【Research Background】

【Research Background】

Zinc-iodine conversion batteries store/supply energy through the reversible conversion of halogen in the elemental state and ionic state, and have inherent advantages of low cost and high voltage. Thanks to the complete phase transition and electronic gains and losses, the battery exhibits extremely low voltage attenuation characteristics and a flat discharge plateau curve. However, the system still has many key issues to be solved. Elemental iodine is naturally insulating, and its reversible redox transformation must rely on an external conductive carrier to transfer electrons. Usually porous carbon materials play this role. Through CVD, immersion, adsorption and other processes, the iodine elemental active material is compounded with the porous host. The physical combination often leads to uneven distribution of active materials on the conductive carrier, poor interaction between hosts, and inefficient electron conduction. In addition, when the affinity between the host and the host is insufficient to cope with the dissolution and shuttle of polyiodide in the electrolyte during the reaction, the battery often exhibits poor cycle life and poor self-discharge.

【Introduction】Recently, Professor Chunyi Zhi and Professor Fan Jun from the City University of Hong Kong and the research group of Ningbo Institute of Materials Research Huang Qing prepared a composite MXene-I2 halogen cathode material using conductive MXene material as a carrier and a new type of electrochemical deposition process , And reported the excellent electrochemical performance of the material in the water-based zinc battery system. Iodine ions are uniformly inserted between the nano-layers of the MXene material under the drive of an electric field and are converted into iodine in situ at a high potential. Multiple spectroscopic characterization combined with DFT calculation and simulation revealed the natural affinity of MXene matrix for multiple iodides (iodide ions, polyiodides, and elemental iodine), as well as the efficient electron transfer characteristics between the two. Based on this, MXene-I2//Zn battery exhibits excellent conversion kinetics and anti-fading characteristics. The article was published in the top international journal Advanced Materials. Li Xinliang is the first author of this article.

