background

Lithium-ion battery (LiBS) has the advantages of high energy/power density, long cycle life, low self-discharge performance, etc., and is one of the most potential energy storage devices among various rechargeable batteries. However, the current LIBS cannot meet the ever-increasing requirements for safety and rapid charging and discharging. As one of the main components of LIBS, the diaphragm plays a vital role in the safety and rate performance of LIBS. Among the many diaphragms, composite diaphragms have been extensively studied in terms of improving their thermal stability, mechanical strength, electrolyte absorption and ion conductivity. This article reviews the challenges and limitations of LIBS commercial diaphragms, and systematically reviews the latest research progress of composite diaphragms in order to achieve a safe and efficient LIBS. Covers various combination types of composite diaphragms, including blended type, layered type, core-shell type and grafted type. In addition, models and simulations based on different types of composite diaphragms are also discussed to understand the robust performance mechanism of composite diaphragms. Finally, the direction and prospects for the further development of composite diaphragms are prospected to improve the safety and rate capability of LIBS.

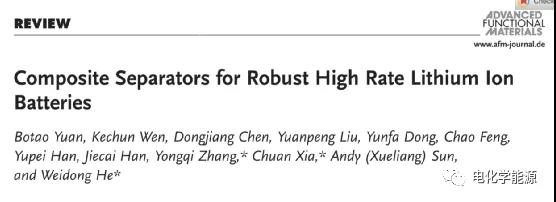

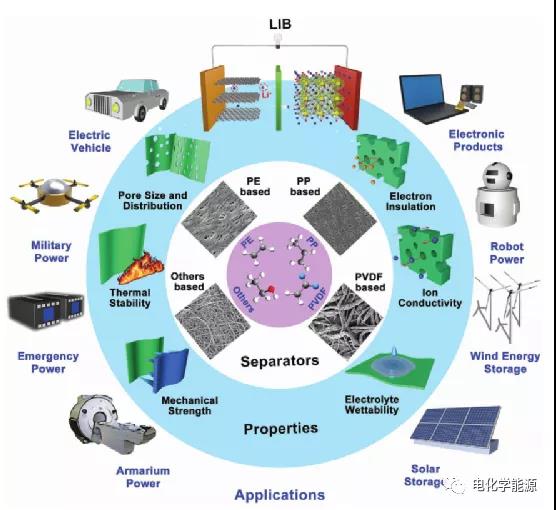

Figure 1. Diaphragm and its application in lithium-ion batteries: including the microstructure of PE, PP, PVDF, etc.

