Background introduction.

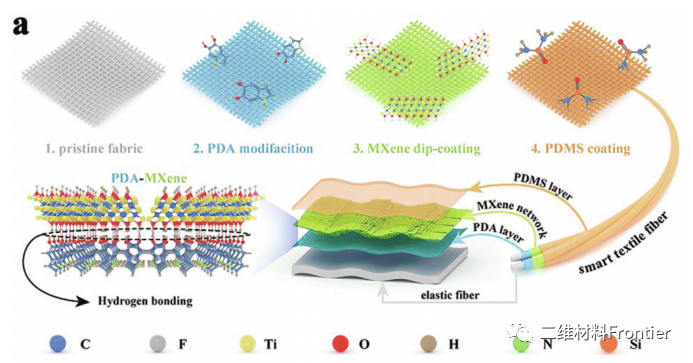

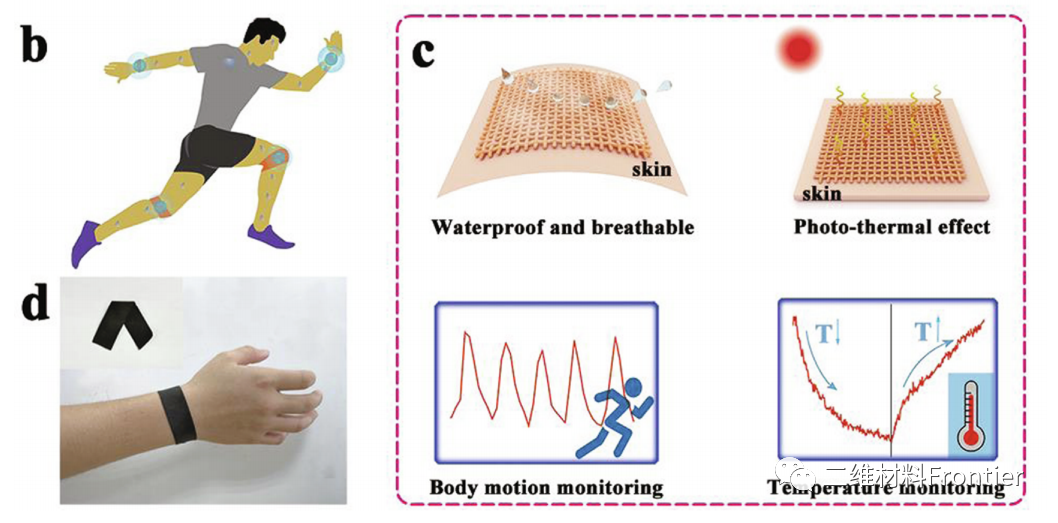

The potential applications of intelligent textile equipment in wearable human motion monitoring, health care and personal thermal management have attracted more and more attention. MXene (Ti3C2Tx) is a new two-dimensional material with remarkable properties, which has been widely used in the field of wearable electronic products. However, the preparation of smart textiles based on MXene and smart textiles that can prevent MXene oxidation is still a challenge.Here, by constructing a multi-core-shell structure, that is, decorating polydimethylsiloxane (PDMS) coating on polydopamine (PDA) modified elastic fabric, and then polydimethylsiloxane coating, a kind of waterproof and breathable intelligent fabric is made. The MXene wrapping the fiber forms a conductive network, and PDMS can not only protect MXene from oxidation, but also give the fabric super hydrophobicity and corrosion resistance. Smart textiles have excellent and durable photothermal and electrothermal conversion properties. More importantly, textile electronics show sensitive and stable strain sensing performance and high thermal coefficient temperature sensing ability.Obviously, this kind of intelligent textile equipment has a broad application prospect in the next generation of integrated wearable electronic devices.

Second, guided reading of picture and text.

