Hydrogels are similar to biological tissues in that they are a three-dimensional polymer network containing a lot of water. Hydrogel has good biocompatibility, so it has great application prospects in the fields of biological tissue engineering such as artificial soft tissues and artificial organs. Although it is currently possible to introduce a sacrificial bond energy dissipation mechanism to make the toughness of hydrogels comparable to or even surpass that of biological tissues, the preparation of hydrogels that are similar to load-bearing soft tissues with excellent properties such as self-repair, high toughness, fatigue resistance, etc. It is still a big challenge in the field of new materials. The reason is that the current synthetic hydrogel structure is relatively simple, and the fatigue performance is only determined by the molecular chain network, which is in sharp contrast with biological tissues that have multi-scale structures spanning multiple orders of magnitude that can cooperate to resist fatigue.

Earlier, the team of Professor Gong Jianping of Hokkaido University reported that the self-healing polyampholyte hydrogel (PA glue, Nat. Mater. 2013, 12 (10), 932–937) developed by the research group can achieve the fatigue threshold in the dual continuous phase separation network. It inhibits crack propagation and delays fatigue fracture, which is manifested as a special multi-stage fatigue resistance behavior (Proc. Natl. Acad. Sci. USA, 2020, 117: 7606-7612). Recently, Professor Gong Jianping’s team published a paper entitled Effect of mesoscale phase contrast on fatigue-delaying behavior of self-healing hydrogels (DOI: 10.1126/sciadv.abe8210) in Science Advances, which further elaborated on the number of PA glues. The role of each level of the scale structure in the multi-level fatigue resistance model and reveals the contribution of molecular chain topological entanglement to the fatigue threshold.

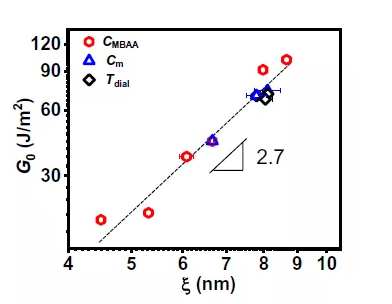

Figure 1. The multi-scale structure in the flexible self-healing PA glue contains ~0.1nm reversible ionic bonds, ~1nm transient network (black dotted circle), ~10nm permanent polymer network (red circle) and ~100nm bicontinuous Phase separation network. The mesh size ξ of the permanent polymer network of the PA glue depends on the effective crosslinking density υe (υe is jointly determined by chemical crosslinking and topological entanglement). ξ can be effectively controlled by the chemical crosslinking agent content CMBAA and the total monomer moles Cm during synthesis. The characteristic scale d0 and phase separation contrast Δρ of the dual continuous phase separation network depend on ξ and the dialysis conditions of as-prepared gels (here, the dialysis temperature Tdial is mainly studied).

In this work, the chemical cross-linking density in the hydrogel is adjusted by systematically changing the content of the cross-linking agent CMBAA added during the preparation, and the topological entanglement concentration Ce is adjusted by changing the total monomer concentration Cm, because the topological entanglement concentration Ce and the monomer The concentration has a scale relationship Ce ~ Cm2.3. The PA glue system is very special: when the counterion is removed by dialysis, the positive and negative charges on the molecular chain attract each other to form a large number of ionic bonds, which causes the PA glue molecular chain after dialysis equilibrium to shrink into a curly spherical conformation, and ξ ≅ bNe1/ 3. Among them, ξ is the grid size composed of effective molecular chains, b is the repeating unit size, and Ne is the effective molecular chain polymerization degree. Furthermore, the volume fraction Φ occupied by dialysis-balanced PA glue polymer chains is Φ ≅ (b3Ne)/ξ 3 ~ (b3Ne)/(bNe1/3)3 ~ Ne0, which shows that the volume fraction of polymer chains does not It changes with the degree of polymerization of the effective chain. Therefore, the water content of the hydrogel prepared by researchers through different formulations or dialysis conditions is almost constant, which facilitates the analysis and comparison of the subsequent data.