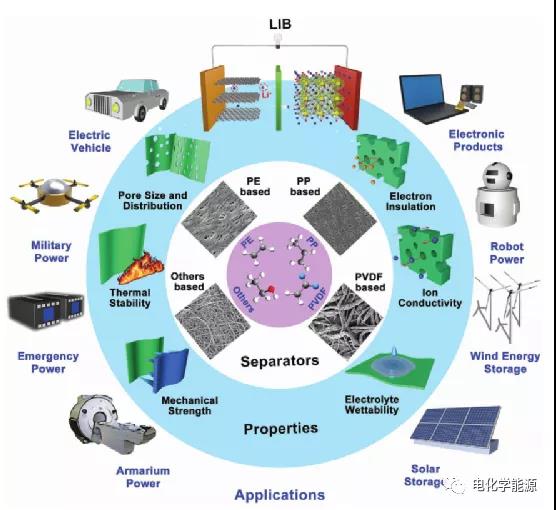

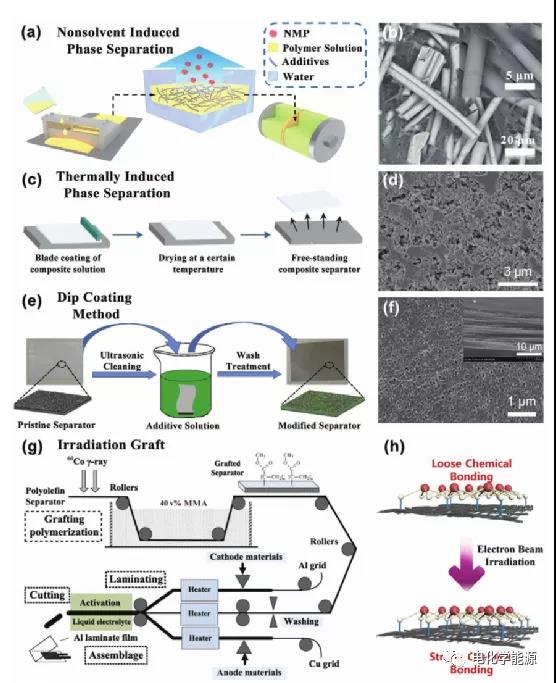

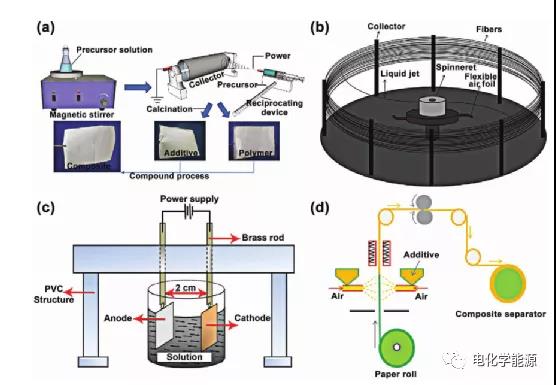

Figure 2. Diaphragm manufacturing method.

a, b) The process steps of the non-solvent induced phase separation method to prepare the diaphragm and the scanning electron microscope (SEM) micrographs of the corresponding composite diaphragm.

c, d) Thermally induced phase separation method. Reproduced with permission.

e, f) Dip coating method. Reproduced with permission.

g) Irradiation graft copolymerization technology.

h) Electron beam irradiation process.

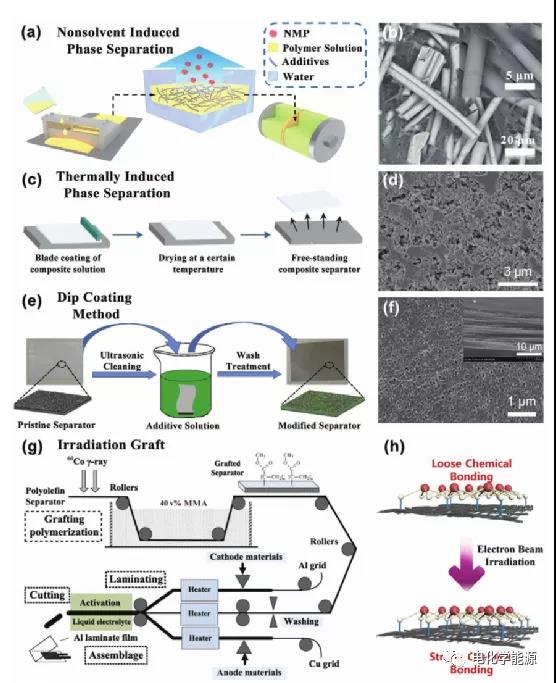

Figure 3. Diaphragm preparation method.

a) Schematic diagram of the process steps for preparing the diaphragm by electrospinning.

b) Centrifugal spinning method.

c) Electrophoretic deposition method.

d) Wet compress method.

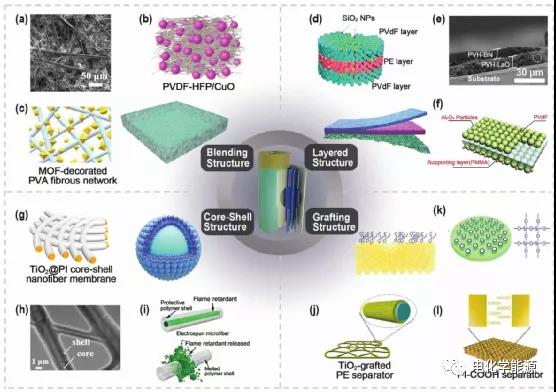

Figure 4. Modification method of composite diaphragm.

