1. Article overview

The rapid development of artificial skin, flexible sensors and soft robots has put forward more requirements for conductive hydrogels, which should have more functions. However, the development of integrated conductive hydrogels that combine multi-functional sensing and self-powered properties is still a huge challenge.

In this paper, a MXene-cellulose nanocrystal (CNC)-tamarind (TG)-polyacrylamide (PAM) ion conductive hydrogel was developed through a simple manufacturing process.

(1) By using TG with ion cross-linking network and PAM with UV light-initiated cross-linking network, the unique double network structure in the composite hydrogel is assembled, which gives the hydrogel toughness (38.8KJ/m2) And high stretchability (2000% strain).

(2) Due to the introduction of MXene and free ions, the hydrogel also has high sensitivity (specification factor = 5.23, 248% strain), so it exhibits multi-functional sensing characteristics for pressure, strain, humidity and temperature. More importantly, the hydrogel is self-powered and can generate up to 164 mV of open circuit voltage from moisture in a short period of time (18s).

The hydrogel not only shows huge potential applications in artificial skin, flexible sensors and soft robots, but also contributes to the development of next-generation artificial intelligence.

Two, graphic guide

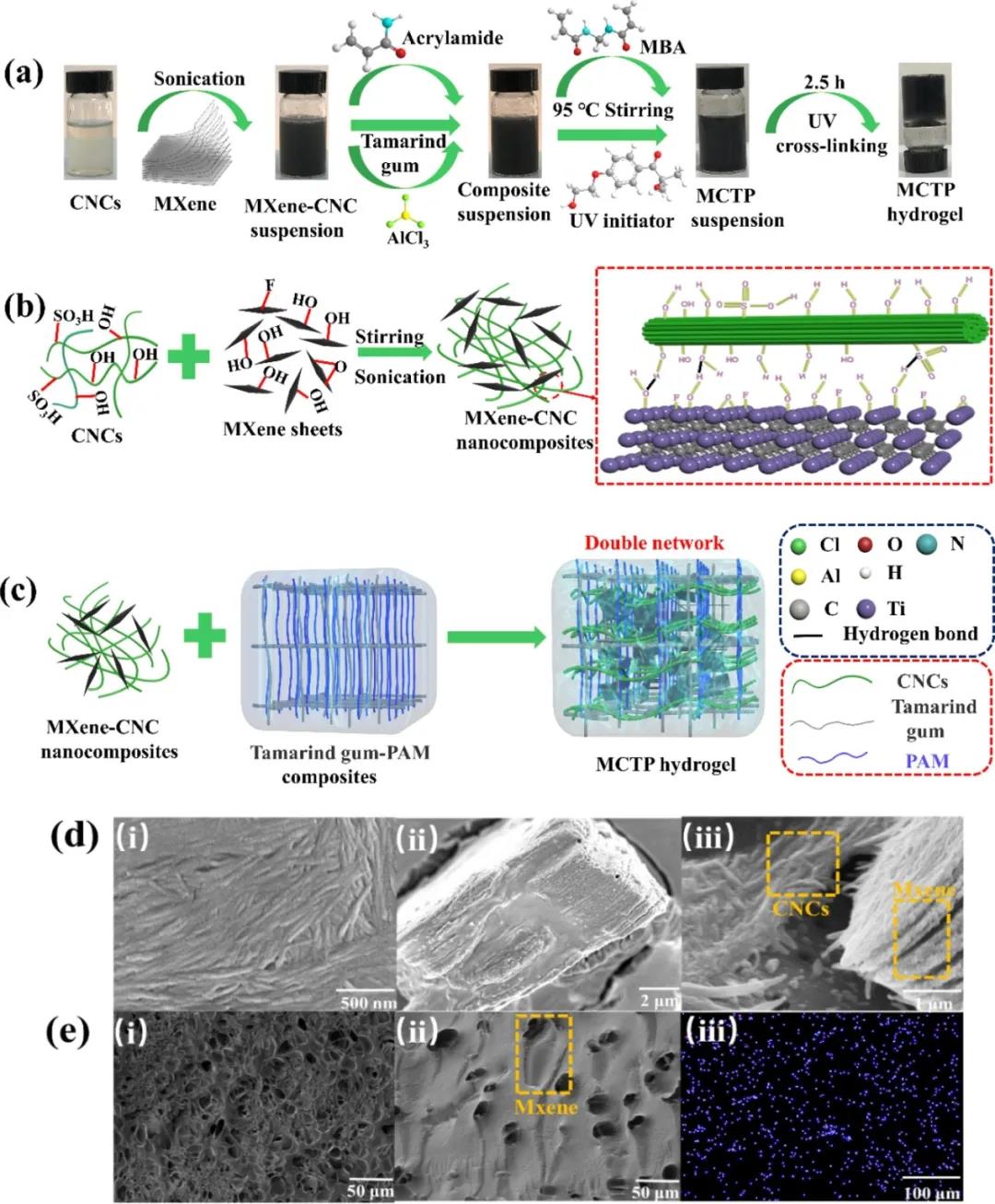

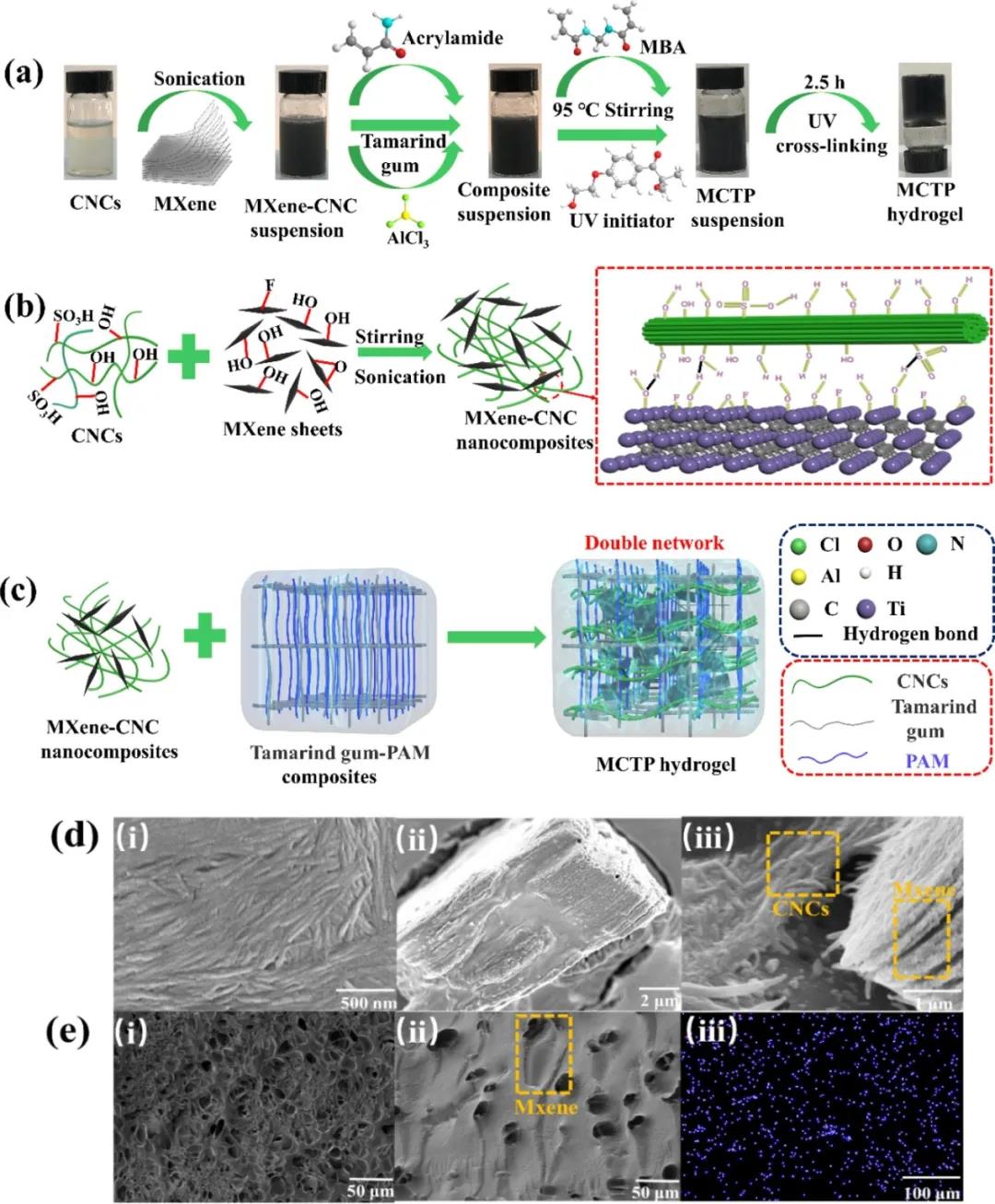

Figure 1. (a) Schematic diagram of the preparation process of MCTP hydrogel.

(B) Explain the possible interaction between CNC and MXene.

(C) illustrates the formation of double nets in MCTP hydrogel.

(D) SEM images of (i) CNCs, (ii) MXene sheets and (iii) MXene-CNC nanocomposites.

(E) (i) CTP, (ii) SEM images of cross-sections of MCTP hydrogels, and (iii) mapping images of titanium in MCTP hydrogels.

