In order to meet the growing demand for grid-scale energy storage, electric vehicles and wearable electronic devices, researchers are committed to exploring energy storage devices that can achieve high quality and volume capacity. Thanks to higher theoretical energy density (2600 Wh kg-1; 2800 Wh L-1), cost-effectiveness and environmental friendliness, lithium-sulfur batteries (LSBs) are considered to be a type of potential in many energy storage systems Alternative options. However, commercial lithium-sulfur batteries are still limited by low sulfur usage, poor cycle performance, and insufficient rate performance. This is mainly due to the insulating nature of sulfur, the shuttle effect of soluble lithium polysulfide and the slow Kinetic characteristics of sulfur chemical reactions. Exploring high-efficiency sulfur host materials is essential for the realization of lithium-sulfur batteries with excellent mass and volume capacity.

Suitable sulfur host materials have the following characteristics: i) good electrical conductivity to ensure the rapid transfer of electrons; ii) optimized design of the matrix to ensure ion transport and sulfur loading; iii) sufficient active sites for polymerization The adsorption of lithium sulfur and the nucleation of Li2S; iv) high tap density helps to increase volume capacity.

MXene, as a kind of emerging 2D transition metal carbide/carbonitride, has some unique properties, such as outstanding electronic conductivity, hydrophilicity and porosity. In the process of etching with HF, some metal oxides are usually formed on the surface. Up to now, there have been some studies on how to control and utilize the application of these metal oxides in energy-related fields, because these in-situ generated oxides will be beneficial to the improvement of performance.

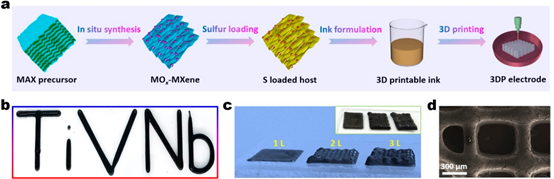

Recently, Professor Ruizhi Yang and Professor Sun Jingyu of Soochow University published a research paper titled Universal in Situ Crafted MOx-MXene Heterostructures as Heavy and Multifunctional Hosts for 3D-Printed Li-S Batteries in the internationally renowned academic journal ACS Nano, reporting A method that uses 3D printing technology to grow oxides on the surface of MXene to form a heterojunction. As a multifunctional host, it can obtain good battery performance through simultaneous fixation and conversion of polysulfides.

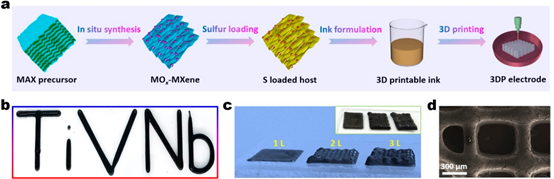

Figure 1. The synthesis process of MOx-MXeneMOx-MXene (M: Ti, V and Nb).

Figure 2. Morphology and composition characterization of MOx-MXene (M: Ti, V and Nb) heterojunction.

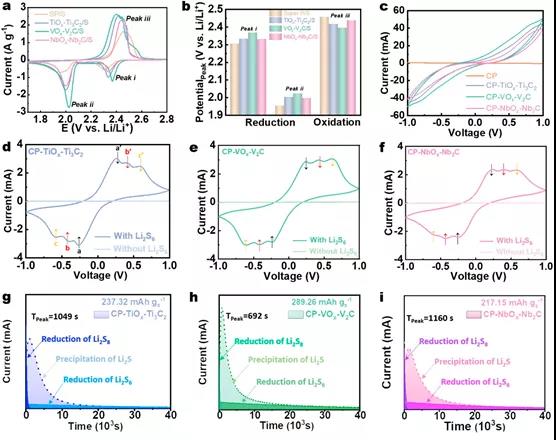

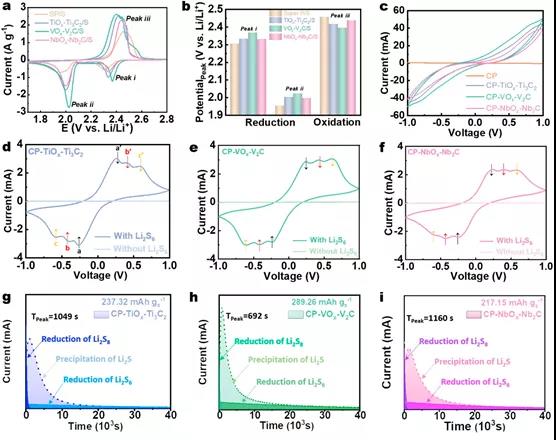

Figure 3. Kinetic analysis of sulfur redox.

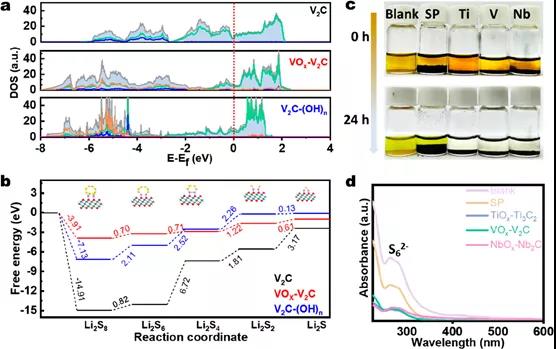

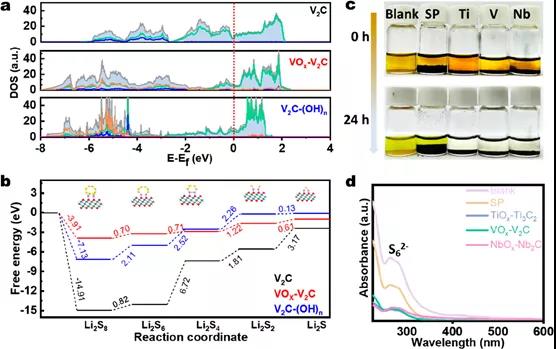

Figure 4. Theoretical simulation and adsorption test.