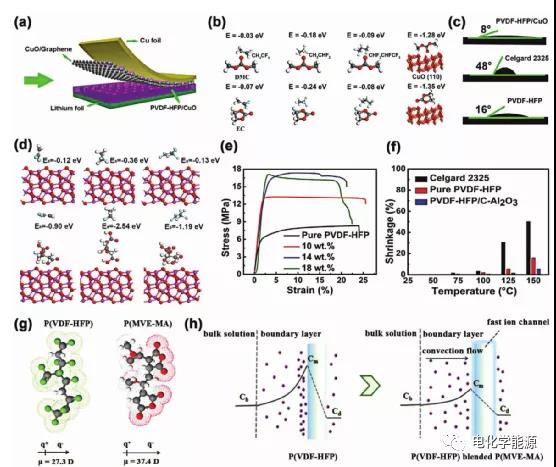

Figure 5. Diaphragm modification and mechanism of action.

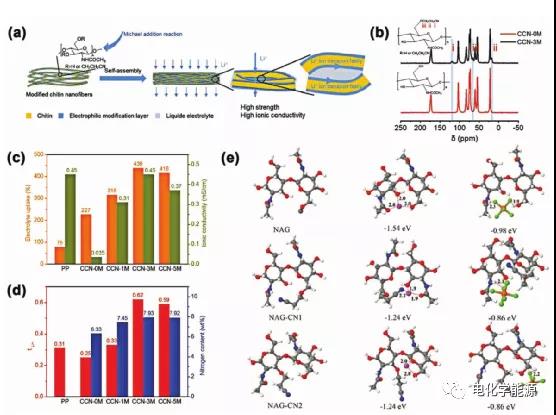

Figure 6. Diaphragm modification and mechanism of action.

to sum up

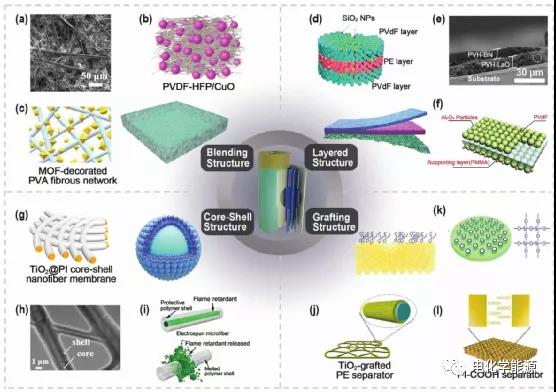

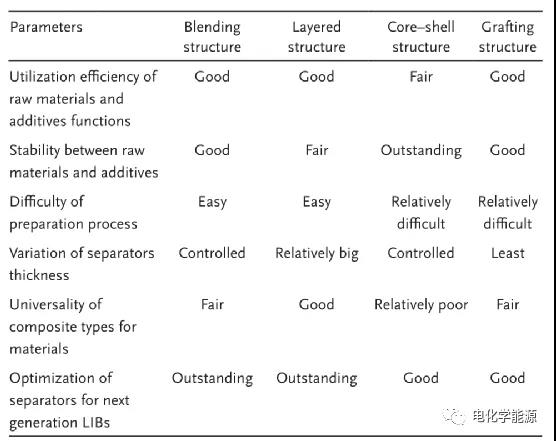

Among many diaphragms, composite diaphragms have received widespread attention due to improvements in thermal stability, mechanical strength, electrolyte absorption, and surface properties. The performance of the composite diaphragm is closely related to the safety, stability and rate discharge capability of LIBS. In this paper, starting from the composite type of composite diaphragm, the latest research progress of safe and efficient composite diaphragm is reviewed. According to the type of composite material, it can be divided into four categories, including blended structure, layered structure, core-shell structure and grafted structure. In addition, the latest progress of these types of composite diaphragms in improving core performance and realizing safe and efficient LIBS is also discussed in detail.

