I. Overview of the article.

Metal-organic framework (MOF) is a kind of interesting and useful coordination polymers. Because of its diverse composition, easy synthesis, easy surface functionalization, high surface area, adjustable porosity and adjustable biocompatibility, MOFs has been widely used in hydrogen / methane storage, catalysis, biological imaging and sensing, drug delivery, seawater desalination, gas separation, magnetic and electronic devices, nonlinear optics, water vapor capture and so on. At present, with the rapid development of synthesis methods and surface functionalization strategies, intelligent MOF-based nanocomposites with advanced biological properties have been designed and manufactured to meet the growing demand for MOF materials in biomedical applications.The research group of Professor Yang Yingwei of Jilin University has published a review outlining the synthesis and functionalization of MOF in the biomedical field as well as the latest progress, including the delivery of goods (drugs, nucleic acids, proteins and dyes) for cancer treatment, biological imaging, antimicrobial, biosensor and biocatalysis. Finally, the prospects and challenges in the field of biomedical materials based on MOF are also discussed.

Compared with traditional MOFs, nano-MOFs (NMOFs) has highly ordered porosity, inherent pore size and larger specific surface area, which makes its biological activity and chemical / colloid stability enhanced, surface modification more effective, and biological distribution improved. As traditional nanomaterials for biomedical applications, MOF, including NMOF, has the following advantages: 1) thousands of MOF provide a multi-functional porous material library for a variety of bio-related applications; 2) stable but degradable structures ensure reuse and on-demand use; 3) high specific surface area and porosity facilitate efficient packaging / loading of goods ranging from small molecules to biological macromolecules. In particular, the good dispersion and biocompatibility of NMOF ensure the biosafety of in vivo application.

Second, guided reading of picture and text.

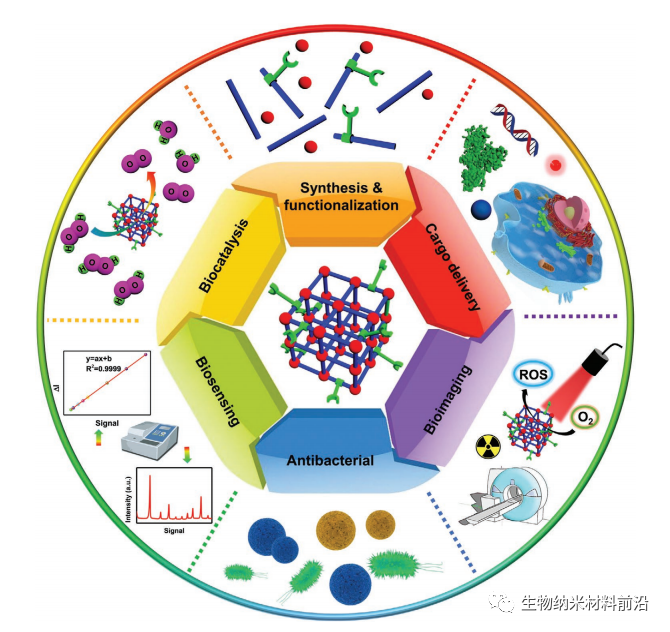

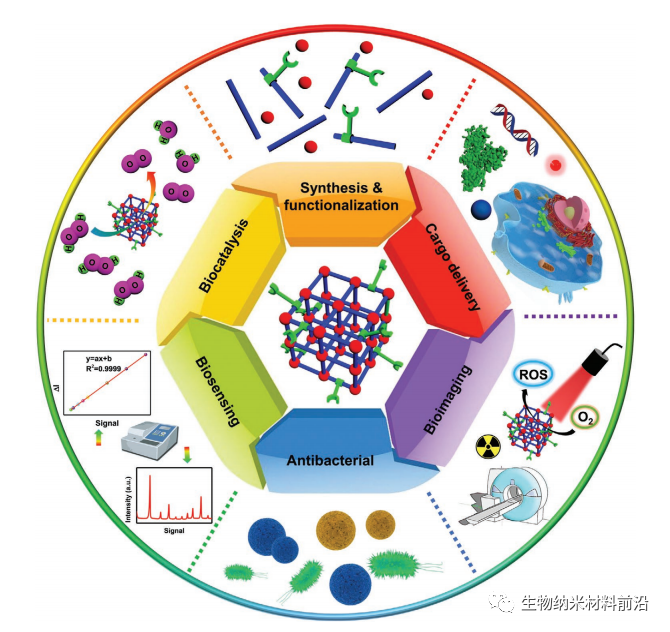

Figure 1.

Schematic diagram of MOF synthesis and functionalization for biomedical applications. Including cargo delivery (i.e. drugs, nucleic acids, proteins and dyes), biological imaging, antimicrobial, biosensor and biocatalysis.