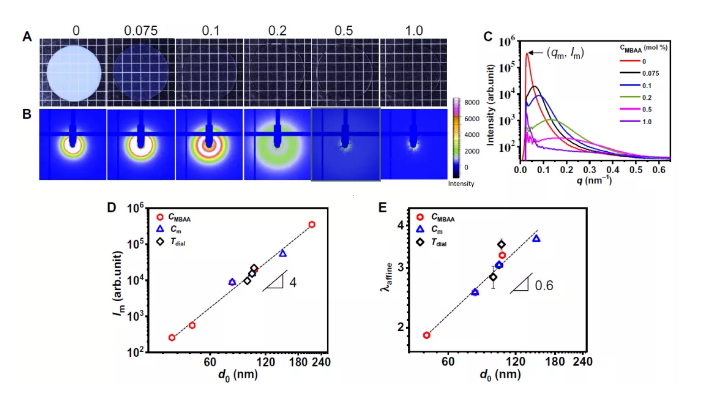

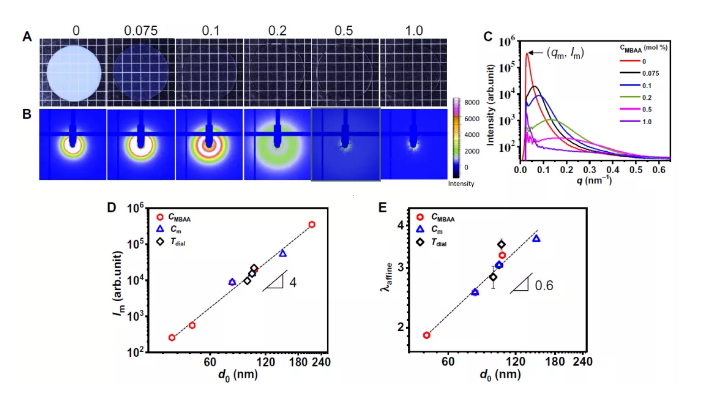

Figure 2. The phase separation structure of PA glue was successfully controlled through synthetic formula. (A) photos of PA glue with different crosslinking agent content (CMBAA mol%), (B) 2D small-angle X-ray scattering graph, and (C) 1D small-angle X-ray scattering integral curve. (D) The intrinsic relationship between the scattering intensity Im (proportional to the phase separation contrast Δρ2) of the three groups of different samples and the characteristic scale d0 of the bicontinuous phase separation network. (E) The relationship between the maximum affine deformation (λaffine) and the characteristic scale d0 of the bicontinuous phase separation network of three different samples under uniaxial stretching.

Researchers have successfully prepared PA glues with different effective molecular chain sizes by changing CMBAA and Cm, and the effective molecular chain size of PA glue can determine its phase separation structure (Macromolecules, 2020, 53(13): 5116-5126). Taking the samples of the CMBAA group as an example, it can be seen from Figures 2A-C that the more the amount of cross-linking added, the weaker the degree of phase separation of the PA glue. According to the X-ray scattering results and the difference in the mechanical behavior of the gel, the hydrogel with 0.1mol% CMBAA is divided into the strong phase separation group (Im>1k), and the hydrogel with CMBAA>0.1mol% is divided into the weak phase separation group ( Im<1k). Figure 2D shows that regardless of the strong phase separation or the weak phase separation hydrogel, although the preparation conditions are different, the scattering intensity Im (proportional to the phase separation contrast Δρ2) of the three sets of samples exists between the characteristic scale d0 of the bicontinuous phase separation network The intrinsic relationship Im~d04 shows that the relationship between phase separation contrast and feature size is inherent, and this inherent relationship should be the result of competition between phase separation and network elasticity. Through the online X-ray in-situ detection method, it is found that the relationship between the maximum affine deformation (λaffine) and the characteristic scale d0 of the bicontinuous phase separation network of three groups of different samples during uniaxial stretching is λaffine~d00.6. This relationship can be inferred that the mesoscopic phase separation network in PA glue can be equivalent to a self-evasive walking chain.