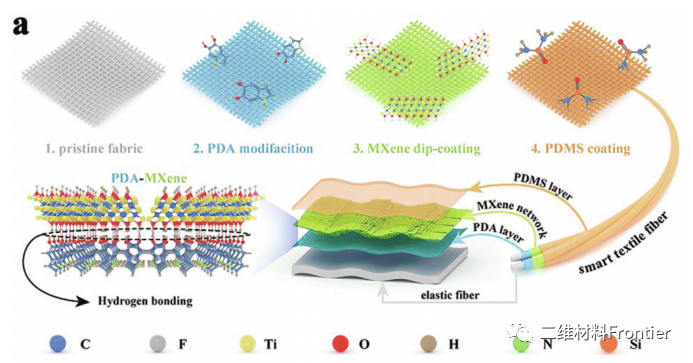

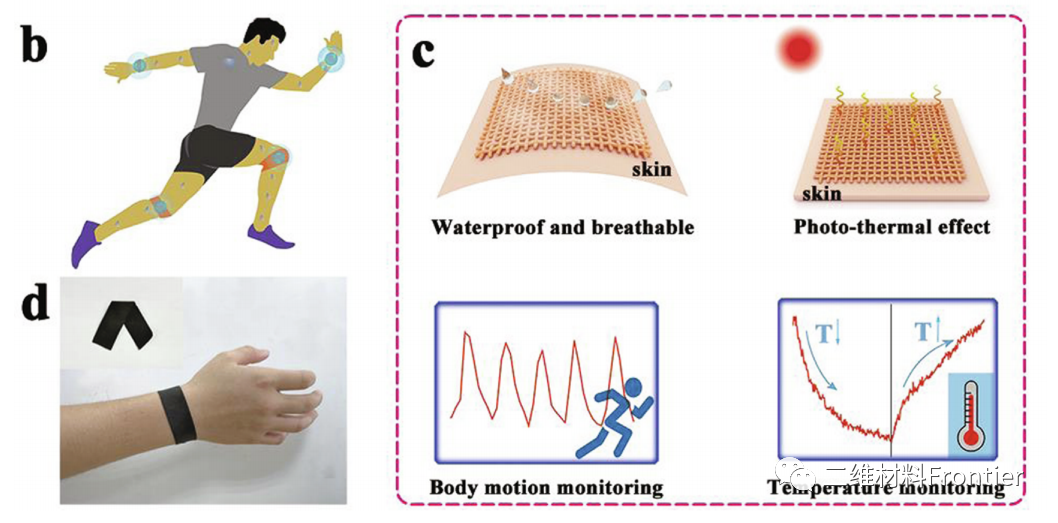

Figure 1. (a) A schematic diagram of the preparation process and structure of PM/PDMS textiles. (b) is attached to the PM/PDMS textile on the joints of the human body to monitor the movement of the human body. (c) has excellent performance and a variety of promising applications. (d) volunteers show photos of textiles as smart strain sensors worn on their wrists (illustration is a picture of a circular textile).