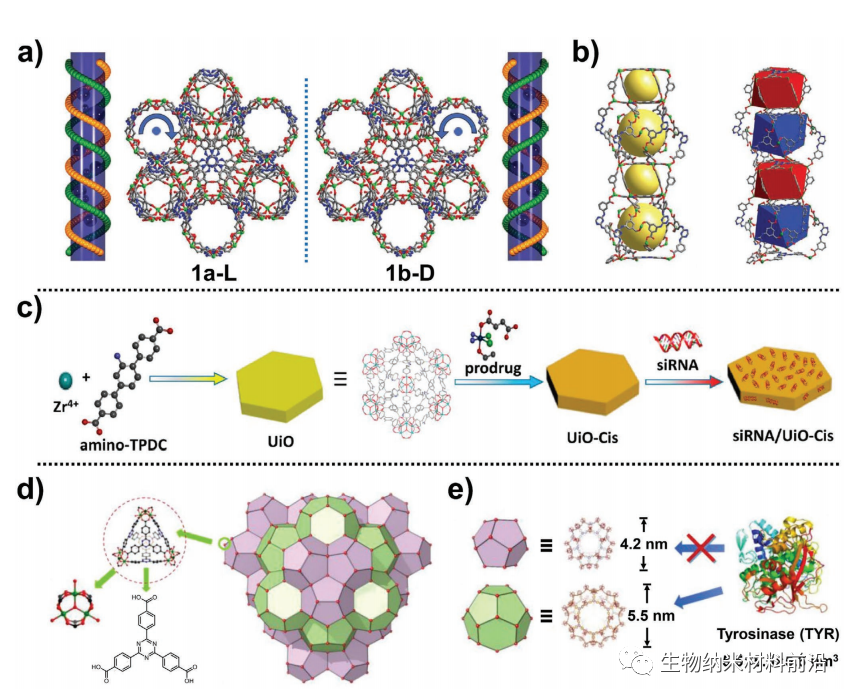

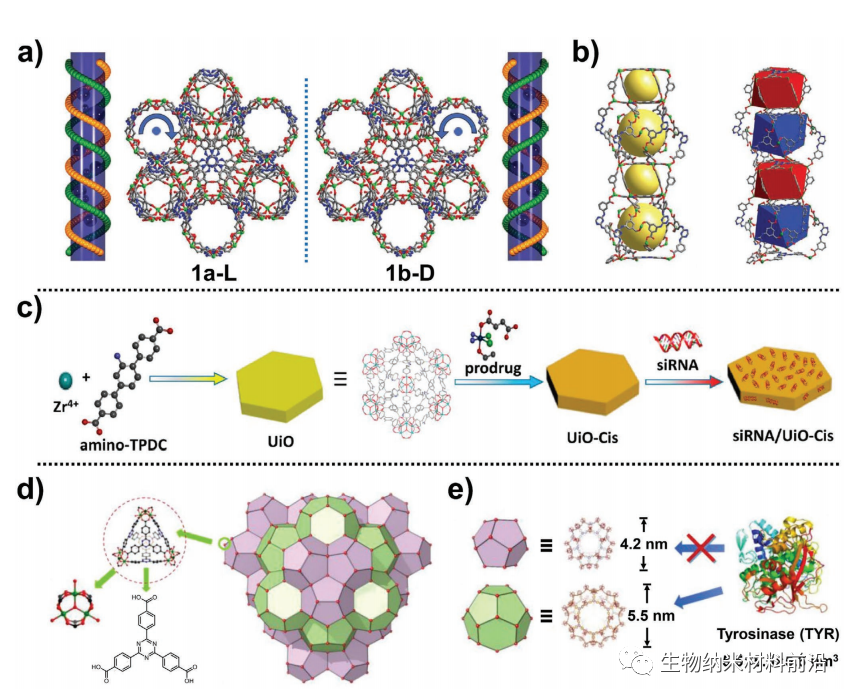

Figure 2.

The side view of the left-handed and right-handed double-stranded 31 helical chains of (a) in 1a-L and 1b-D respectively. Gray, red, blue and green represent two sizes in C, O, N and Zn; (b) 1a-L and the sizes of two types of mesoporous cavities and TYR in the secondary component of siRNA/UiO-Cis preparation diagram; (d) NPCN-333 (Al) for co-delivery of cisplatin and siRNA by triangular and hexagonal prism nano-cages; (c).

