product information:

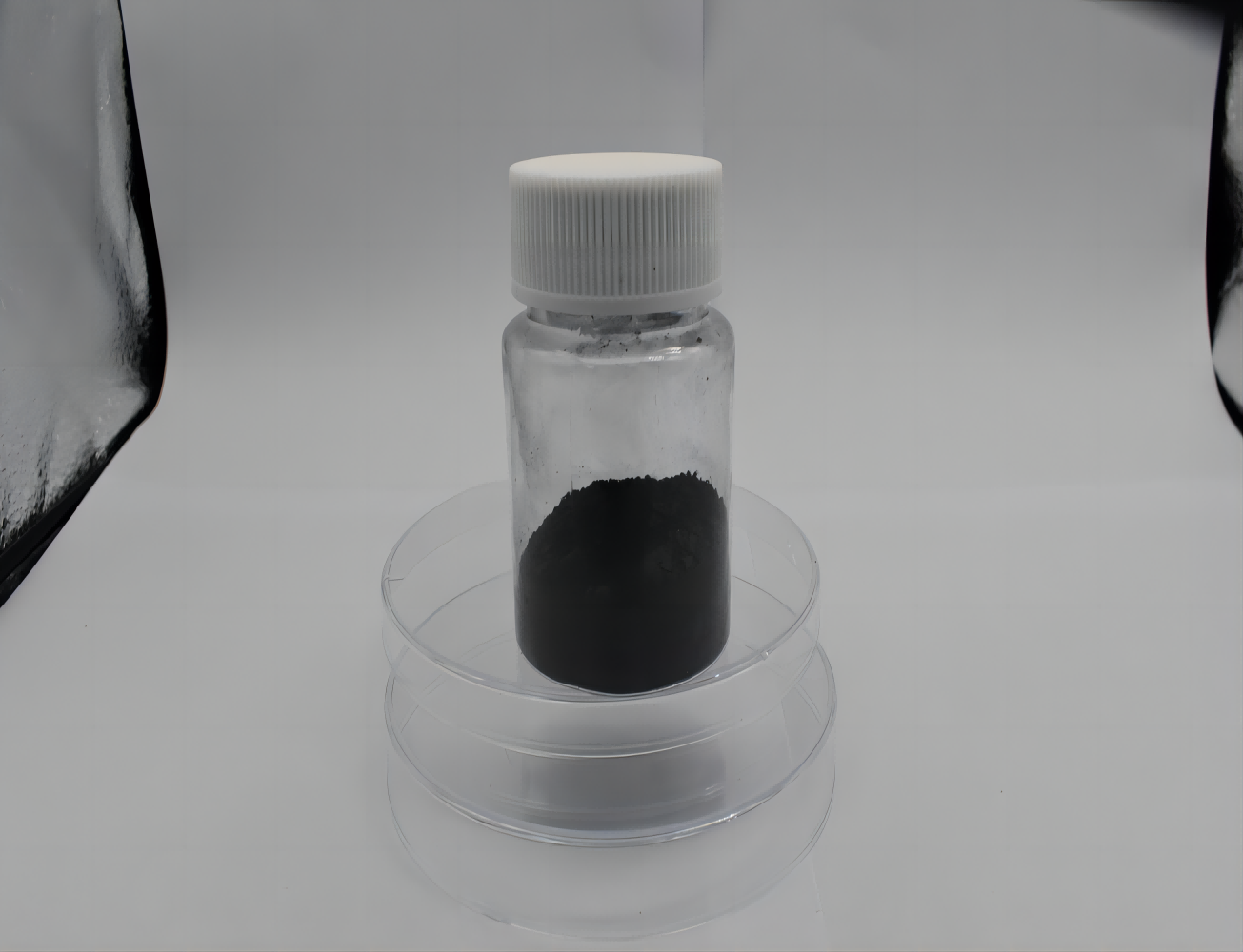

Name: Aluminum Diboride

Purity: ≥99.5 single phase

Particle size: D50: 5~10 microns

Melting point: 1655°C

Density: 3.19g/cm3

Properties: dark gray powder

Application: Cermet

Aluminum boride (AIB2) is a binary compound formed by aluminum and boron. It is a gray-red solid under normal temperature and pressure. It loses its surface gloss when heated. It is stable in cold dilute acid, and decomposes in hot hydrochloric acid and nitric acid. It is obtained by mixing fine powders of aluminum and boron after heating and reacting. It is one of two compounds of aluminum and boron--, the other is AIB12, which is usually called aluminum boride. AIB12 is a black shiny monoclinic crystal with a specific gravity of 2.55 (18°C)

It is insoluble in water, acid and alkali, decomposes in hot nitric acid, and is obtained by melting together boron trioxide, sulfur and aluminum. Structurally, B atoms form graphite-like sheets with Al atoms between them, which is very similar to the structure of magnesium diboride. The single crystal of AIB2 exhibits metallic conductivity on an axis parallel to the hexagonal plane of the substrate. Boron-aluminum composite material is protected by boron fiber or tape

Coated boron fiber reinforced aluminum or aluminum alloy. The volume content of boron fiber is generally about 45%" 55%. Low specific gravity and high mechanical properties. The longitudinal tensile strength of unidirectionally reinforced boron-aluminum composites varies with the process and raw materials. The difference is about 1.2~1.7GPa, and the elastic modulus is about 200^240GPa. The longitudinal specific elastic modulus and specific strength are about 3~5 times and 3^4 times that of titanium alloy duralumin and alloy steel, respectively. Good fatigue performance , It still has high strength below 400°C. It has been used in turbojet engine fan blades and aviation, aerospace vehicles and satellite structures. The hot-press diffusion bonding method is used to manufacture plates, profiles and parts with more complex shapes; it can also be used Continuous casting method to manufacture various profiles.

|

Warm tip: the products supplied by Beijing Beike Xincai Technology Co., Ltd. are only used for scientific research, not for human body |

| Item ID |

CAS |

ID |

Pack |

Parameter |

Stock |

Make up |

Price |

| BK2020112510-01 |

12041-50-8 |

BK2020112510 |

100g/瓶 |

B 44%~45% |

100 |

|

$500 |