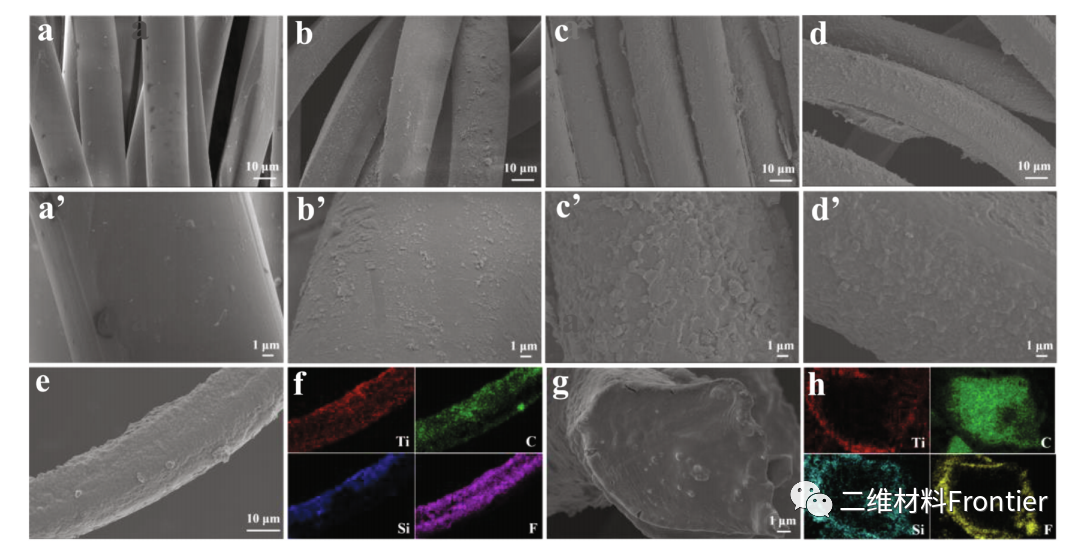

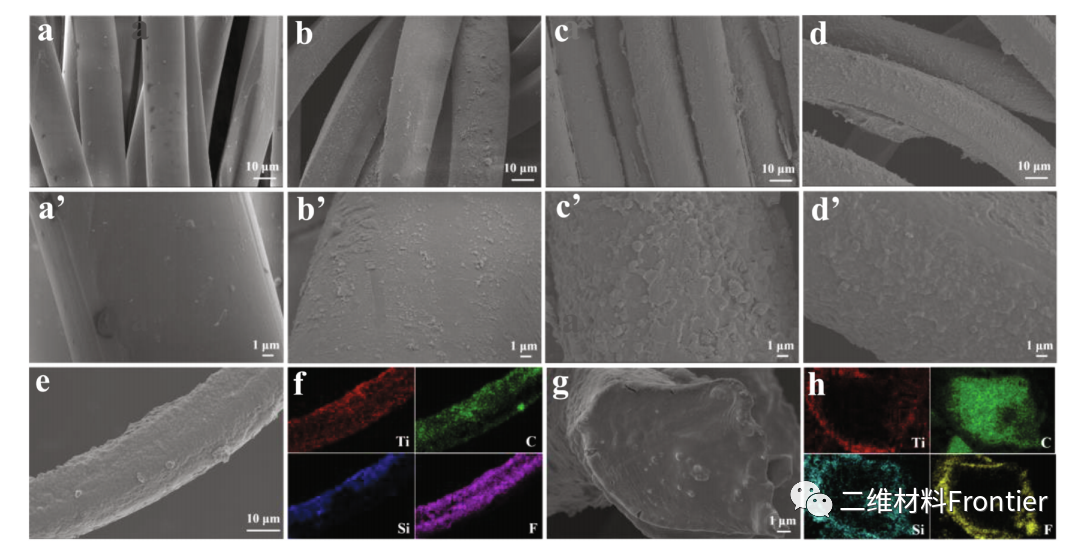

Figure 2. (an and a) original textiles, (b and b) textiles coated with PDA, (C and C) PM-3 textiles and (d and d) PM-3/PDMS-40 textiles. The morphology of individual fibers of (e) PM-1/PDMS-40 textiles and the corresponding EDS element mapping image of (f). The cross-sectional SEM images of individual fibers of (g) PM-1/PDMS-40 textiles and the corresponding EDS mapping images of (h) Ti, C, Si and F.