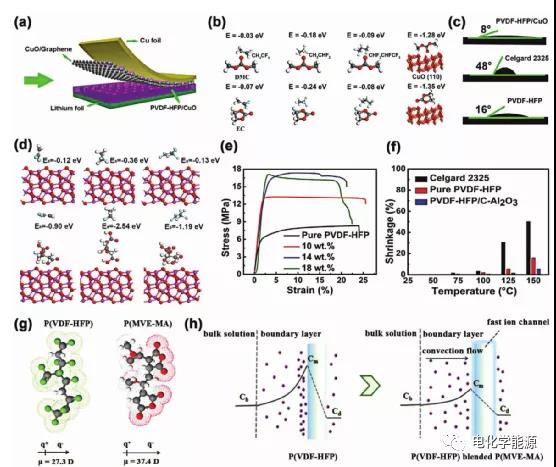

1. For the type of blend structure, based on commercial separators, based on PVDF and its copolymers and composite separators based on other polymer materials. Although commercial polyolefin membranes have excellent mechanical strength, pore size and good chemical stability, their poor wettability and thermal stability have severely restricted the development of LIBS. When the internal temperature of the battery exceeds 120°C, the commercial separator will severely shrink, causing short circuit of the positive and negative electrodes, thermal runaway, and even the battery burns and explodes. In addition, due to the excessive deposition of lithium ions on the electrodes, lithium dendrites will be generated and penetrate the separator, resulting in capacity degradation and safety hazards of the lithium ion battery. Incorporating ceramic particles or high melting point polymers can effectively improve the thermal stability and wettability of industrial separators. In addition, polyvinylidene fluoride (PVDF) and its copolymers have received widespread attention due to their inherent good wettability, but their poor mechanical properties need to be improved by additives to avoid safety issues. It has also studied the use of other polymer materials as raw materials to form a hybrid diaphragm to achieve the optimization of the dual performance of raw materials and additives. For the type of mixed structure, adjusting the ratio of the amount of raw materials and additives has become a key way to control the performance of the composite diaphragm.

2. Composite diaphragm with layered structure. Commercial polyolefin membranes are coated with a ceramic layer or polymer chain layer to improve their thermal stability and wettability. Other polymers, such as PVDF-HFP, PI and PET, are used as substrates due to their inherent excellent properties. On the basis of the substrate support, the characteristics of the additive layer can be highlighted in the layered composite film. Compared with the blend structure type, the laminated structure of the composite diaphragm has unique advantages. The added layer can be multifunctional. The conductive layer as an additive can be laminated to suppress the growth of lithium dendrites and further improve the safety of lithium ion batteries. In addition, the difference is that each layer of the layered separator has a different function. For example, adding additives to the upper layer can improve mechanical properties, and the lower layer can improve thermal stability. The composite diaphragm can meet the requirements of high-safety and high-efficiency LIBS.

3. Composite diaphragm with core-shell structure. Polyvinylidene fluoride (PVDF) and its copolymers, as long-chain macromolecular polymers, are usually designed as a shell structure that wraps nanoparticles or short-chain polymer molecules. The main role of nanoparticles or short-chain polymers in core-shell composite membranes is to improve mechanical strength, thermal stability and flame retardancy. Other polymers, such as cellulose and polyimide, can also be used as the shell layer to improve the performance of the composite diaphragm, and then add the core material. The main feature of the core-shell structure is to maintain the stability of the core and avoid the dispersion or agglomeration of additives when lithium ions pass through the diaphragm. Therefore, the core-shell structure of the composite separator can greatly improve the structural stability of the lithium-ion battery under high current density, thereby increasing the rate capacity.

