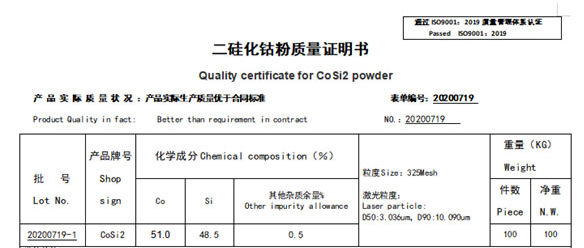

product information:

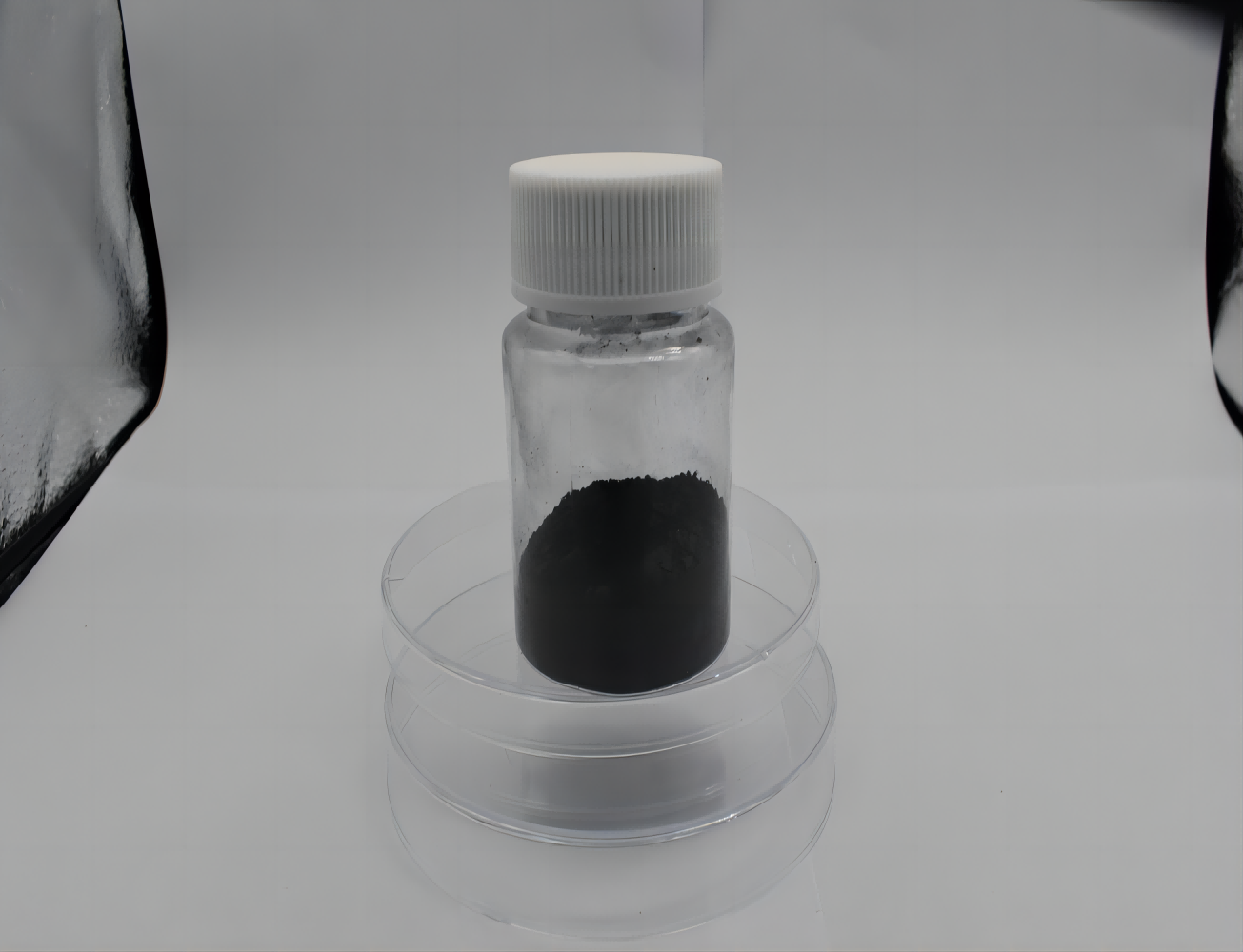

Name: Cobalt Disilicide

Purity: ≥99.5 single phase

Particle size: D50: 5~10 microns

Cobalt disilicide

Chemical formula CoSi2. The molecular weight is 115.11. Dark brown orthorhombic crystals. Melting point 1277°C,

The relative density is 5.3. It can be oxidized at 1200°C and corrode its surface; react with fluorine at low temperatures; and react with chlorine at 300°C. It can be corroded by hydrogen fluoride, dilute, concentrated nitric acid and sulfuric acid, and can also be violently corroded by molten alkali. It acts slowly with boiling concentrated hydrochloric acid. CoSi2 has low resistivity,

Good thermal stability, currently widely used as contacts in large-scale integrated circuits. And CoSi2 has a crystal structure similar to Si, so an epitaxial CoSi2/Si structure can be formed on a Si substrate to study the interface characteristics of epitaxial metal silicon. Silicide nanostructures have potentially important applications in a series of nanoelectronics: semiconductor silicide nanostructures (FeSi2) can be used to prepare nanoelectronic active devices, and they may have very important applications in silicon-based nanolight emitting devices. ; Metallic silicides (CoSi2, NiSi2) can be used as nanowires in future quantum computers and fault-tolerant terahertz nanocircuit computers. Because epitaxial silicide wires can be prepared on silicon substrates, their performance is because there are no crystal grains. The boundary will be much higher than that of ordinary metal nanowires; metallic nanostructures can also be used as nanoelectrodes for one molecule or several molecules in molecular electronics.

In the process of semiconductor components, a low-resistance cobalt disilicide (CoSi2) layer is often formed on internal electrical connection points such as gate, source, or drain. -Generally speaking, the manufacturing method of cobalt disilicide is to first form a metal cobalt (Co) layer on a silicon-containing substrate, and then undergo two annealing treatments

(anneal ingtreatment) to convert cobalt into cobalt disilicide. Among them, the first annealing treatment is to diffuse cobalt into the silicon-containing substrate to form a cobalt silicide (CoSi) layer. The second annealing treatment is to convert the cobalt silicide layer into low-resistance cobalt disilicide, thereby reducing the resistance of the component.

|

Warm tip: the products supplied by Beijing Beike Xincai Technology Co., Ltd. are only used for scientific research, not for human body |

| Item ID |

CAS |

ID |

Pack |

Parameter |

Stock |

Make up |

Price |

| BK2020112502-01 |

12017-12-8 |

BK2020112502 |

100g/瓶 |

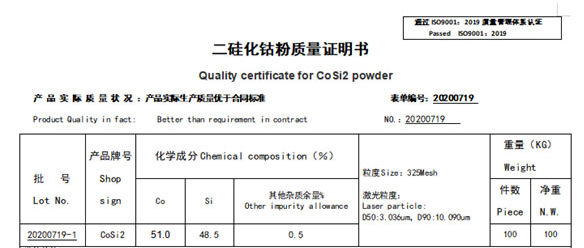

Si 48%~50% |

100 |

|

$125 |