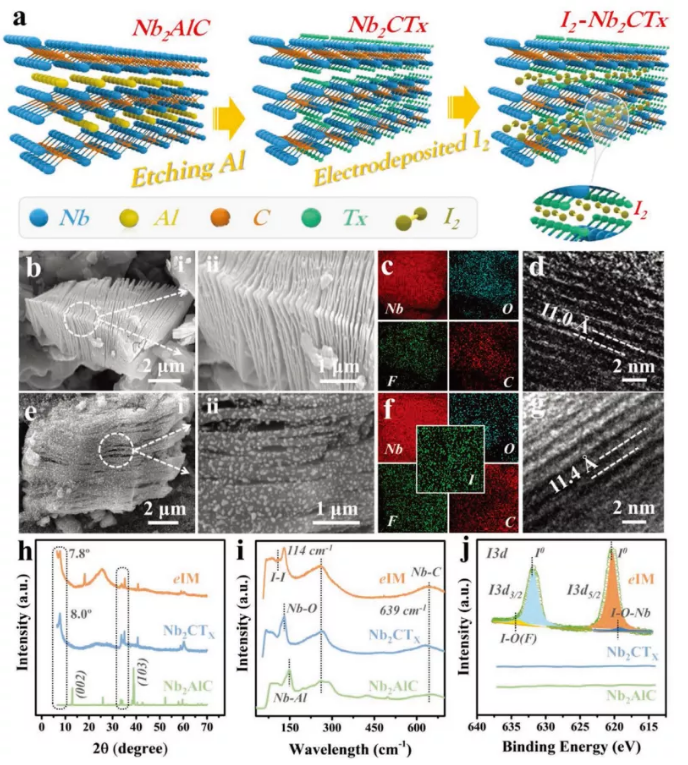

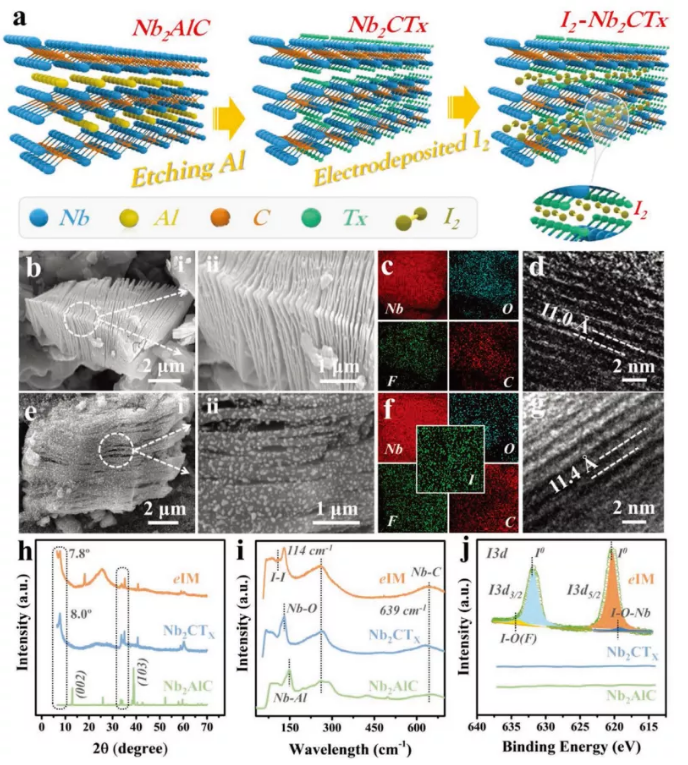

[Content expression] In order to achieve a uniform load of iodine, the process is particularly critical. In this paper, an electrodeposition process is designed, which uses iodide ions in the electrolyte as raw materials through in-situ oxidation to realize the uniform distribution of iodine between the MXene layers. The reason for choosing iodide ions instead of iodine is because of its smaller ion radius and matching the positive charge of the applied electric field.

Figure 1: Synthesis and characterization of MXene-I2 composite electrode. a) Electrodeposition process flow. b) SEM photo of the original layered MXene material. c) EDX spectrum of MXene material. d) HRTEM photo of MXene material. e) SEM photo of MXene-I2 composite electrode. f) EDX spectrum of MXene-I2 composite electrode. g) HRTEM picture of MXene-I2 composite electrode. h) XRD spectrum. i) Raman spectrum. j) I3d xps spectrum.