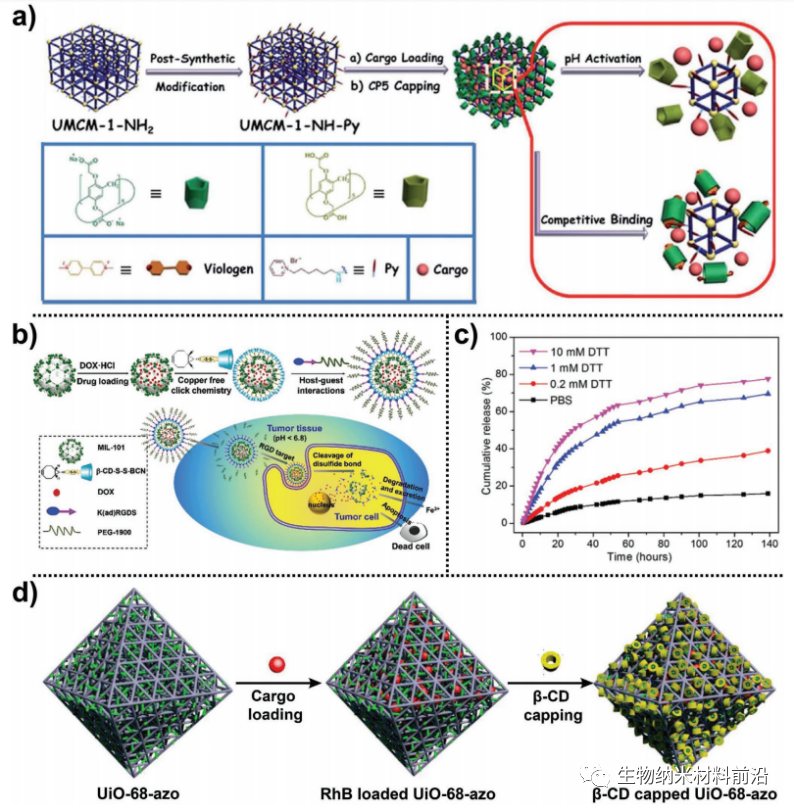

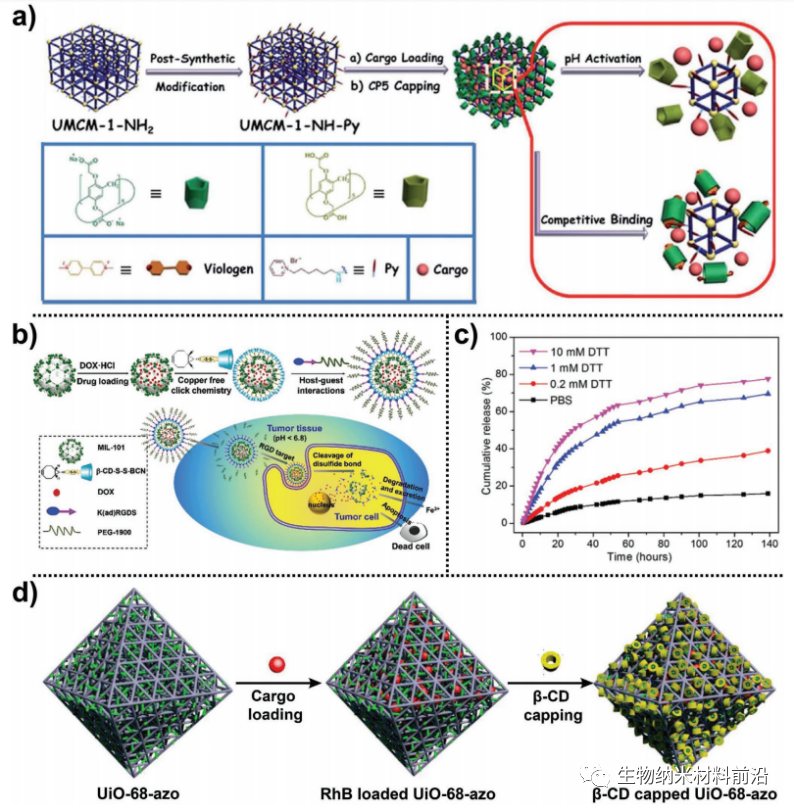

Figure 3.

Schematic diagram of DDS synthesis process and drug release behavior of (a)-based CP5-terminated UMCM-1-NH-Py; (b)-based DDS preparation diagram of Fe-MIL-101-based DDS and its application in tumor therapy and the legend of representative components in the system; (c) based on the DOX release curve of Fe-MIL-101-based DDS under redox stimulation. (d) is based on the DDS preparation process diagram of ¦Â-CD-terminated UiO-68- azo.

