I. Overview of the article.

Flexible sensor is one of the common directions in the sensor field, and the sensing material and structure are the main aspects that affect the performance of the sensor. A flexible pressure sensor based on graphene / MXene-PDMS@ sponge is studied in this paper. A set of integrated sensors with high sensitivity (0.053kPa-1), high stability (2000 cyclic loading) and variability (0-35kPa detection limit) was fabricated by using the porous skeleton structure of sponge and the high conductivity and synergism of graphene and MXene. In the rectal model pressure detection experiment, the sensor array can effectively detect static pressure, systolic pressure and corresponding abnormal pressure detection. The experimental results show that the sensor has a good application prospect for the detection of rectal pressure.

Second, guided reading of picture and text.

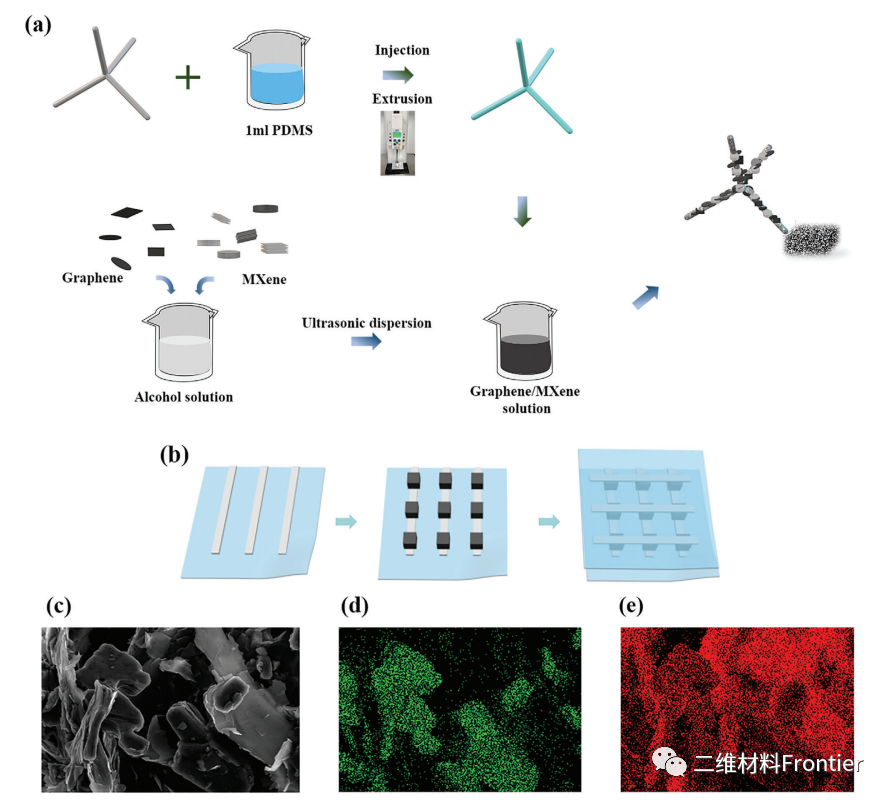

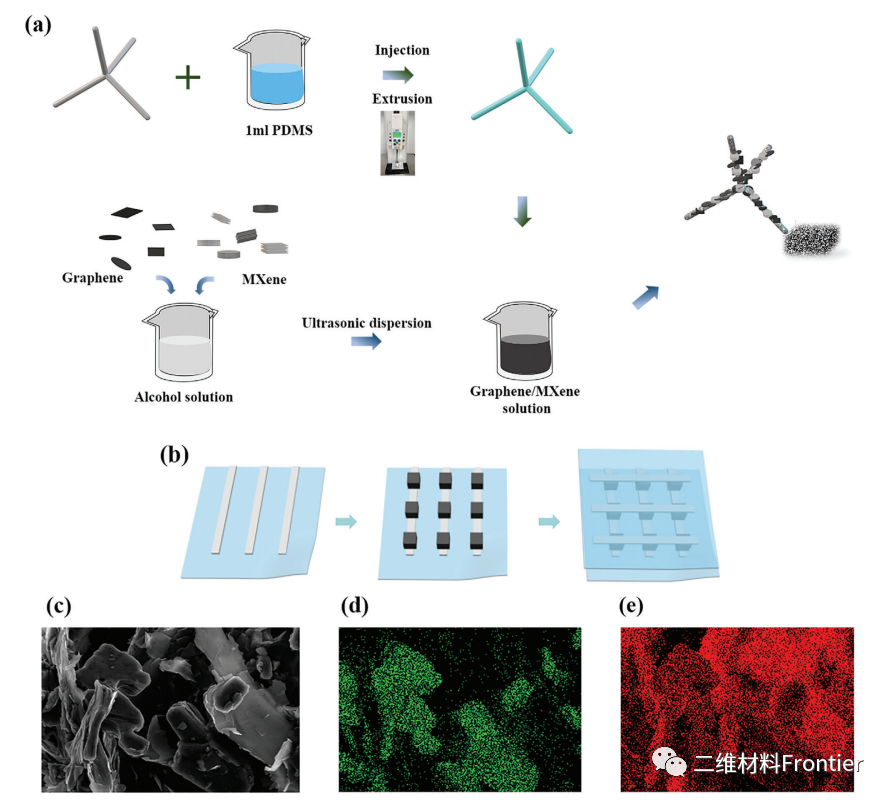

Figure 1.

A) the preparation flow chart of graphene / MXene-PDMS@ sponge flexible pressure sensor. B) flowchart of graphene / MXene-PDMS@ sponge flexible pressure sensor array. C) graphene / MXene SEM image-PDMS@ sponge elastic pressure sensor. D) EDS diagram of titanium. E) EDS diagram of C element.

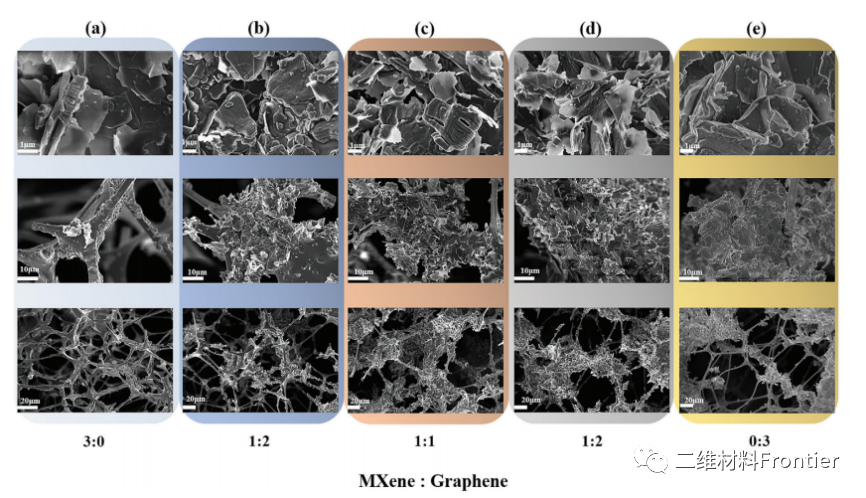

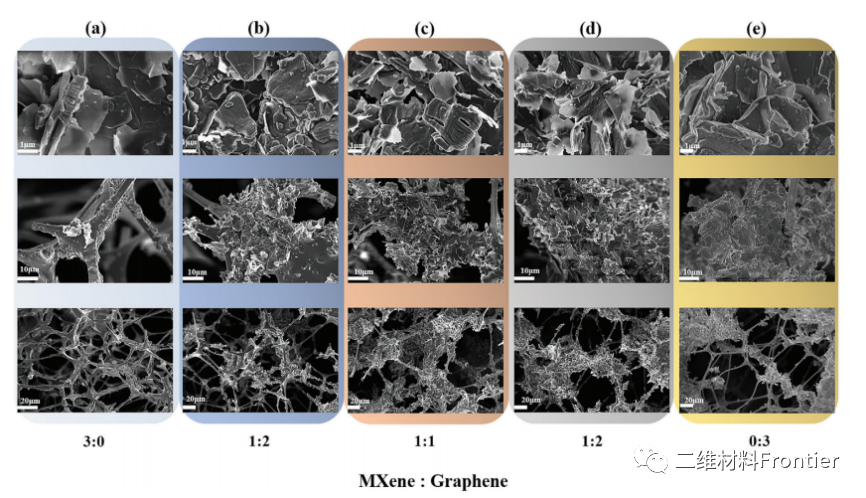

Figure 2.

A) the mass ratio of MXene to graphene in the graphene / MXene-PDMS@ sponge flexible pressure sensor is 3:0. B) 2:1. C) 1:1. D) 1:2. E) 0:3.