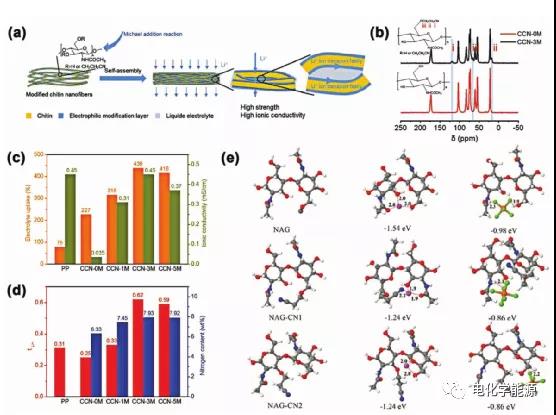

4. Composite diaphragm with graft structure. Including membrane materials and other polymer materials (PVDF, PI and chitin) grafted structure. The surface graft modification greatly enhances the thermal stability and wettability of industrial separators. In addition, composite diaphragms based on other polymers have also been developed to improve the overall performance of composite diaphragms by grafting particles or functional groups. Compared with other types of composite materials, the main feature of this grafted structure is to graft additives or functional groups on the surface of the membrane without sacrificing the porous structure of the membrane and increasing the thickness of the membrane.

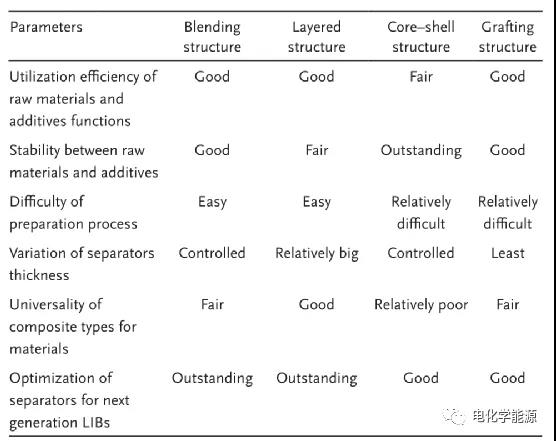

Table The advantages and disadvantages of the four types of composite diaphragms.