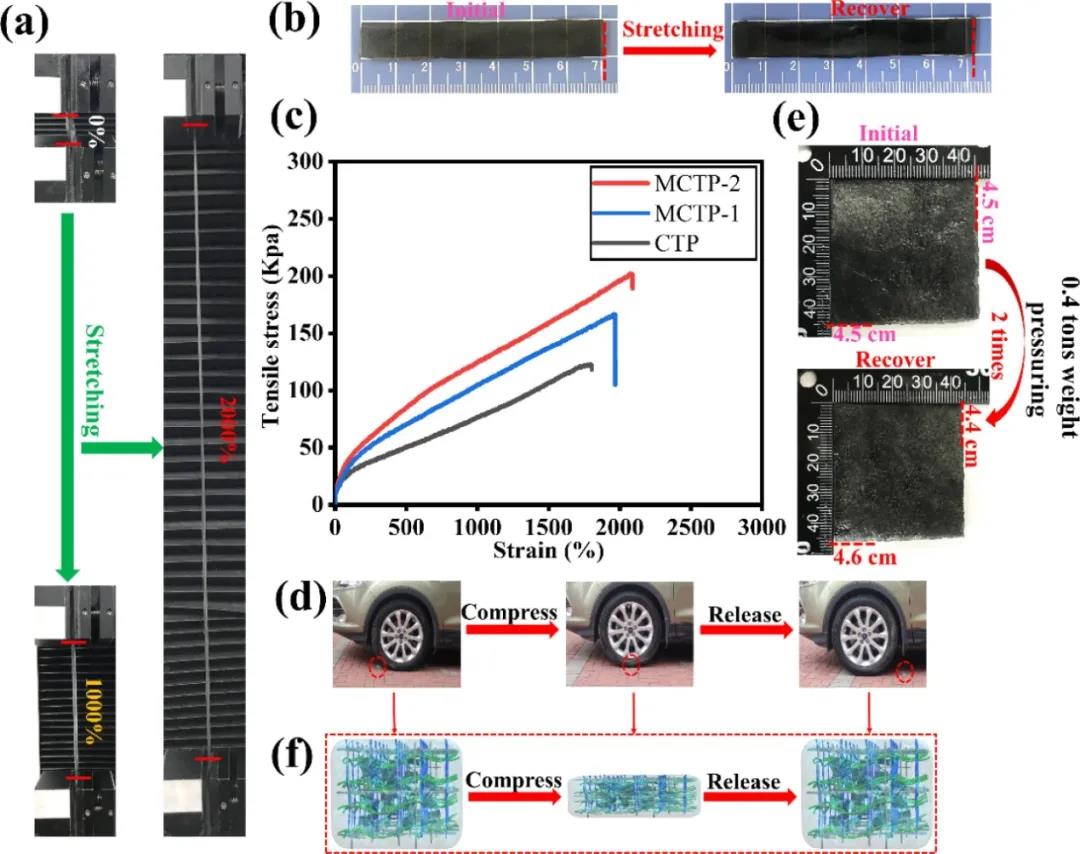

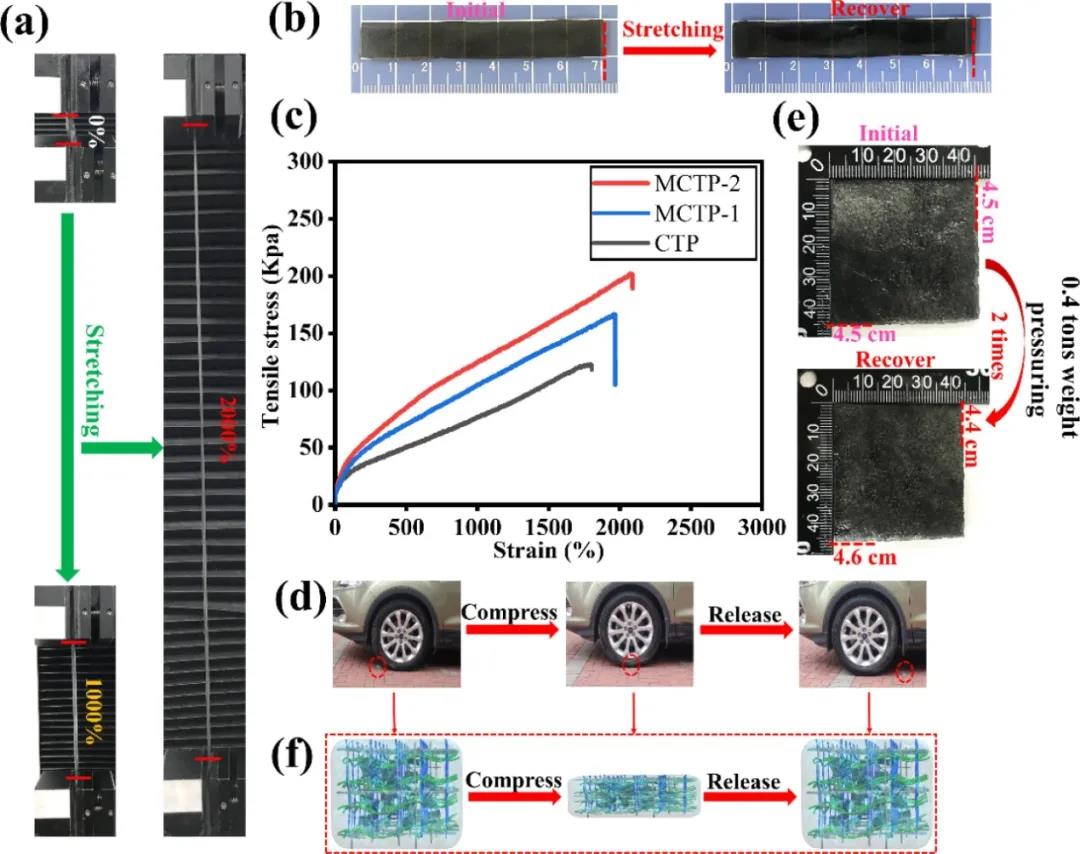

Figure 2. Mechanical properties of MCTP hydrogel.

(A) Photograph of MCTP hydrogel under stretching.

(B) Photos of MCTP hydrogel before and after stretching.

(C) Tensile stress-strain curves of MCTP hydrogels with different MXene content.

(D) Photograph of a 1.6-ton truck rolled MCTP hydrogel.

(E) The photos before and after the 0.4 ton single wheel was compressed twice.

(F) Schematic diagram of MCTP hydrogel under compression.