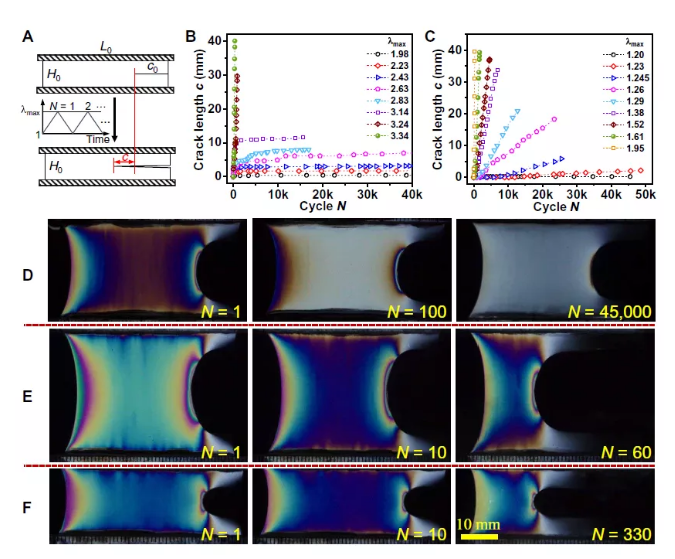

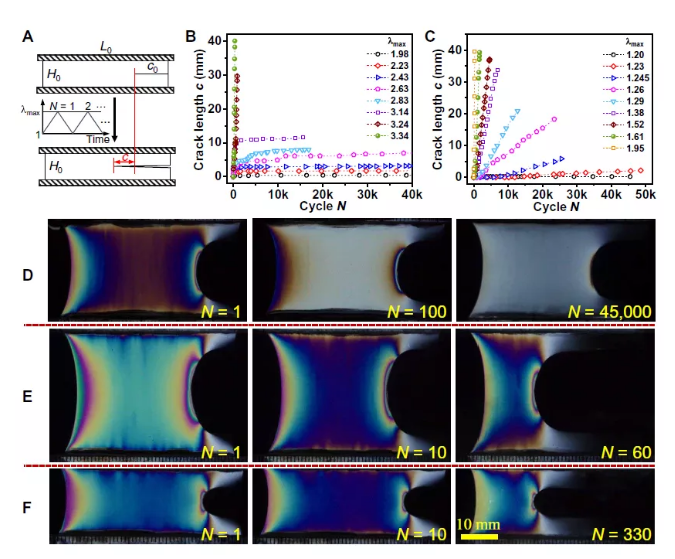

Figure 3. Crack growth behavior of PA glue with strong phase separation and weak phase separation. (A) Schematic diagram of pure shear geometry and fatigue loading conditions, (B) PA glue with strong phase separation evolves with cyclic loading, (C) PA glue with weak phase separation evolves with cyclic loading, (D) strong phase When the separated PA glue is λmax<λtran, the result of circular polarization, (E) when the PA glue with strong phase separation is λmax>λtran, the result of circular polarization, (F)) when the PA glue with weak phase separation is at a smaller λmax, Circular polarization results.

The fatigue test results found that only the hydrogel with strong phase separation exists above the fatigue threshold, and the crack growth is inhibited: when loading λ0 <λmax<λtran, the crack gradually expands from the initial rapid expansion and is difficult to continue to grow, at λmax> λtran, the crack propagates rapidly until the sample is completely broken, λ0 is the maximum stretching ratio corresponding to the fatigue threshold, and λtran is defined as the stretching ratio of the transition from slow to fast crack propagation (Figure 3B). The cracks of the weak phase separation hydrogel grow linearly with the number of cycles (Figure 3C). The birefringent structure of the circularly polarized light test shows that the strong phase separation of the hydrogel is λmax<λtran, and the stress concentration at the crack tip gradually decreases with the increase of the number of cycles, and is almost eliminated after tens of thousands of cycles (Figure 3D). For the hydrogel with strong phase separation at λmax>λtran, and for the hydrogel with weak phase separation under very small strain, there is always a butterfly-shaped stress concentration zone at the crack tip (Figure 3E-F). This also explains Figure 3B and Figure 3C.