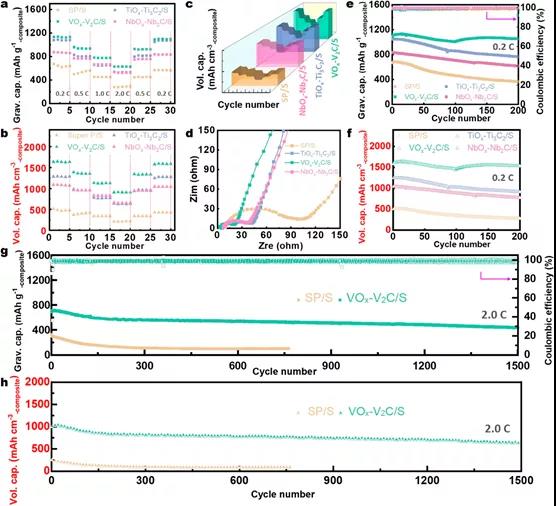

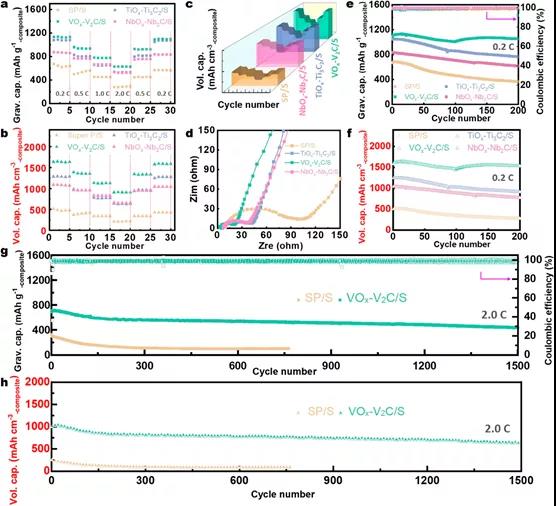

Figure 5. Electrochemical performance test of MOx-MXene/S cathode in lithium-sulfur battery applications.

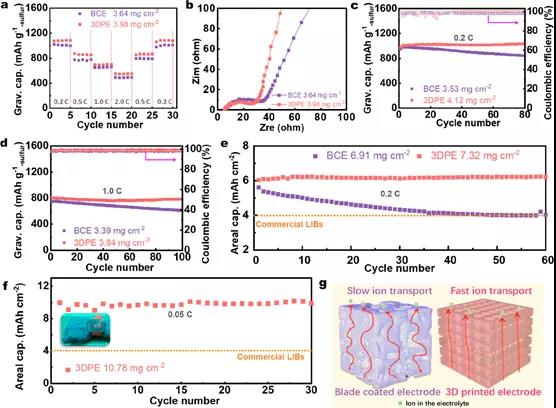

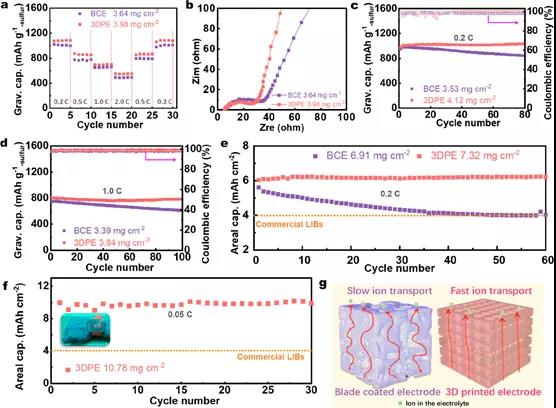

Figure 6. Comparison of electrochemical performance test of 3D printed VOx-V2C/S electrode in lithium-sulfur battery application and smear electrode.

This paper presents an efficient and general method for in-situ preparation of MOx-MXene (M: Ti, V and Nb) heterostructures as a high tap density sulfur host material for lithium-sulfur batteries. The derived MOx-MXene has been proved to have good immobilization and catalytic ability for lithium polysulfide; combined with its higher tap density, the VOx-V2C/S cathode used in lithium-sulfur batteries can produce a mass specific capacity of 1135.16 mAh g-1 And the volume specific capacity of 1645.98 mAh g-1. More importantly, 3D printing technology can prepare electrode materials with high surface capacitance and high sulfur loading. The 3DPE electrode with a mass load of 10.78 mg cm-2 can achieve a surface capacitance of 9.74 mAh g-1 at 0.05 C. The electrode structure prepared by 3D printing is beneficial to promote the kinetics of sulfur redox reaction and the diffusion of ions, and at the same time can alleviate the volume expansion that occurs during the charge and discharge process.

Literature link:

https://dx.doi.org/10.1021/acsnano.0c07999A

Source: MXene Frontier

This information is from the Internet for academic exchanges. If there is any infringement, please contact us and delete it immediately