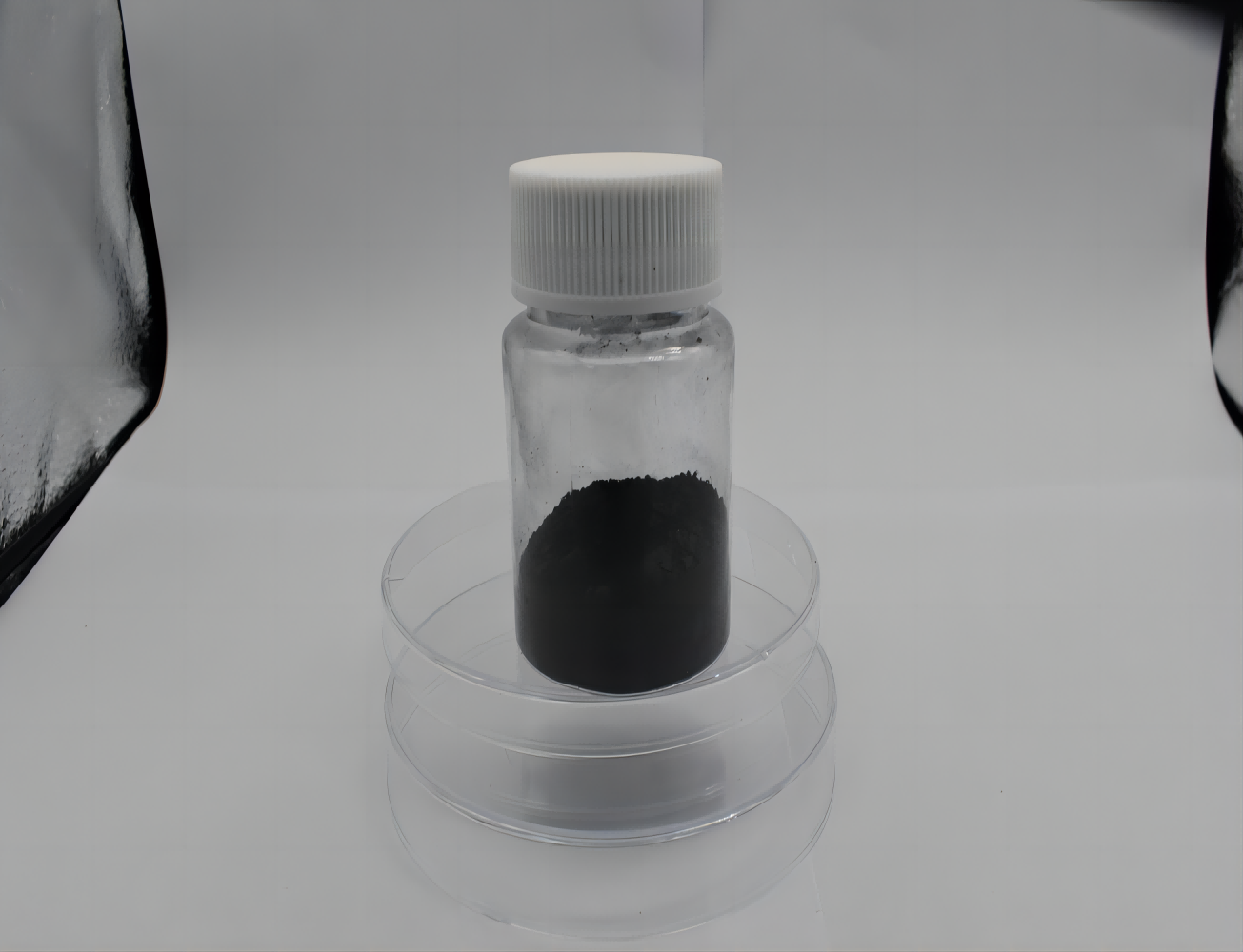

Name: Dimagnesium Silicide

Purity: ≥99.5 single phase

Particle size: D50: 5~10 microns

Melting point: 1102°C

Density: 1.94g/cm3

Uses: Metal silicide materials have many excellent thermal, electrical and mechanical properties. Magnesium silicide is the only stable compound in the Mg-Si binary system. It has the characteristics of high melting point, high hardness, and high elastic modulus. It is a narrow band Chen n-type semiconductor materials have important application prospects in the fields of optoelectronic devices, electronic devices, energy devices, lasers, semiconductor manufacturing, and constant temperature control communications.

The process of Mg2Si film can be well compatible with the si process, so the Mg25i/si heterojunction structure has great research value. This article uses magnetron sputtering methods respectively.

Prepare environment-friendly Mg2Si films on s substrates and insulating substrates to study the influence of sputtering Mg film thickness on the quality of Mg2si films, and on this basis, surround Mg2Si

Research on the fabrication process of base heterojunction LED devices and the electrical and optical properties of Mg2Si films. First, use the magnetron sputtering method at room temperature.

The Mg film is deposited on the substrate, the si film and the Mg film are deposited on the insulating glass substrate, and then the Mg2Si film is prepared by heat treatment in a low vacuum (10-1Pa-10-2Pa) atmosphere.

XRD and SEM results show that annealing at 400C for 4h, a single-phase Mg2Si film is prepared, and the prepared Mg2si film has dense, uniform and continuous grains, and the surface is flat.

The crystallinity is good. Secondly, the influence of the thickness of the Mg film on the growth of the Mg2Si semiconductor film and the relationship between the thickness of the Mg film and the thickness of the Mg2SsI film formed after annealing are studied. The results show that when the thickness of the Mg film is 2.52 μm and 2.72 μm, it shows good crystallinity and flatness. The thickness of the Mg2Si film increases with the increase of the Mg thickness by approximately

0.9-1.1 times the thickness of Mg. This research will play an important role in guiding the design of devices based on Mg2Si films. Finally, the preparation of Mg2Si-based heterojunction light-emitting devices was studied.

Mg2Si/Si and S/Mg2Si/Si heterojunction LED devices were prepared on S substrate, using four-probe test system, semiconductor characteristic analyzer, steady-state transient fluorescence spectrometer, etc.

The equipment conducts electrical and optical properties research on Mg2Si/i and Si/Mg2Si/Si heterojunctions. The results show that the resistivity and sheet resistance of the Mg2S film increase with the thickness of Mg2Si.

Increase and decrease; Mg2Si/Si, S/Mg2Si/Si heterojunctions show good unidirectional conduction characteristics, and the turn-on voltage of Si/Mg2Si/Si double heterojunction structure is relatively large, about 3 V;

The Mg2Si/n-si heterojunction device has the highest photoluminescence intensity when the wavelength is 1346 nm. The Mg2Si film prepared on the insulating substrate has the highest photoluminescence intensity when the wavelength is 1346 nm;

Comparing the photoluminescence of Mg2Si films prepared on different substrates, the Mg2Si films prepared on high-purity quartz substrates have better luminescence performance and have infrared monochromatic luminescence characteristics.

|

Warm tip: the products supplied by Beijing Beike Xincai Technology Co., Ltd. are only used for scientific research, not for human body |

| Item ID |

CAS |

ID |

Pack |

Parameter |

Stock |

Make up |

Price |

| BK2020112405-01 |

22831-39-6 |

BK2020112405 |

100g/瓶 |

Si 36%~38% |

100 |

|

$250 |