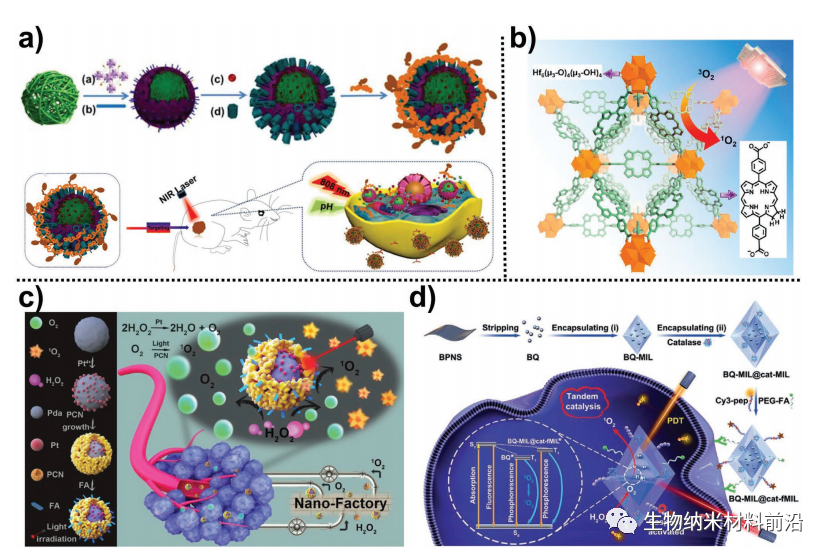

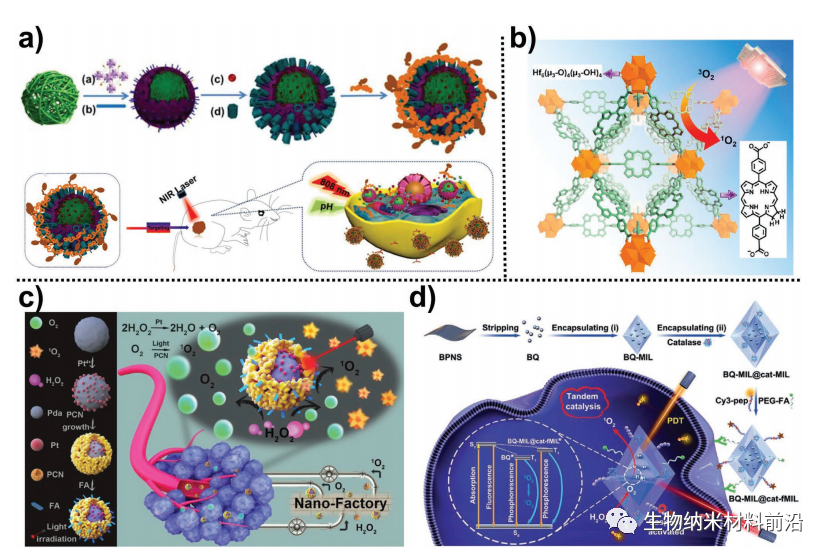

Figure 4.

Schematic diagram of (a) preparation of DDS based on WP6-terminated core-shell MOFs and its application in synergistic photothermal therapy schematic diagram of; (b) DBC-UiO generating 1O2 for PDT under light irradiation schematic description of; (c) Pda-Pt@PCN-FA nanofactory to improve the use efficiency of ROS during PDT in TME. The preparation diagram of (d) tandem catalytic MOF platform and its application in enhancing the therapeutic effect of hypoxic tumor cells by PDT and PTT.