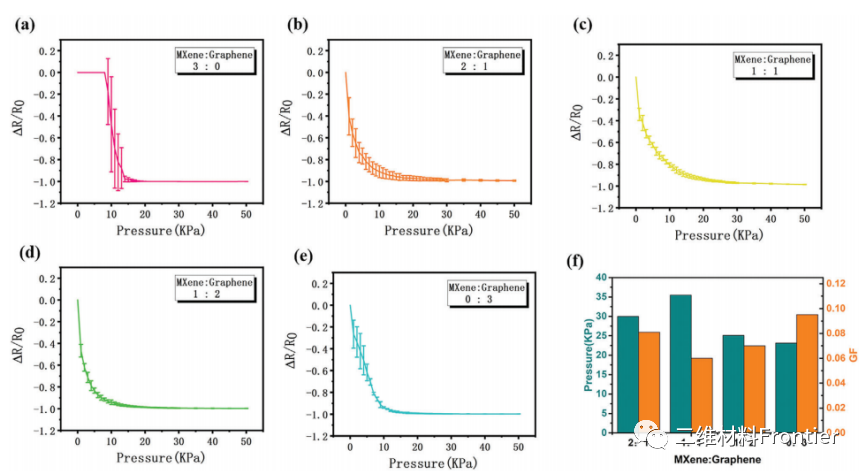

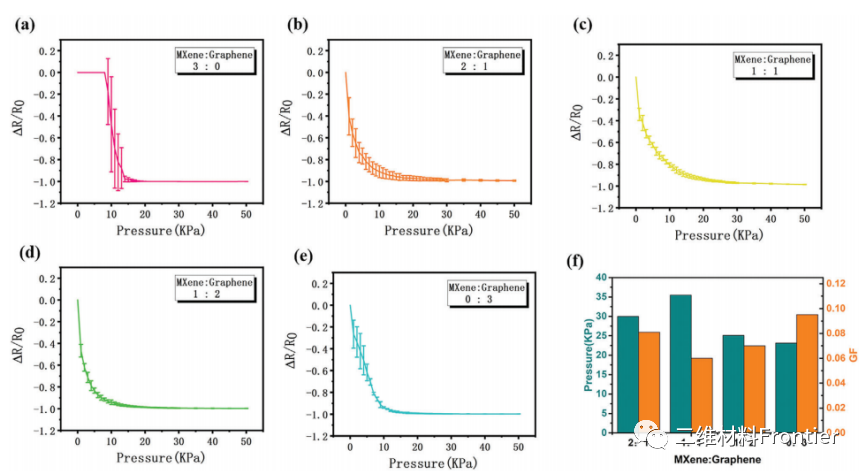

Figure 3.

The mass ratio of MXene to graphene in the sensitivity test chart of the sensor at 3:0, 2:1, 1:1, 1:2 and 0:3 is expressed respectively. F) comparison of sensitivity and detection range of different ratios of diene and graphene.