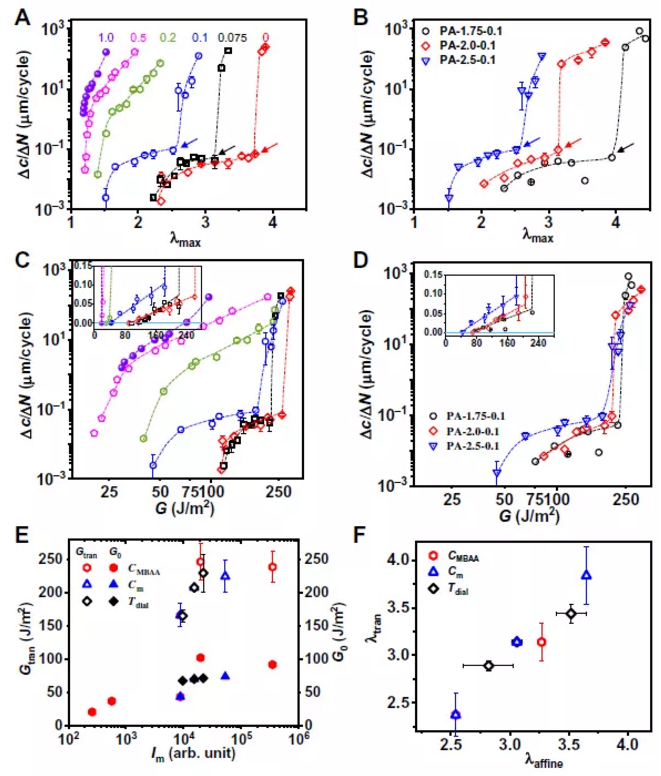

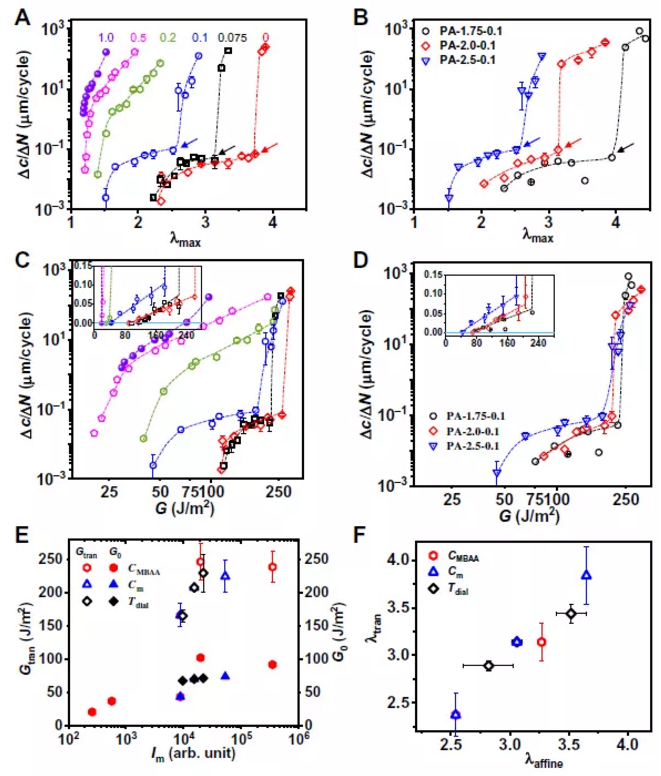

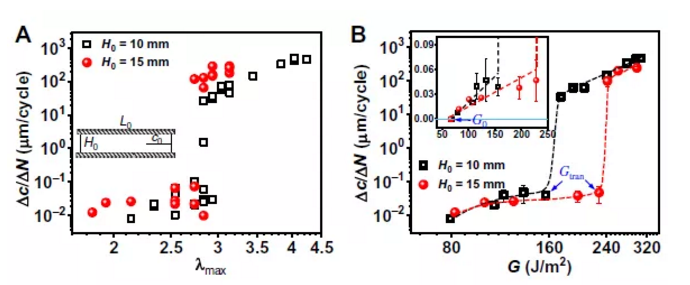

Figure 4. Hydrogel fatigue results with different degrees of phase separation. (A) The crack growth rate of different CMBAA hydrogels (Δc/ΔN) varies with λmax, (B) The Δc/ΔN of different Cm hydrogels varies with λmax, (C) The crack growth rate of different CMBAA hydrogels ( Δc/ΔN) changes with the energy release rate G, (D) Δc/ΔN of different Cm hydrogels changes with the energy release rate G, (E) the energy release rate (Gtran) at the transition point where the crack grows from slow to fast growth (Gtran) and The fatigue threshold G0 is plotted against Im, and (F) λtran is plotted against λaffine.

Therefore, only the hydrogel with strong phase separation has a multi-stage fatigue resistance mode, that is, above the fatigue threshold, the crack growth rate is very slow, until a transition point (λtran, Gtran), the crack growth rate has a jump (Figure 4A, C). There is only a single anti-fatigue mode similar to a simple network in the weak phase separation, that is, above the fatigue threshold G0, the crack growth rate increases rapidly with λmax or G (Figure 4B, D). From the graph of Gtran and G0 versus Im (Figure 4E), only when Im>10 k arb.unit, PA glue has multi-level anti-fatigue performance values G0 and Gtran; when Im<10 k arb.unit, Only G0 exists in PA glue. Figure 4F shows that the larger the λaffine, the larger the λtran, and the effective strategy for enhancing the anti-fatigue of PA glue is to increase d0 and Im through formulation improvement.