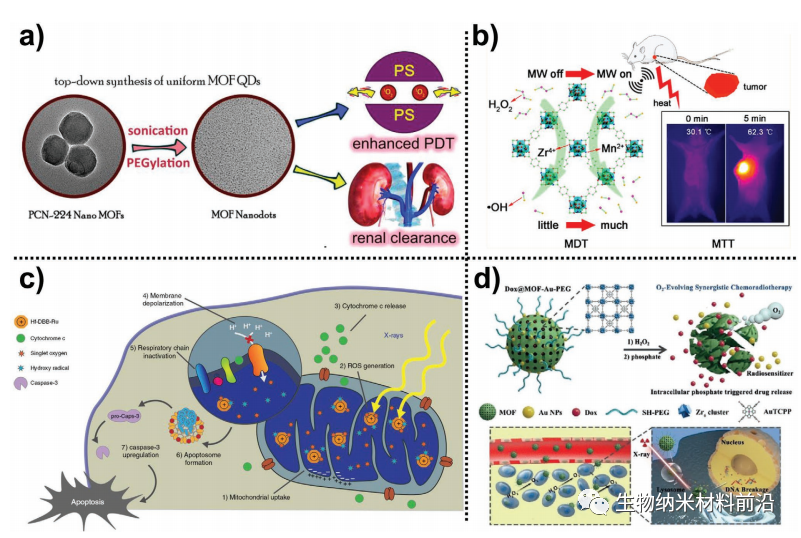

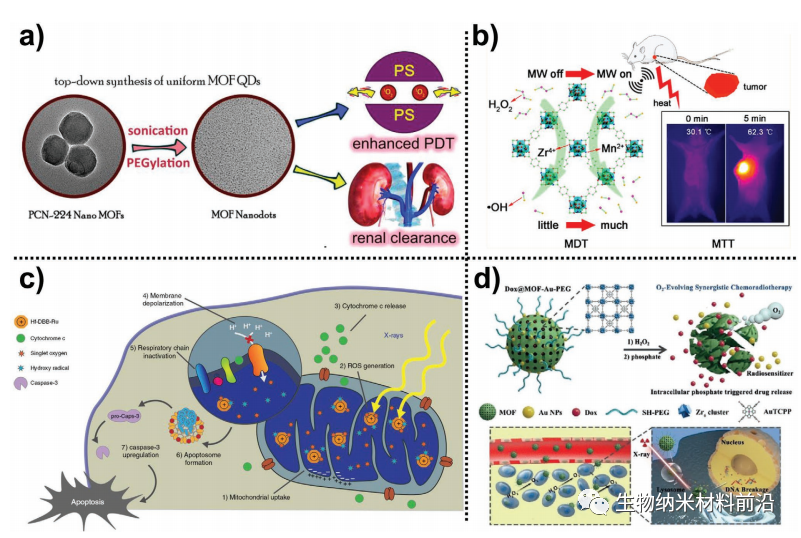

Figure 5.

Preparation of MOF QDs with efficient Renal clearance ability of (a) for Cancer treatment schematic diagram of; (b) Mn-ZrMOF NCs as a nano-platform for tumor co-operation of MDT and MTT schematic diagram of; (c) Hf-DBB-Ru-initiated mitochondrial targeting RT and RDT inducing apoptosis of tumor cells. (d) is based on the schematic diagram of the main components of the nano-hybrid of polyethylene glycol porphyrin Au-NMOF and the mechanism of O2-evolving synergistic radiotherapy and chemotherapy for tumor therapy.