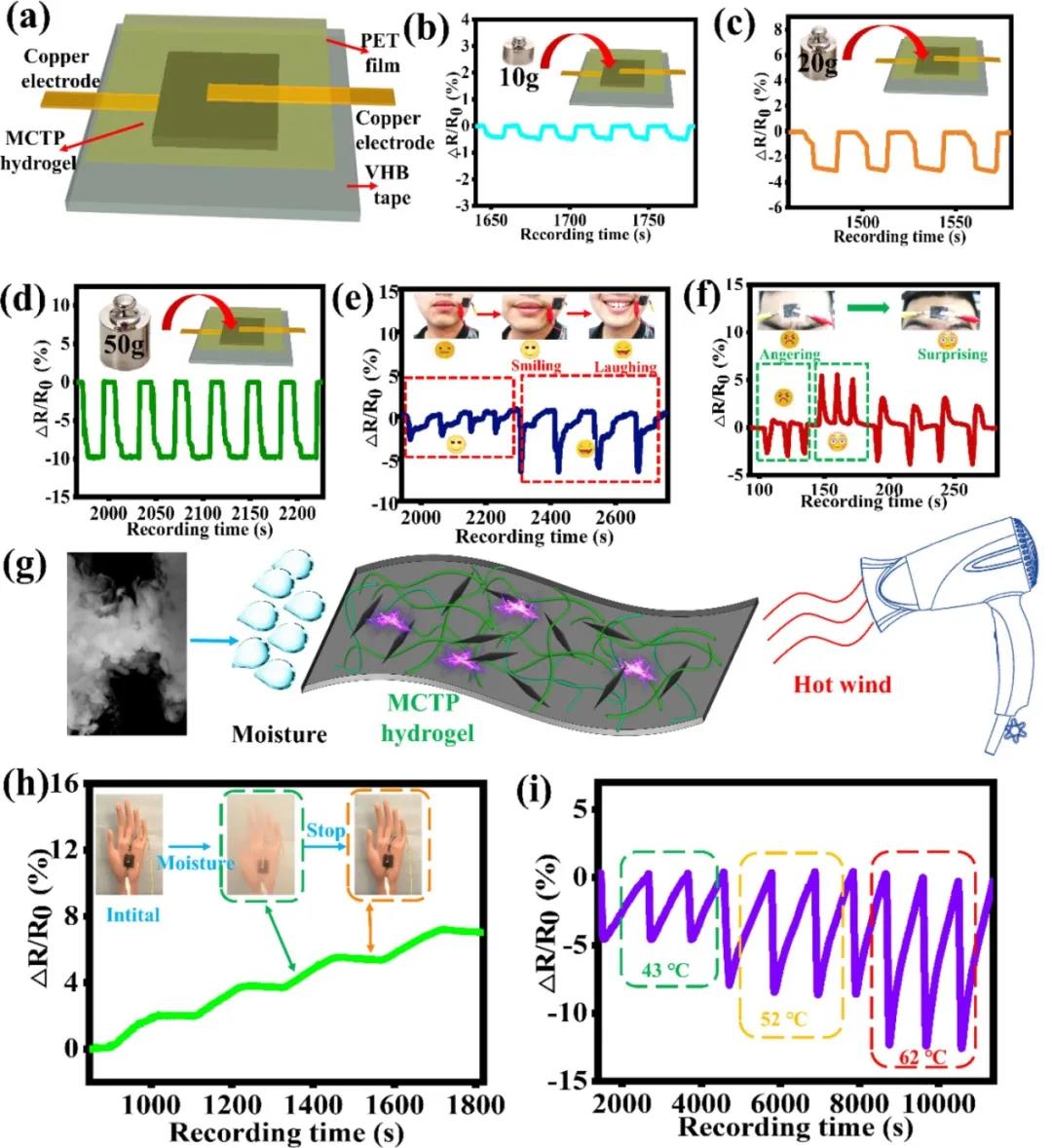

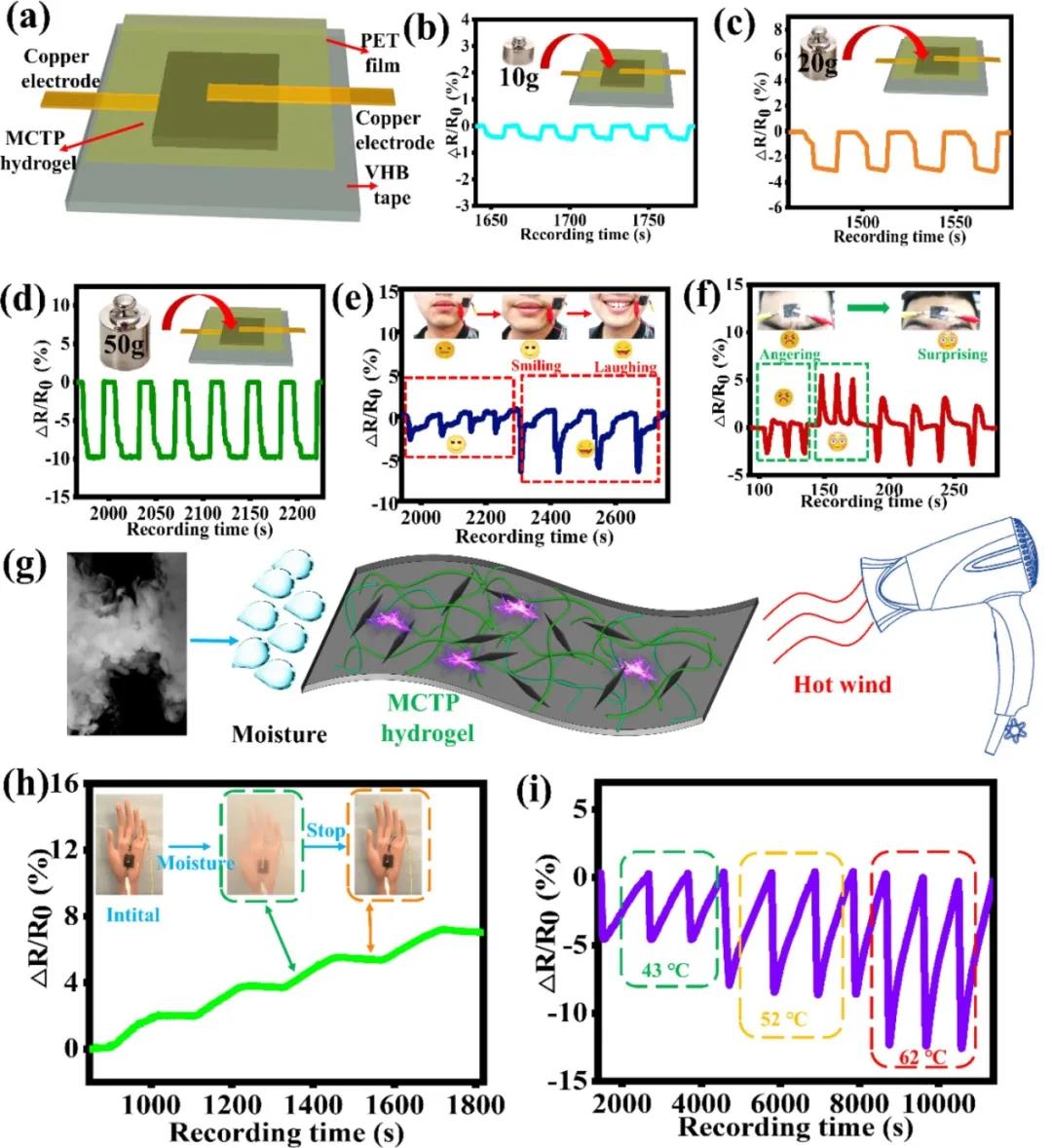

Figure 3. Various sensing properties of MCTP hydrogel-based sensors.

(A) The configuration of MCTP hydrogel based sensor.