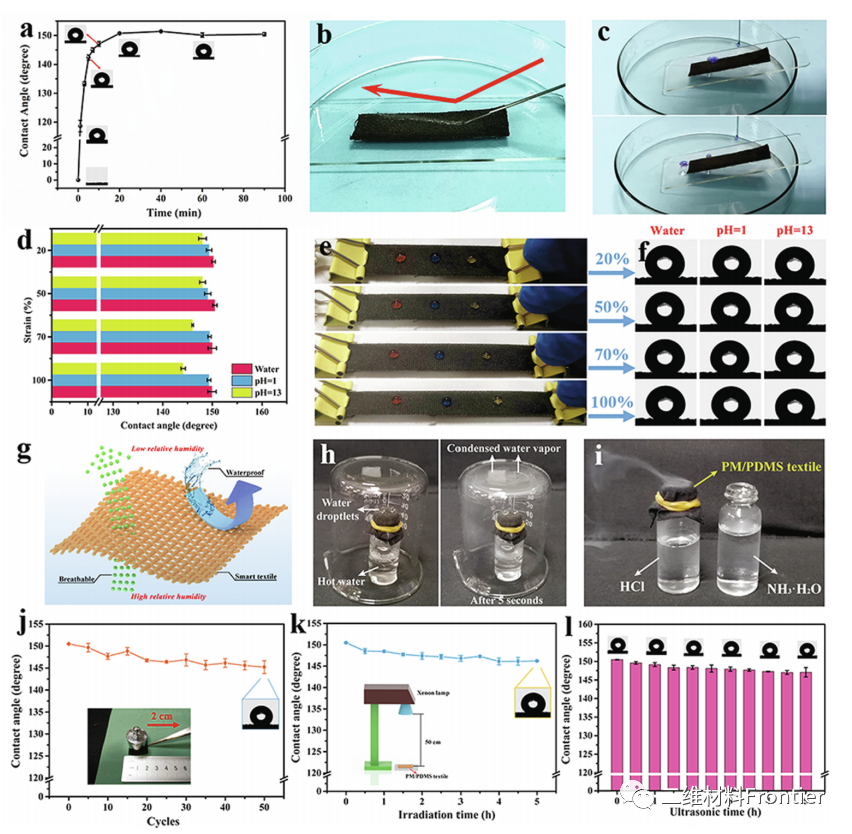

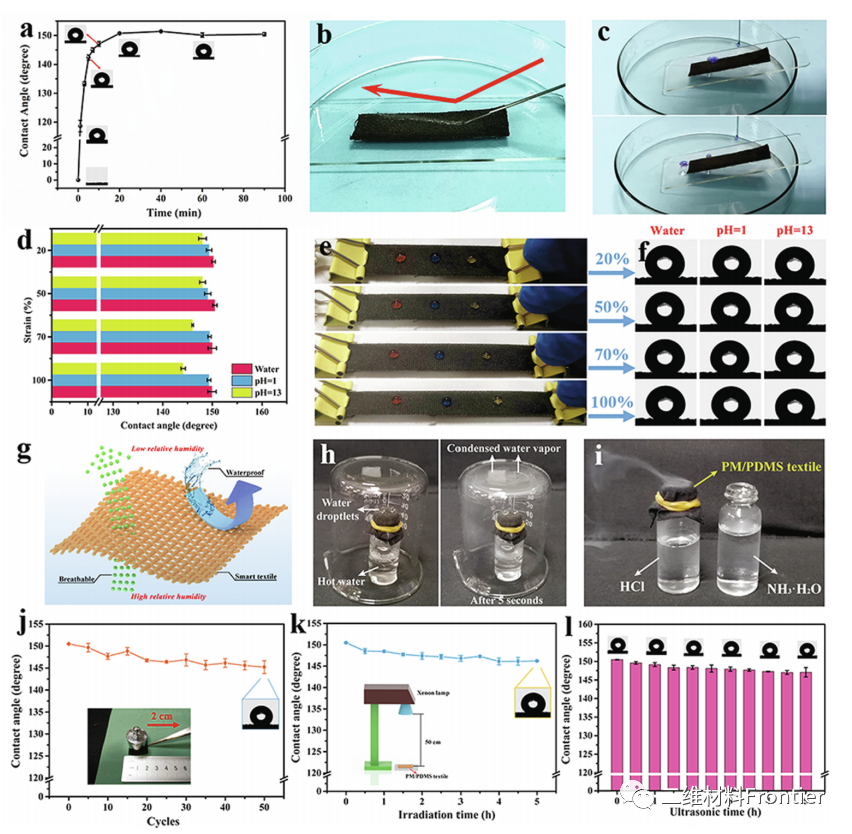

Figure 3. Water contact angle (WCA) of (a) PM-3 textiles as a function of impregnation time in PDMS solution. Optical photos of (b) sprayed on the surface of PM/PDMS textiles. (c) dynamic wetting test using dyed water on PM/PDMS fabrics CA of water, acid (pH=1) and alkaline (pH=13) solutions on the surface of (d) PM-3/PDMS-40 textiles. (e) photos of water droplets and liquid droplets with pH 1 and 7 under different strain, (f) corresponding CA images. Schematic diagram of waterproof and air permeability of (g) PM//PDMS textiles. (h) shows the water vapor transport properties of breathable fabrics. (I) Photos of hydrogen chloride gas flowing out of vials covered by PM/PDMS textiles (j) changes of WCA of PM-3/PDMS-40 textiles with wear cycles; these inlays are photos of composite textiles worn by sandpaper at a weight of 50g and WCA images after 50 cycles, respectively. The change of (k) PM-3/PDMS-40 textile WCA with light irradiation time, the mosaic is the schematic diagram of ultraviolet irradiation test and the schematic diagram of WCA image after 5 hours of irradiation. The WCA of (i) PM-3/PDMS-40 textiles varies with the ultrasonic washing time.