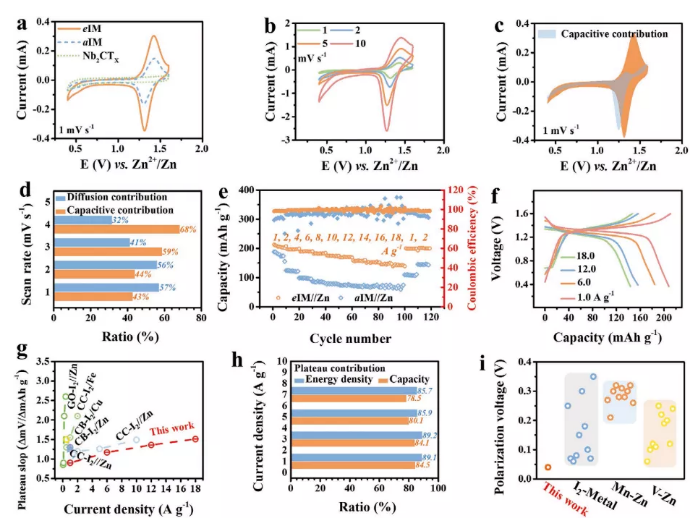

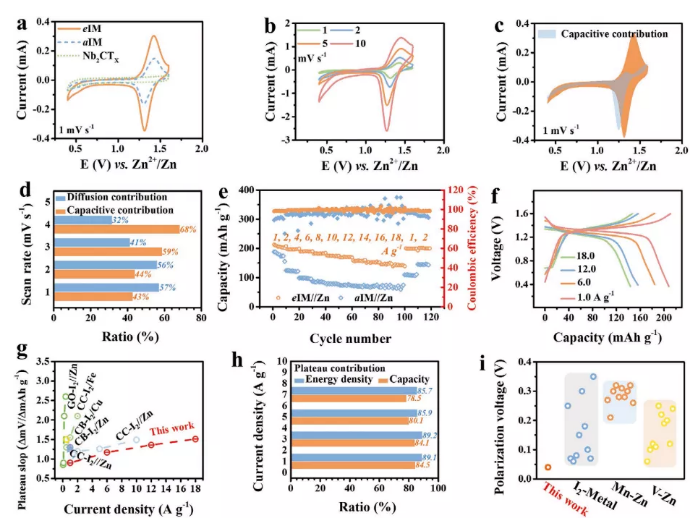

Figure 2: Electrochemical performance of MXene-I2 composite electrode. a) CV curve of MXene-I2 composite electrode and comparative sample. b) CV curve of MXene-I2 composite electrode at different scanning speeds. c) Schematic diagram of capacitive contribution at 1 mV s-1 sweep speed. d) Contrast of capacitive/diffusion contribution at different scanning speeds. e) The rate performance of the MXene-I2 composite electrode and the comparative sample. f) Charge and discharge curve corresponding to rate performance. g) Comparison of voltage plateau slopes. h) The contribution ratio of the voltage plateau area to the energy density and capacity. i) Polarization voltage comparison.