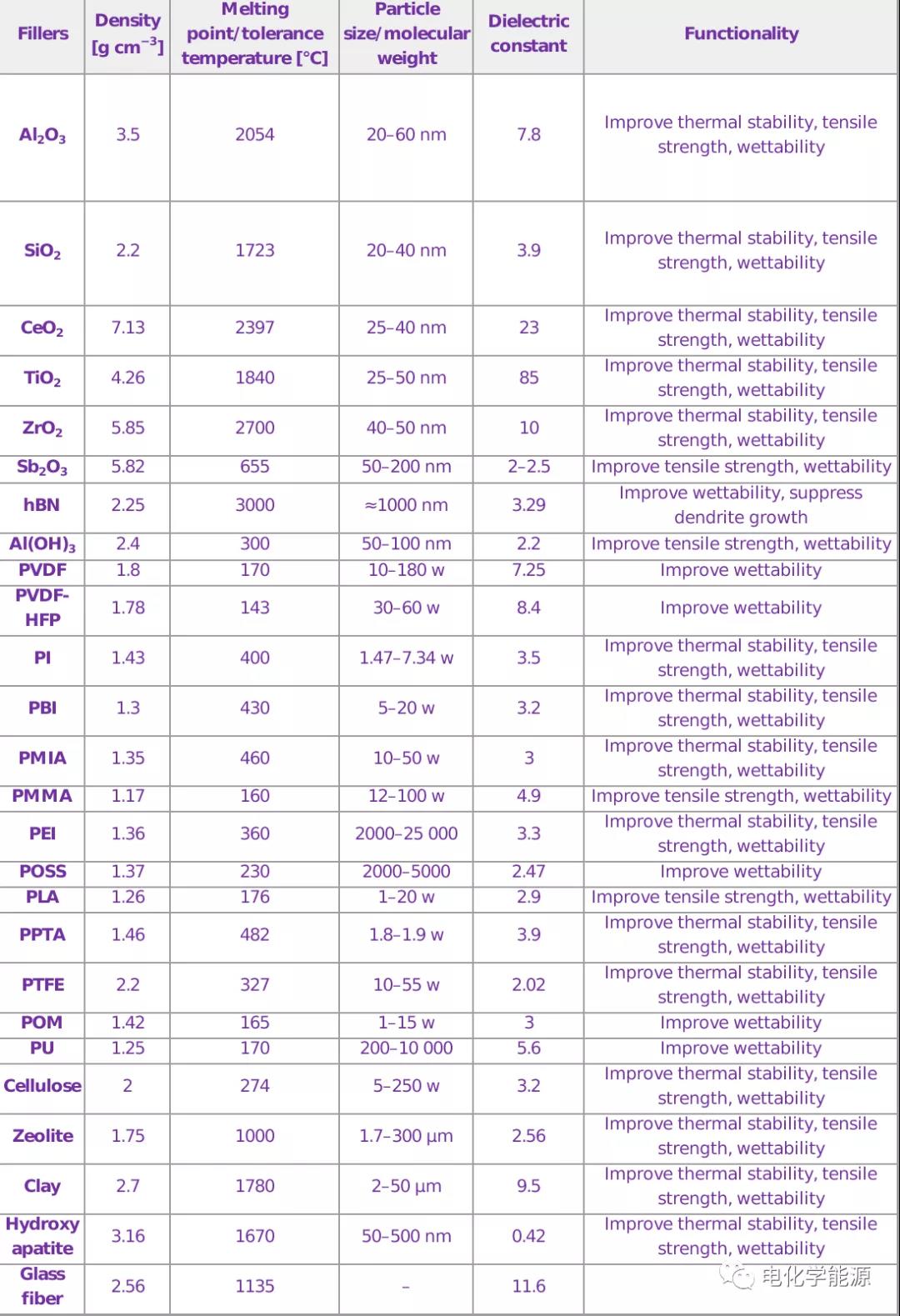

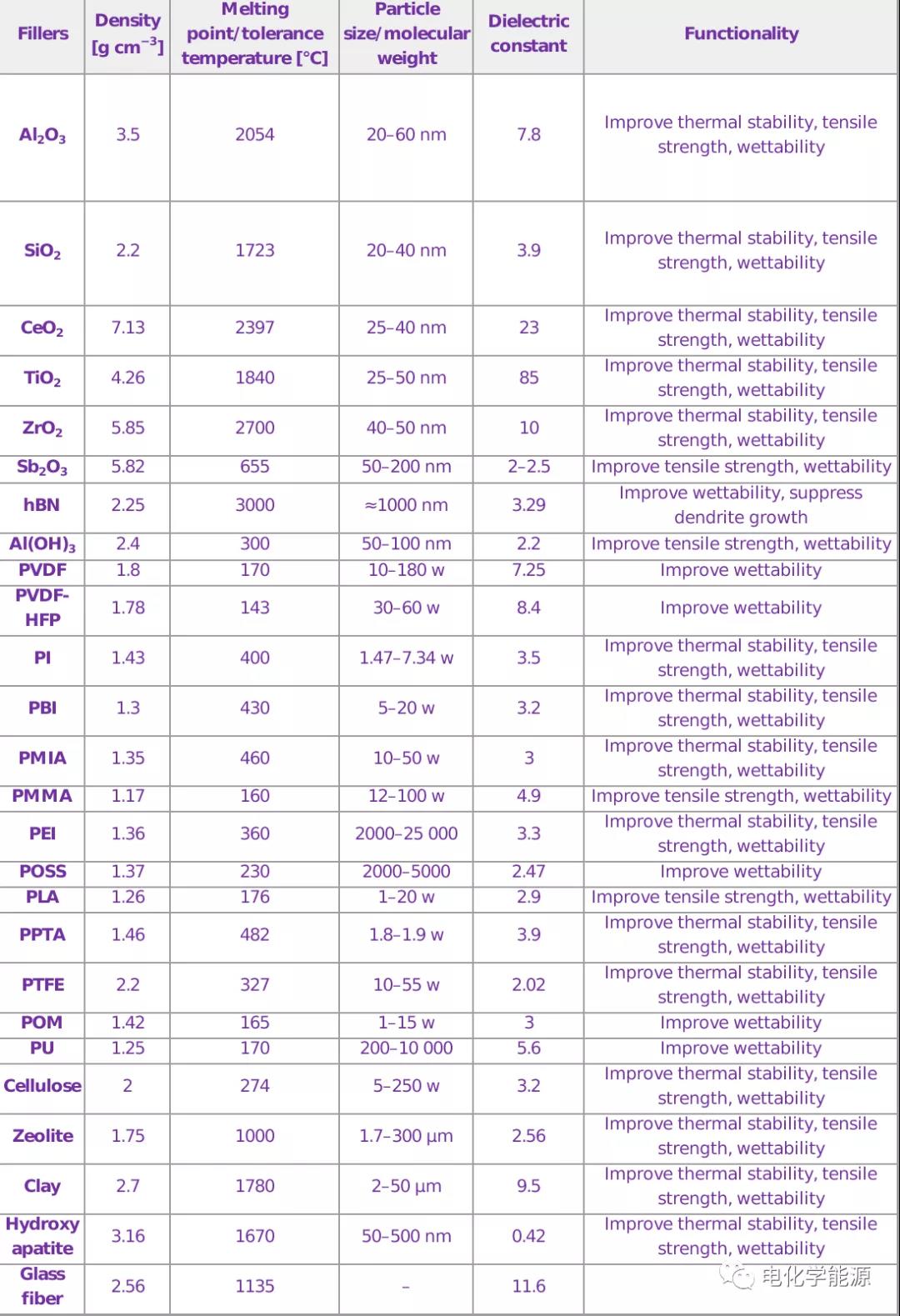

Generally speaking, the type of composite diaphragm is determined by the filler. Therefore, the inherent characteristics of typical fillers are summarized, including density, melting point/tolerance temperature, particle size/molecular weight, dielectric constant, cost, and functionality of the filler. Due to the high melting point and maximum temperature resistance of the filler, the thermal stability of the composite diaphragm is significantly improved, so the composite diaphragm can be operated at high temperatures without thermal runaway. In addition, the particle size and molecular weight of the filler are also important factors to control the uniformity and stability of the composite diaphragm, thereby affecting ion transmission. The surface modification of the filler and the formation of a special structure can improve the wettability and dispersibility of the separator in the polymer matrix. These fillers also form a strong interaction with the polymer matrix, thereby improving the tensile mechanical strength and ionic conductivity of the separator, thereby increasing the rate capacity of LIBS. In short, choosing fillers with different physical properties is particularly important to improve the physical and chemical properties of the composite diaphragm, thereby improving the overall electrochemical performance of LiBS.

Outlook

To manufacture ultra-thin diaphragms to achieve low cost, the future goal is 5µm.

For new materials with high thermal stability, there is an urgent need for high melting point polymer materials as the raw material of the composite diaphragm to ensure the high thermal stability of the diaphragm, such as PI, PMIA, PPS and PEEK.