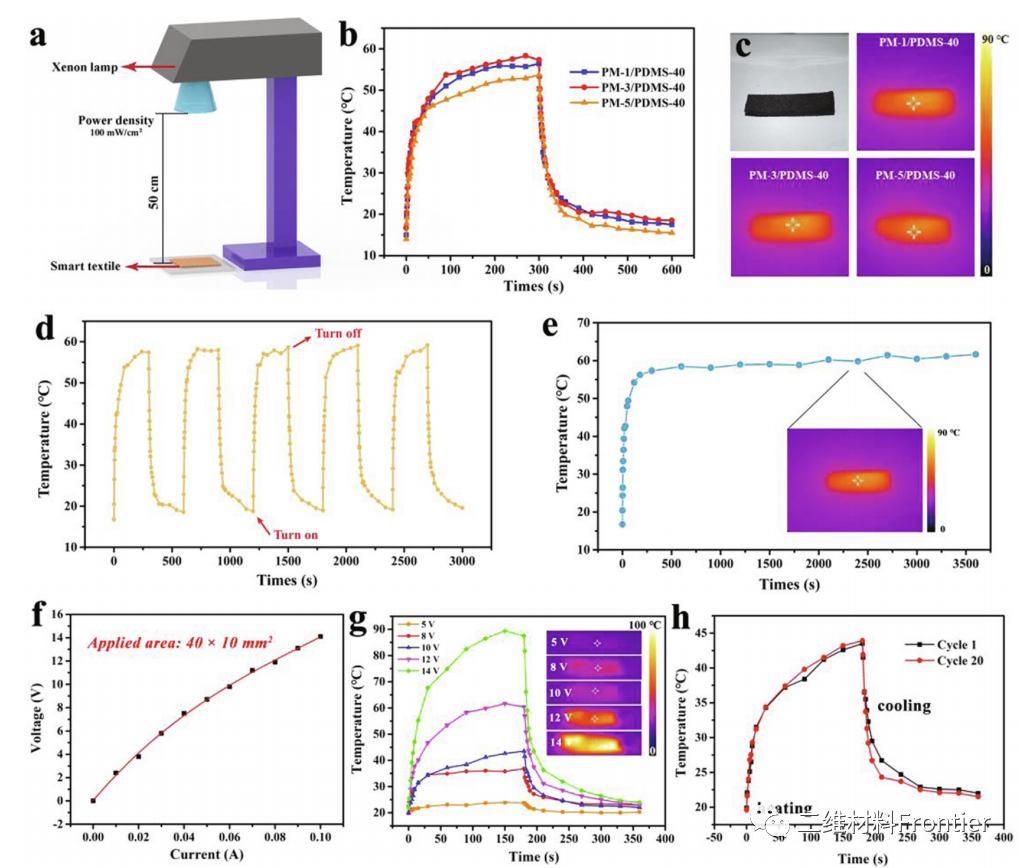

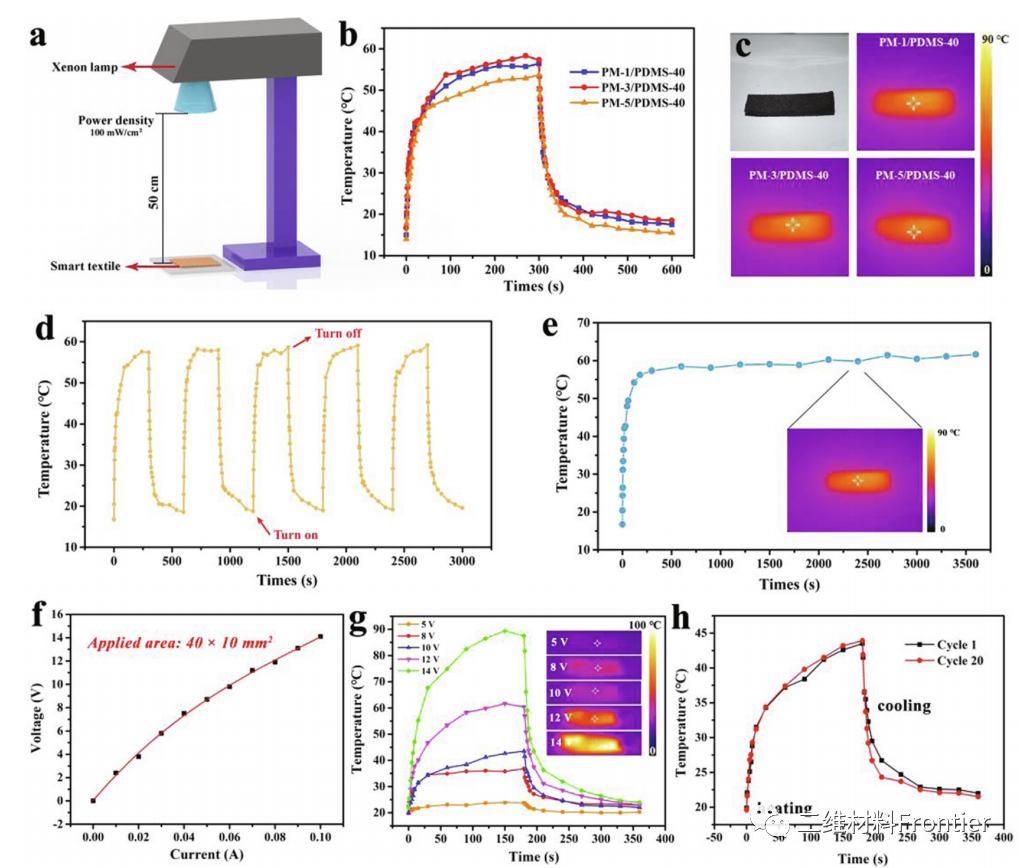

Figure 4. Schematic diagram of (a) simulated photothermal test model (power density = 100mW/cm2). The temperature-time curve of PM/PDMS-40 textiles prepared by (b) with different MXene coating time. Corresponding optical photos and infrared images of (c) photothermal conversion of (d) PM-3/PDMS-40 textiles in five heating and cooling cycles.Under the irradiation of (e) 3600s, the photothermal stability of 100mW/cm2 is the power density, and the infrared image of 2400s test textile is embedded. Voltage-current curvature of (f) textiles. The temperature-time curve of (g) PM-5/PDMS-40 textiles at different voltages (the mosaic shows the corresponding infrared image of the saturation temperature). Temperature stability of (h) PM-5/PDMS-40 textiles in 20 hot and cold cycles.

Fig. 5. The electrical conductivity of (a) PM textiles is a function of the dipping time in MXene solution. Change of electrical conductivity of (b) PM-3 textiles. When (c) PM-1/PDMS-40 textiles were exposed to a temperature of ~ 25 ¡ãC and the humidity of 136 h (d) batches was 60%, the change of drug resistance of PM-1 textiles was the relative resistance of PM-1/PDMS-40 textiles to strain. (e) the relative resistance response at different tensile rates under 50% strain. The response time and recovery time of (f) smart textile sensor under 10% strain, and the stretching rate is 1500mm/min. Cyclic durability test of (g) 30mm/min textile sensor under 20% strain. Embedding: strain detection performance of two randomly selected areas in a cyclic test. The PM/PDMS textile sensor monitors the sensing signals of (h) elbow bending, (i) fixation and (j) walking.