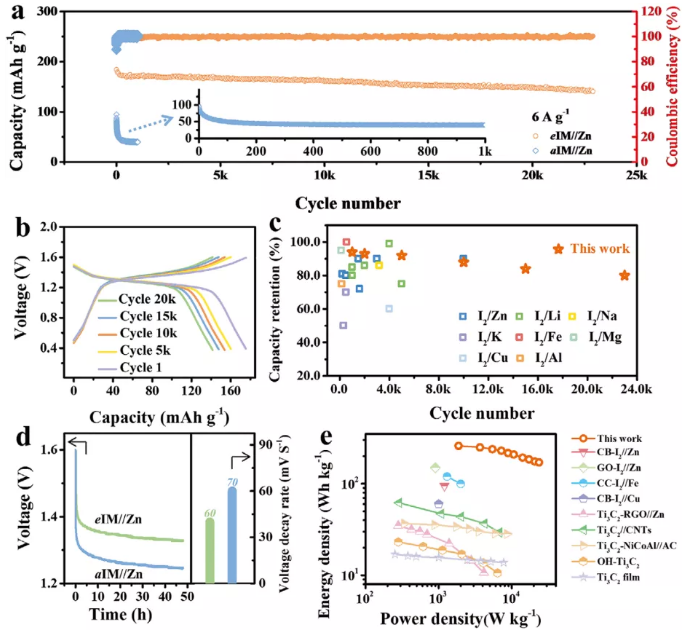

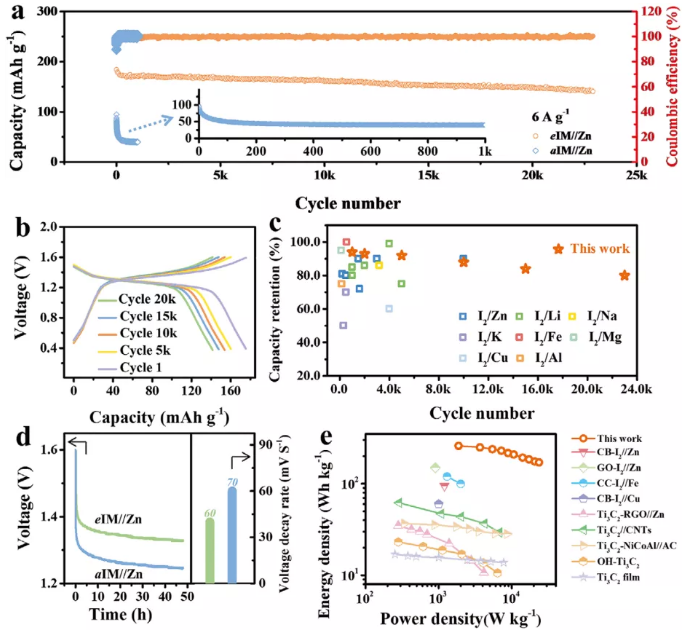

Figure 3: Inspection of cycle stability and self-discharge performance. a) Long cycle performance of MXene-I2 composite electrode. b) Charge and discharge curves corresponding to different cycle intervals. c) Comparison chart of cycle life vs capacity retention rate. d) Voltage self-decay curve and rate. e) Ragone comparison chart.

