Jin Yizheng research group of Zhejiang University reported the controllable synthesis of metal copper carboxylate modified NiOx nanocrystals (NiOx Cu) and its application in quantum dot light emitting diodes (qled). The project team used NiOx Cu nanocrystalline thin film prepared at low temperature (~ 135 ℃) as hole injection layer, which made the external quantum efficiency (EQE) of red qled device reach 17.5%, and the T95 working life at 1000 nits initial brightness is more than 2800 hours.

Qled uses quantum dots as the light-emitting center, which is compatible with the stable, efficient, high color purity optical properties and solution processable properties of quantum dots. It is expected to realize high-performance LED devices fabricated by all solution process, which has great potential in the application of display devices and solid-state lighting. NiOx based thin films are widely used as hole injection layers in qled devices (adv. funct. Mater. 27, 170, 4278, 2017; adv. funct. Mater; Nanoscale 10, 11103, 2018; Nanoscale 11, 1021, 2019; Adv. Funct. Mater. 30, 1907265, 2020)。

However, NiOx thin films in reported high performance qled devices are prepared by precursor solution method. In the precursor solution method, high temperature (> 275 ℃) treatment is usually required to drive the chemical reaction to convert the precursor film into NiOx film in situ. High temperature process seriously limits the development of qled device structure design and flexible devices. In order to solve this problem, researchers are committed to developing low-temperature NiOx film-forming process. For example, Chen Shuming research group of South University of science and technology successfully prepared NiOx thin films with high crystalline quality and good flatness at 150 ℃ by combustion method, and realized the preparation of flexible qled devices (nanoscale 11, 1021, 2019). Unfortunately, the performance of qled devices based on NiOx thin films prepared by combustion method is far inferior to that based on NiOx thin films prepared by high temperature precursor solution method.

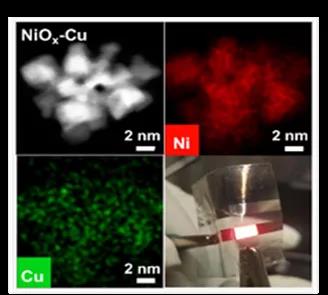

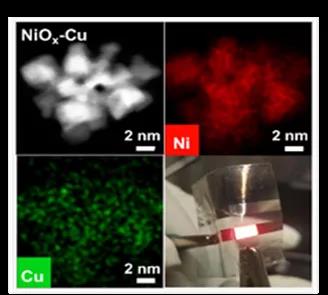

Based on the above considerations, the research group of Jin Yizheng of Zhejiang University is based on NiOx nanocrystalline solution which can form film at low temperature. In order to solve the problem of poor conductivity of pure NiOx thin film, the research group developed the surface modification method of metal Cu carboxylate. Without changing the size, morphology, crystal structure and Fermi energy level of NiOx nanocrystals, this modification method can greatly improve the electrical conductivity of the device, thus realizing high performance red light qled device. The device efficiency and working life are better than those of the device with NiOx thin film as hole injection layer prepared by precursor solution method. The results reveal that the conductive properties of hole injection layer play an important role in the performance of qled, and provide guidance for the design of NiOx based hole injection layer in high performance qled, and provide new ideas for the fabrication of flexible devices.

This information is from the Internet for academic exchange only. If there is any infringement, please contact us to delete it immediately