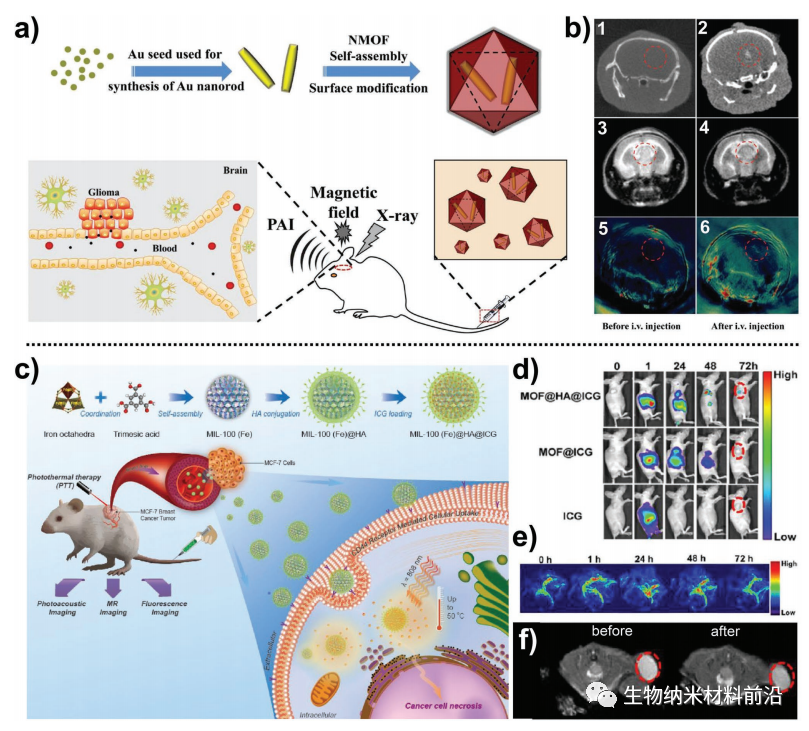

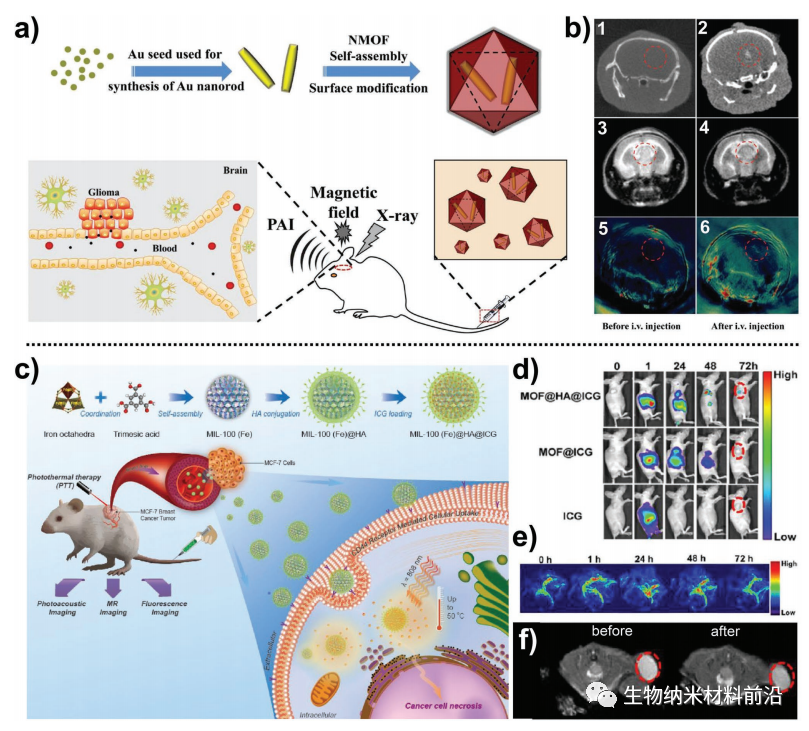

Figure 6.

Preparation schematic diagram of (a) Au@MIL-88 (Fe), application of CT, MRI and PAI imaging in glioma diagnosis before and after intravenous injection of Au@MIL-88 (Fe) nano-platform, CT (b1prime2), MRI (b3prime4) and PAI (b5pg6) images of mice carrying U87 MG before and after intravenous injection of Au@MIL-88 (Fe) nano-platform. Construction of (c) MOF@HA@ICG system and application of FL, PAI and T2-weighted MRI imaging in the treatment of MCF-7 tumor-bearing mice schematic map of MRI images of; (d) FL, (e) PAI and (f) after in vivo injection of various materials.

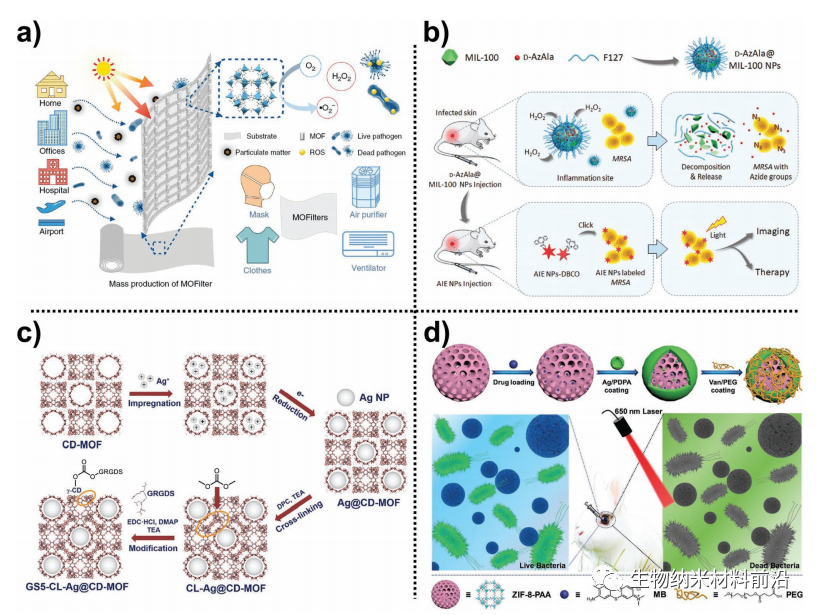

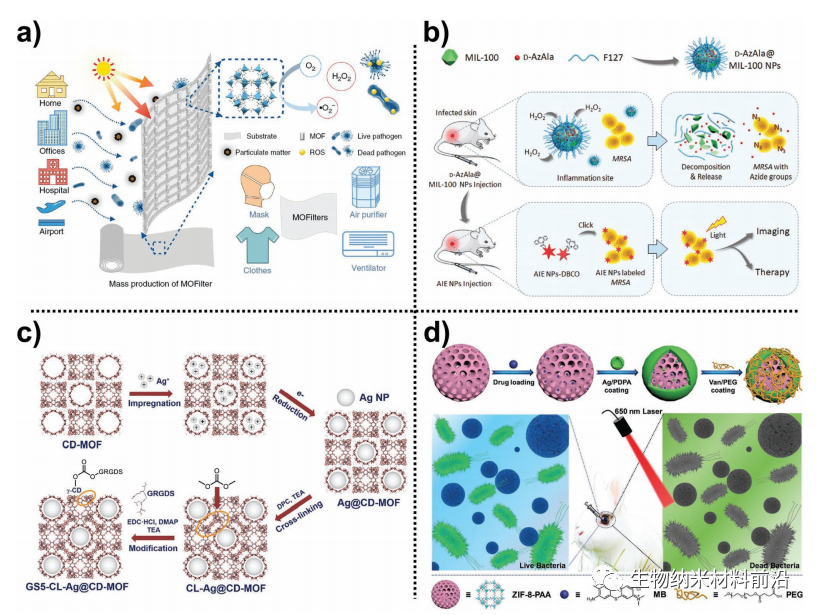

Figure 7.