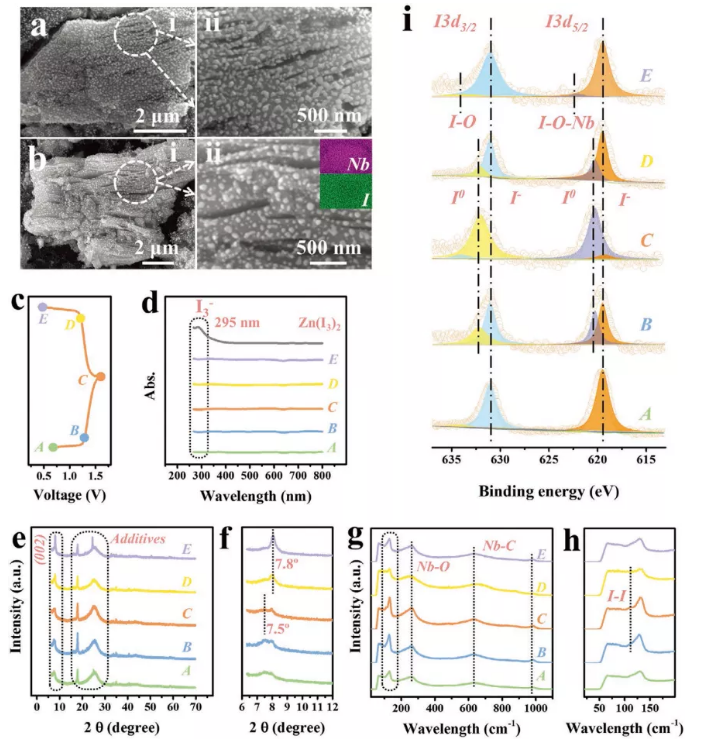

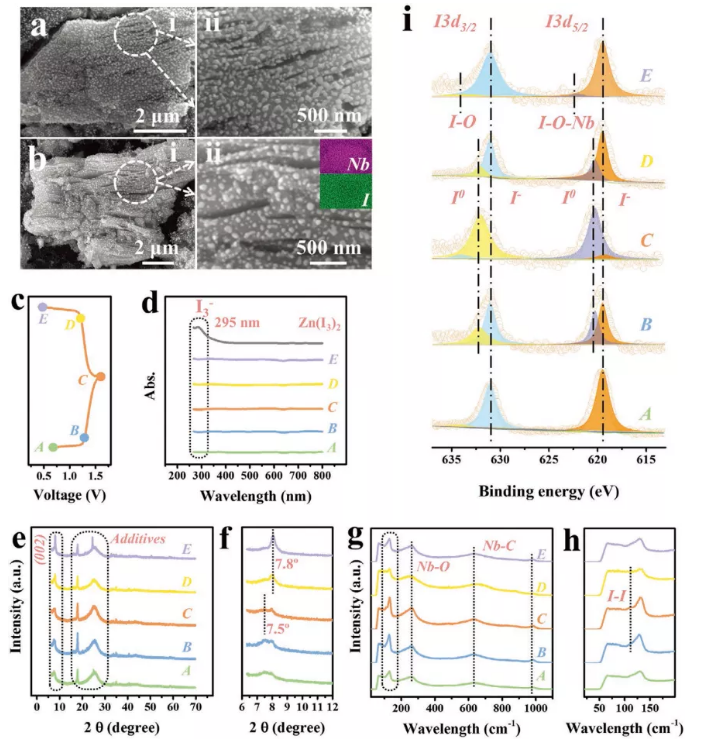

Figure 4: Mechanism analysis. a) SEM picture of MXene-I2 composite electrode after 10,000 cycles. b) SEM picture of MXene-I2 composite electrode after 20,000 cycles. c) Charge and discharge curve with voltage mark. d) UV-vis spectra of electrolyte under different circulation conditions. e) XRD spectra of MXene-I2 composite electrode in different cycles. f) The (002) crystal plane region enlarged in the XRD spectrum. g) Raman spectra of MXene-I2 composite electrode in different cycles. f) The 25-200 cm-1 wavenumber region enlarged in the Raman spectrum.

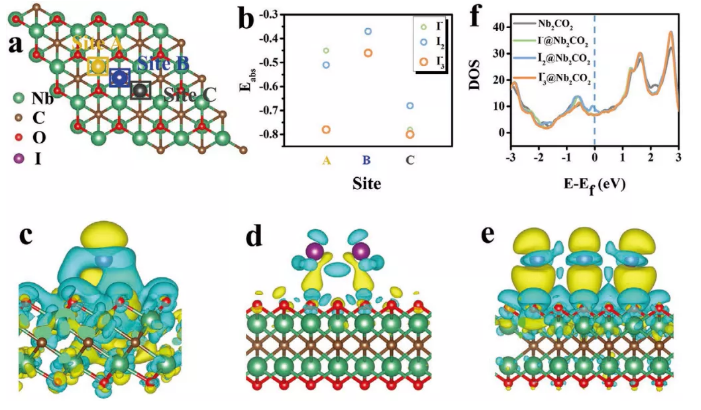

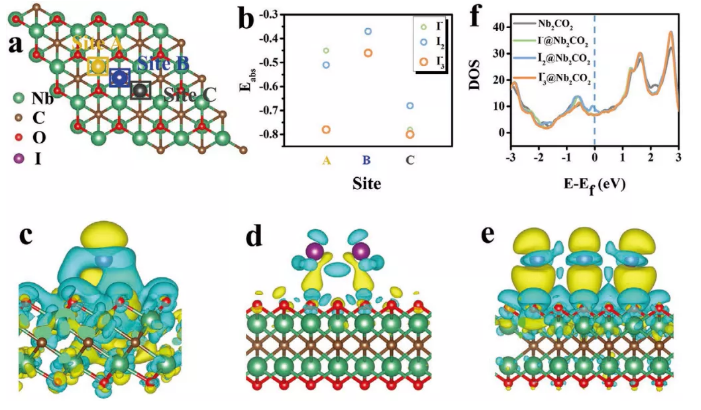

Figure 5: DFT simulation. a) Schematic diagram of MXene lattice and possible adsorption sites. b) The adsorption energy of iodide at different adsorption sites. The final optimized differential charge density model at the Nb adsorption site c) Iodine ion, d) Iodine element, e) Iodine triion. f) DOS density curve of MXene carrier before and after adsorption of iodide.

Xinliang Li, Na Li, Zhaodong Huang, Ze Chen, Guojin Liang, Qi Yang, Mian Li, Yuwei Zhao, Longtao Ma, Binbin Dong, Qing Huang, Jun Fan, Chunyi Zhi, Enhanced Redox Kinetics and Duration of Aqueous I2/I− Conversion Chemistry by MXene Confinement, Adv. Mater., 2021, DOI:10.1002/adma.202006897

Source of information: Energy scholar

This information is from the Internet for academic exchanges. If there is any infringement, please contact us and delete it immediately