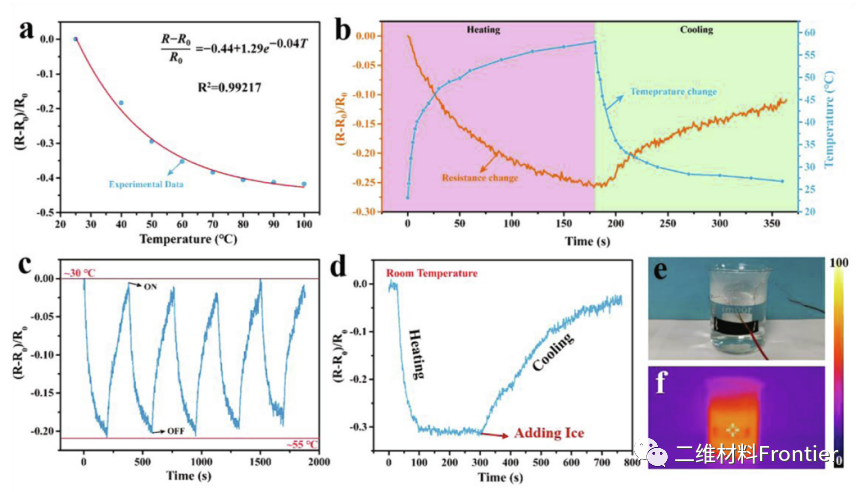

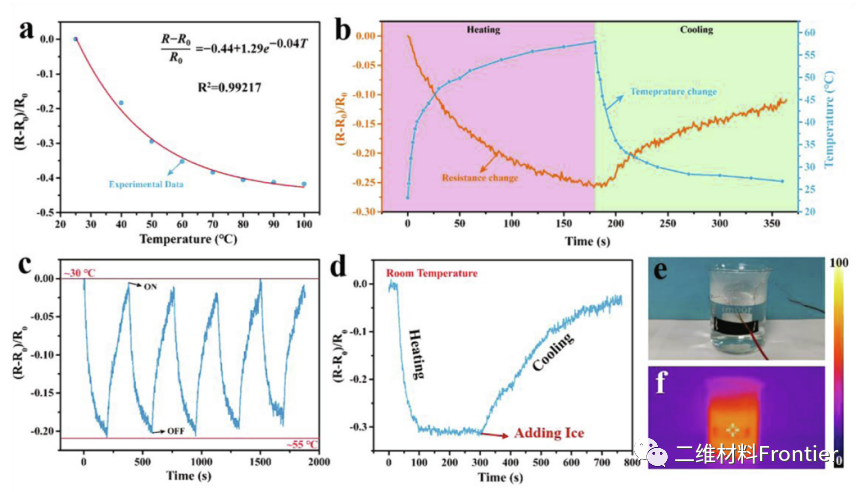

Figure 6. Relative resistance of (a) PM-3/PDMS-40 textiles with temperature in the range of 25-100C. Relative resistance and temperature change of (b) PM-3/PDMS-40 textiles under light-induced heating and natural cooling. (c) temperature sensing durability of a variety of heated and cooled smart textiles from 30C to 55C. (d) is installed on the beaker with the textile sensor to simulate the change of relative resistance during ambient temperature monitoring. The optical photos of the (e) experimental model and the corresponding infrared images of (f).

III. Summary of the full text.

In a word, the super-hydrophobic and breathable multi-functional MX alkenyl fabric was prepared by layer-by-layer dipping method. The MXene plate can be assembled to the surface of PDA modified fiber by bending force and hydrogen bond, and then it can be well protected after PDMS coating. The designed smart textile electronics not only show super hydrophobicity and satisfactory air permeability with 151¡ã CA, and allow the transport of gas including but not limited to water vapor, but also put forward that the superior photothermal and electrothermal effects have good recyclability and durability for external photons and electrons. In addition, the conductive composite fabric has excellent strain sensing properties and can be used to monitor human motion. Surprisingly, due to the unique NTC characteristics of MXene, smart textiles have real-time temperature sensing, high TCR and good durability.Therefore, the perfect integration of these functions can make intelligent all-in-one textiles with good mechanical robustness and environmental stability become a promising application in human motion and temperature monitoring, health care and personal thermal management.

This information is from the Internet for academic exchange only. if there is any infringement, please contact us to delete it immediately.