A) A schematic diagram of the application of ZIF-8-based MOFilter in photocatalysis and efficient sterilization in air pollution and personal protection.

B) the fabrication of MIL-100 (Fe)-based nano-platforms and proposed strategies for in vivo imaging to guide accurate antimicrobial therapy.

C) the preparation process of growing ultra-fine Ag NPs in the pores of CD-MOF and the surface modification of CD-MOF.

D) Synthesis of ZIF-8-PAA-MB@AgNPs@Van-PEG and its application in the treatment of endophthalmitis

Figure 8.

Application of Au NPs@MIL-101@GOx/LOx biosensor in the detection of glucose and lactic acid by SERS proportional imaging of; (d) cells incubated with R-UiO-based biosensors under anoxic (left), normoxic (middle) and aerated (right) conditions.Schematic diagram of (e) Eu3+/Ag+@UiO-66- (COOH) 2 biosensor for H2S gas detection; (f) after adding H2S 0 to 8 minutes, the fluorescence intensity change of Eu3+/Ag+@UiO-66- (COOH) 2 at 615 nm; (g) the linear fitting curve of various NaHS concentrations and the fluorescence intensity change of Eu3+/Ag+@UiO-66- (COOH) 2 at 615 nm. The schematic diagram of (h) GSPs@ZIF-8 manufacturing and using volatile organic compounds to detect SERS in the diagnosis of lung cancer, as well as the selection and binding strategy of (i) GSPs@ZIF-8 biosensors for different size gas molecules.