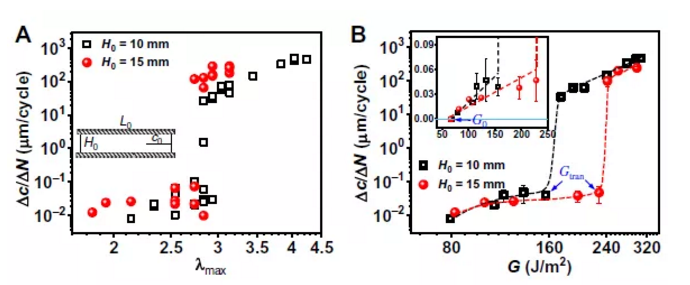

Figure 5. The effect of sample geometry on the fatigue performance of strong phase separation PA glue. (A) The crack growth rate (Δc/ΔN) of samples with different initial heights (H0) varies with the energy release rate G, (B) The Δc/ΔN of samples with different initial heights (H0) varies with the energy release rate G. The figure shows that G0 and λtran have weak geometrical size dependence.

Due to the existence of multi-level fatigue resistance modes, there are many parameters related to fatigue performance in PA glue, such as λ0, G0, λtran, Gtran, etc. Figure 5 verifies that G0 and λtran are characteristic parameters of this crack tip strong passivation system (Weakly related to sample geometry). Because the transition point of the crack from slow to fast growth is related to whether there is damage to the hard phase structure in the gel body, there is no damage, the hard phase structure is oriented to resist crack growth, the crack tip is blunt, and the stress concentration is continuously weakened; there is damage , The soft phase is not enough to resist crack growth, the strong stress concentration at the crack tip cannot be relieved, and the crack grows rapidly. The parameter that determines whether there is damage is λaffine. Figure 4F shows that λtran and λaffine are correlated. Please see the original text for detailed analysis.

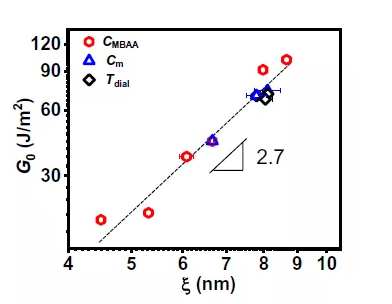

Figure 6. The fatigue threshold G0 of PA glue is plotted against ξ. ξ is the effective molecular chain mesh size determined by chemical cross-linking and topological entanglement.

It can be seen from Figure 6 that the contribution of topological entanglement to G0 is equivalent to chemical crosslinking. The most direct evidence is that G0 and Gtran are also present in pure physical PA glue (completely free of chemical cross-linking). At the same time, it can be deduced from the Lake-thomas equation that if G0 is completely derived from the effective molecular chain breakage of the permanently cross-linked network structure, the scale relationship between G0 and ξ should be G0~ξ. However, the relationship shown in this figure is G0~ξ 2.7, indicating that dynamic ionic bonds also contribute to G0. There are two evidences to prove: 1. By comparing the fatigue results of PA glue after dialysis (containing a lot of ionic bonds) and PA glue without dialysis (the amount of internal ionic bonds is negligible), it is found that the G0 of the PA glue after dialysis is greater than No dialysis (in order to eliminate the influence of phase separation, this result uses PA glue with no phase separation structure, and also excludes the influence of polymer chain volume fraction. The figure is in the article SI); 2. The PA glue system is based According to the calculation of the structural model (soft matter, 2021. https://doi.org/10.1039/D1SM00110H), the characteristic time (~10 ms) of the healing of the ionic bond is an order of magnitude shorter than the destruction time, which is significantly faster than the observation time size (Loading rate 1s-1).

This article has a deeper understanding of the anti-fatigue mechanism of self-healing hydrogels with multi-size structures, especially the intrinsic relationship between various hierarchical structures and fatigue resistance. It is also for the development of self-healing, high tensile, high toughness, and Hydrogels that are resistant to fatigue and other properties suggest potential strategies. The synchrotron radiation small-angle X-ray in-situ detection of this work was completed at the Shanghai synchrotron radiation source. The online in-situ temperature and humidity control reciprocating stretching device used was made by Hefei Puliang Technology Co., Ltd. (http://www.pl-tech. cn/) Cooperative research and development.

Paper link:

DOI: 10.1126/sciadv.abe8210