The most advanced diaphragm performance analysis: advanced characterization techniques, simulation methods, and artificial intelligence (AI) assisted analysis models to determine the necessary conditions for predicting diaphragm performance before assembly.

Multifunctional separator to improve battery performance: The improvement of the separator should not only improve the inherent performance of the original separator, but also improve other battery components. For example, when LIBS overheats and catches fire, the flame-retardant material embedded in the partition can penetrate out to extinguish the fire, thereby ensuring battery safety. In addition, some recent reports indicate that the introduction of positive and negative active materials in the diaphragm will reduce the interface impedance and provide additional capacity.

Sustainable and environmentally friendly technologies and materials, biodegradable polymers such as polylactic acid, polyhydroxyalkanoic acid, PBS and polycaprolactone are expected to gain more research interest in the field of separation.

Composite Separators for Robust High Rate Lithium Ion Batteries

Advanced Functional Materials (IF 16.836) Pub Date: 2021-06-01, DOI: 10.1002/adfm.202101420

Botao Yuan, Kechun Wen, Dongjiang Chen, Yuanpeng Liu, Yunfa Dong, Chao Feng, Yupei Han, Jiecai Han, Yongqi Zhang, Chuan Xia, Andy (Xueliang) Sun, Weidong He

This information is sourced from the Internet for academic exchanges. If there is any infringement, please contact us to delete it immediately