The structured colored colloidal sol of perovskite nanosheets was synthesized and fixed in the polymer hydrogel film by in-situ photopolymerization, thereby producing a new type of mechanically discolored material. Visible absorption spectroscopy, polarized optical microscopy and small-angle X-ray scattering show that the nanosheets are arranged parallel to the surface of the film with a periodic distance of up to 300 nm, which makes the structural color adjustable in the full color range. Recently, the structured color gel invented by the team of Professor Nobuyoshi Miyamoto of Fukuoka Institute of Technology showed a reversible mechanically induced color response. The response detected a weak stress of 1 kPa, a fast response time of less than 1 ms, and a high mechanical toughness (compression The fracture stress is as high as 3 MPa). These excellent properties are suitable for mechanical sensor and display applications. The related paper was published in "Germany Applied Chemistry" with the title of Perovskite Nanosheet Hydrogels with Mechanochromic Structural Color.

The structured colored colloidal sol of perovskite nanosheets was synthesized and fixed in the polymer hydrogel film by in-situ photopolymerization, thereby producing a new type of mechanically discolored material. Visible absorption spectroscopy, polarized optical microscopy and small-angle X-ray scattering show that the nanosheets are arranged parallel to the surface of the film with a periodic distance of up to 300 nm, which makes the structural color adjustable in the full color range. Recently, the structured color gel invented by the team of Professor Nobuyoshi Miyamoto of Fukuoka Institute of Technology showed a reversible mechanically induced color response. The response detected a weak stress of 1 kPa, a fast response time of less than 1 ms, and a high mechanical toughness (compression The fracture stress is as high as 3 MPa). These excellent properties are suitable for mechanical sensor and display applications. The related paper was published in "Germany Applied Chemistry" with the title of Perovskite Nanosheet Hydrogels with Mechanochromic Structural Color.

【Graphic Analysis】

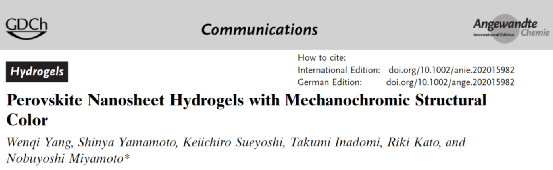

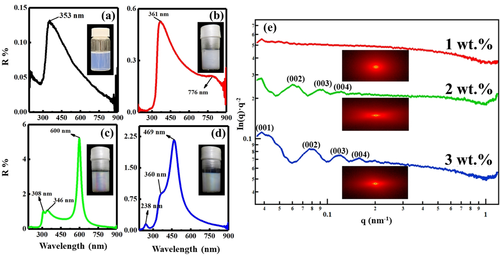

The perovskite nanosheet colloid shows a bright structure color that can be adjusted by changing the concentration of the nanosheet. The 3 wt% (Figure 1 d) and 2 wt% (Figure 1 c) nanosheet colloids show a structural color with pearly luster, while the 1 wt% (Figure 1 b) colloid is colorless. In the ultraviolet-visible (UV/Vis) reflection spectrum, the 3 wt% colloid (Figure 1d) shows the maximum reflection wavelength λmax of 469 nm. The strong absorption below 360 nm is due to the band gap absorption of the semiconductor perovskite nanosheets, which has been observed, and the band gap absorption is also observed in the unstructured dilute colloid (0.1 wt%) (Figure 1 a).

Figure 1 Characterization of the structure and color colloidal sol of liquid crystal perovskite nanosheets.

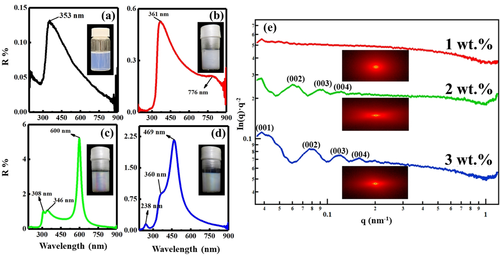

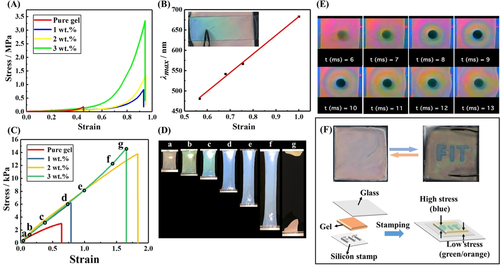

Although the above-mentioned structural color is highly dependent on various factors, the nanosheet colloid with structural color has been successfully fixed as a composite gel. During the synthesis of the hydrogel, the structural color and interlayer distance between the nanosheets changed, as revealed by the UV/Vis spectrum (Figure 2A). In the cross-sectional image (Figure 2B), when the angle between the crossed polarizer and the gel surface is 45°, a strong interference color due to the birefringence of the aligned LC nanosheets is observed, and the image varies with the angle The change of darkening to 0° from the scanning electron microscope (SEM) observations of the surface and cross-section (Figure 2D) also confirmed the above structure. In the surface image (Figure 2E and F), nanosheets of a few microns are observed. In the cross-sectional view, many streaks caused by nanosheets stacked parallel to the direction of the gel surface were observed (Figure 2 G and H). In contrast, the gel without nanosheets only shows a three-dimensional network structure with pores (Figure 2I).

Figure 2 Characterization of a structured color nanosheet/PNIPA composite hydrogel with 3% nanosheets.

In addition, the compressive strength of the composite gel is greater than that of the pure PNIPAm gel (Figure 3A). Figure 3B shows the relationship between the compressive strain of the structural color gel and λmax. As the strain increases, the color of the structure changes from orange (λmax = 683 nm) to blue (λmax = 481 nm). In the tensile deformation, the color change is more sensitive than the compression deformation (Figure 3D). When responding quickly, place 10 micrograms of substance 5 cm above the gel, causing it to fall and hit the gel; observe the process with a high-speed camera. When the substance hits the gel, the color of the contact point changes significantly (Figure 3 E). In order to demonstrate the performance of structural color glue as a seal, we made a silicone rubber stamp with the letters "FIT" and placed it under the structural color glue covered with a glass plate (Figure 3F).

Figure 3 Mechanical discoloration of nanosheet/PNIPAm composite hydrogel.

【to sum up】

The team obtained the first structural color colloidal sol of perovskite nanosheets and successfully fixed it as a hydrogel. The hydrogel has a uniform macrostructure color that can be adjusted by the concentration of nanosheets and has a strong structure due to the enhancement of nanosheets. The high mechanical toughness. In addition, the structural color gel of the present invention exhibits excellent mechanically induced color behavior, has rapid response and high sensitivity, and will be used as an intelligent mechanical sensor and display. The high design and various functions of perovskite nanosheets will further lead to future multifunctional structural color materials.

Reference: doi.org/10.1002/anie.202015982