(B-d) The resistance changes of MCTP hydrogel-based sensors weighing 10, 20, and 50 g respectively on the surface.

(E-f) Resistance change of MCTP hydrogel based sensor based on facial expression.

(G) The illustration shows the humidity and temperature of the MCTP hydrogel.

In response to (h) humidity and (i) temperature, the resistance of the MCTP hydrogel-based sensor changes.

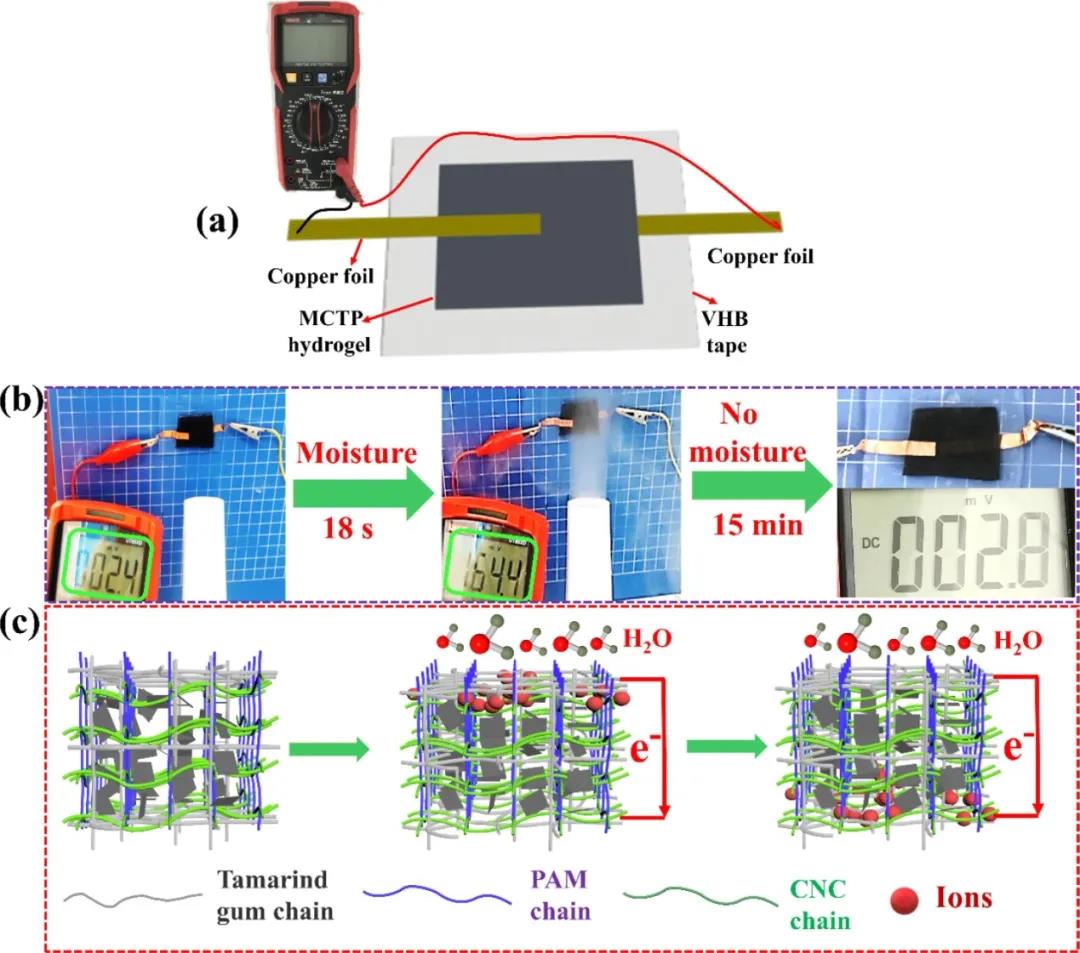

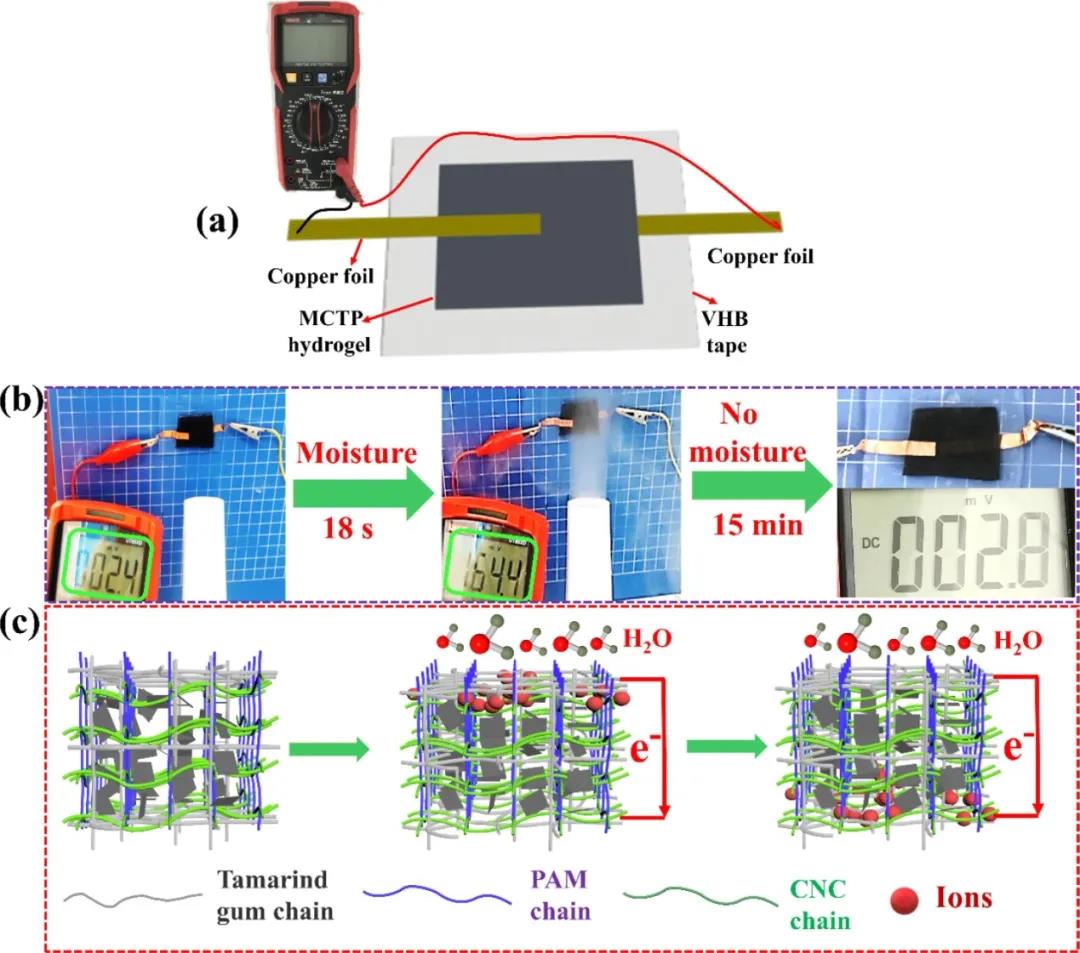

Figure 4. (a) Configuration of MCTP hydrogel-based moisture generator.

(B) Illustrate the power generation process of water flow.

(C) Schematic diagram of the mechanism of MCTP hydrogel generating electricity from moisture.

3. Thesis information

Tough and super-stretchable conductive double network hydrogels with multiple sensations and moisture-electric generation

Chemical Engineering Journal (IF=10.652)

Pub Date: 2021-01-29

DOI: 10.1016/j.cej.2021.128726

Peng He; Runsheng Guo; Kui Hu; Kai Liu*; Shan Lin; Hui Wu; Liulian Huang; Lihui Chen; Yonghao Ni

College of Materials Engineering, Fujian Agriculture and Forestry University, Fuzhou City, Fujian Province 350002, China