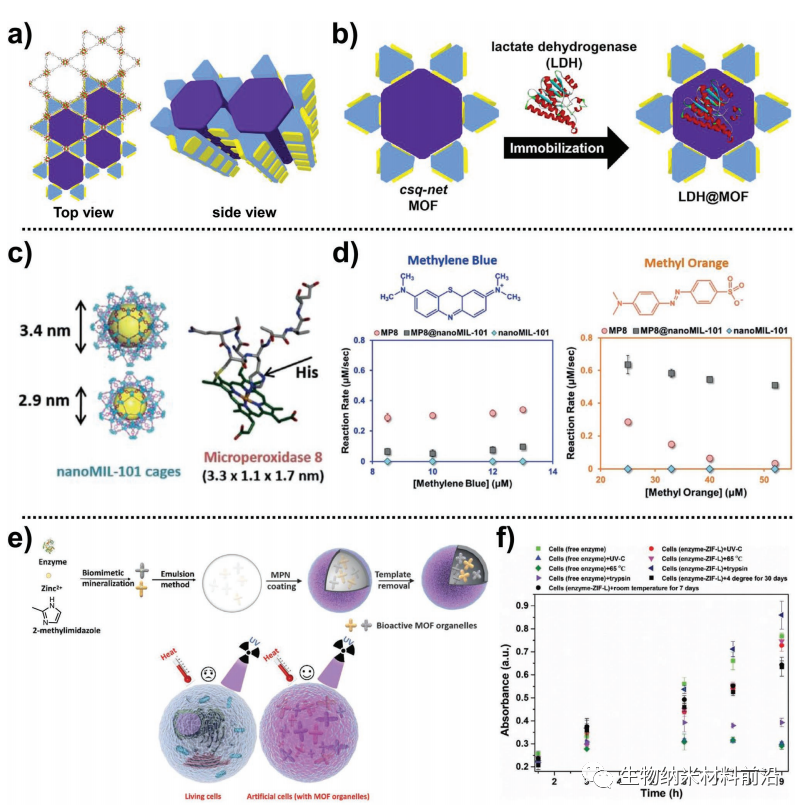

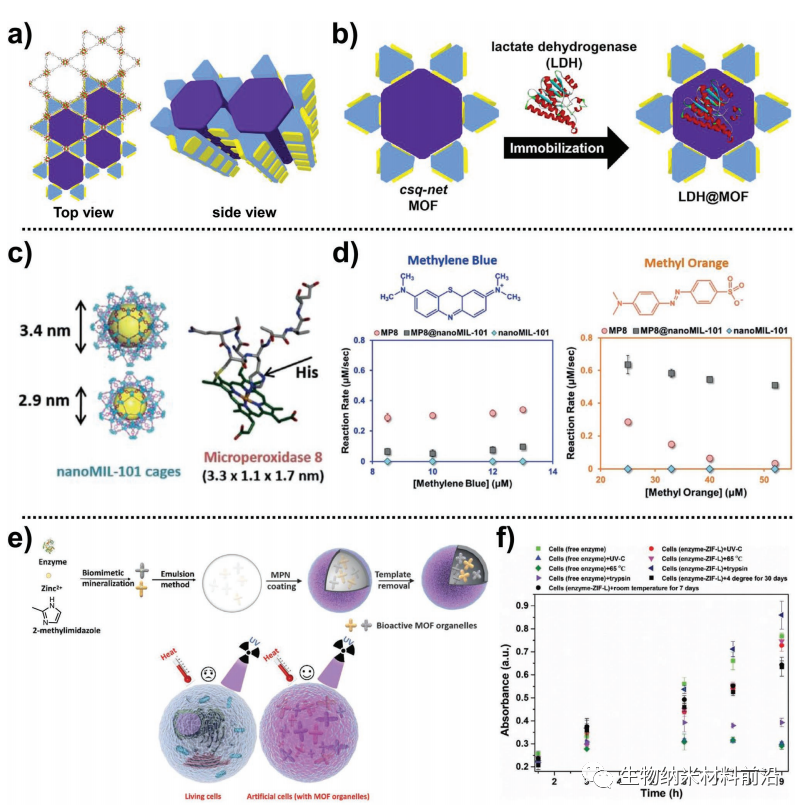

Figure 9.

Top view (left) and side view (right) of (a) Zr-MOFs interconnect hierarchical pore structure schematic diagram of; (b) loading LDH in Zr-MOFs macrohole the transport cage of; (c) NMIL-101 (Cr) and the structure of MP8 degradation efficiency of; (d) free MP8, NMIL-101 (Cr) and MP8@NMIL-101 on positively charged MB and negatively charged MO.Schematic diagram of the manufacturing process of artificial cells with hyperstability and stimulus response of (e); (f) contains the UV-vis absorption curve of the catalytic ability of artificial cells of GOx-ZIF-L under the conditions of UV-C, high temperature (65 ¡æ), trypsin hydrolysis for 3 hours and low temperature (4 ¡æ).

III. Summary of the full text.

This review reviews and discusses the latest advances in biomedical applications of MOF-based composites, including the delivery of carriers (drugs, nucleic acids, proteins and dyes) for cancer therapy, biological imaging, antimicrobial agents, biosensors and biocatalysis. As a multi-functional carrier in biomedicine, MOFs mainly makes use of its adjustable structure and morphology, excellent surface area, high porosity and crystallinity, strong loading capacity, enhanced thermal / chemical stability and different affinity.

At the same time, researchers have been devoting themselves to the development of MOF-based materials, which have strong targeting in biomedical applications and negligible side effects in biomedical applications. However, MOF-based composites still face severe challenges in biomedical applications.

(1) the toxicity of MOFs is the most urgent problem to be solved before clinical research. Due to the diversity of MOFs structure and species, as well as the complexity of the internal environment of organisms, the toxicity of MOFs is not only related to composition, morphology, size and stability, but also to the tolerance of biological tissues. Therefore, the toxicity of various MOFs needs to be comprehensively evaluated. If MOF stents are to be excellent candidates for biomedical applications, then long-term toxicity is the most critical point to consider.

(2) using endogenous or bioactive molecules as ligands and metal ions with high biocompatibility (such as Fe, Ca, Zn, etc.) as metal nodes to construct functional MOFs, is of great benefit to avoid the toxicity of MOFs.

(3) preventing the aggregation and premature removal of MOFs during the cycle is another challenge that needs to be addressed. Severe aggregation can lead to additional toxic side effects. Surface functionalization and size control are often used to solve this disadvantage. Adjusting synthesis methods or other physical and chemical strategies to control the diameter of MOF in the nanometer range; using polymers and supramolecular macrocyclic compounds to functionalize the surface of MOFs; using other entities to adjust the surface potential and binding force is also an effective strategy.

(4) the degradation mechanism and pathway of MOFs need to be studied systematically in vivo, and combined with multimodal imaging to monitor the degradation process of MOFs.

Although MOFs still faces long-term challenges in biomedical application, the significant progress made so far provides a reference cornerstone for the study of toxicity, biodegradability and degradation mechanism.We envisage that MOFs, which has multidisciplinary advantages in the near future, will be further developed in clinical application to improve human health.

This information is from the Internet for academic exchange only. if there is any infringement, please contact us to delete it immediately.