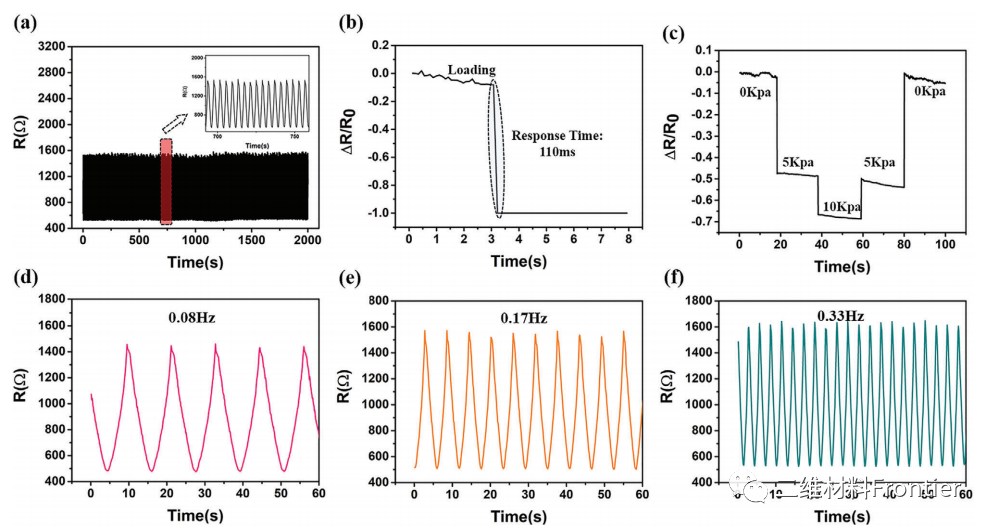

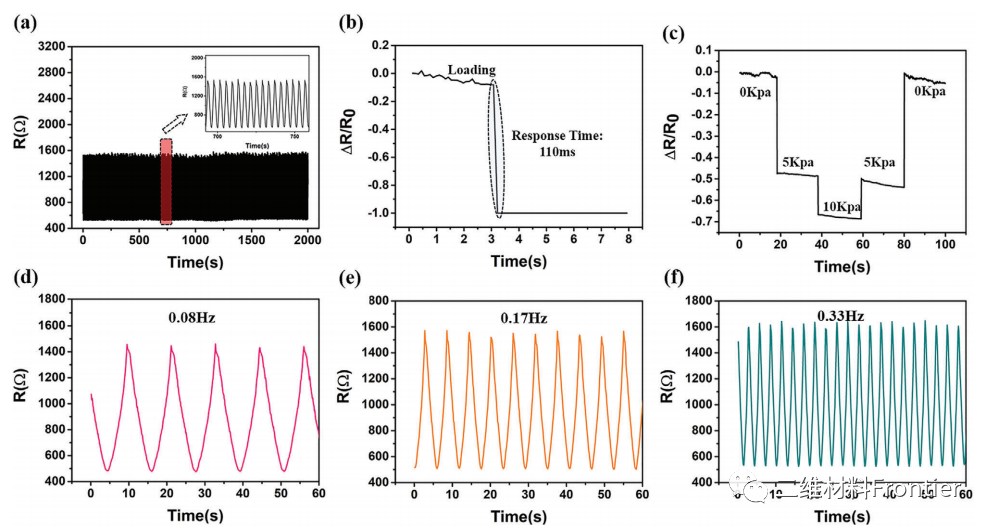

Figure 4.

A) graphene / MXene-PDMS@ sponge sensor 2000 cycle unloading experiment. B) Sensor response time test. C) trapezoidal loading and unloading experiment of sensor. D) load-unload experiment of sensor under 0.08Hz. E) 0.17 Hz. F) 0.33 Hz.

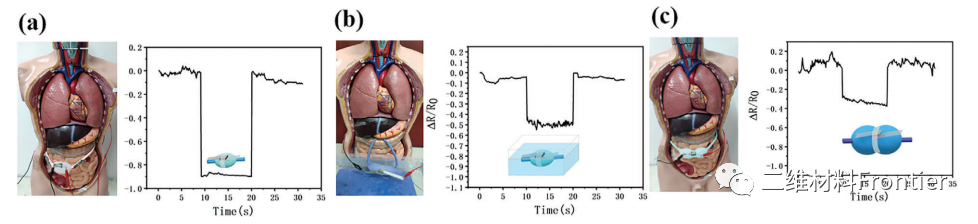

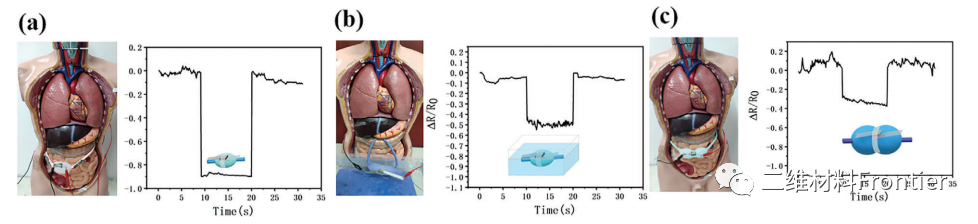

Figure 5.

A) use graphene / MXene-PDMS@ sponge sensor to detect rectal model pressure. B) backstepping model for underwater pressure detection. C) pressure detection of rectangular model (local pressure anomaly).

III. Summary of the full text.

In short, graphene, MXene and PDMS are fixed in a sponge-based graphene / MXene-PDMS@ sponge flexible pressure sensor. Because of the low Youngs modulus and viscosity of PDMS, graphene / MXene can be stably immobilized in the sponge. Using the synergistic effect of graphene and olefin oxide, there is a good balance between sensitivity and detection limit. The sensitivity of the sensor is high, the detection limit of 0% mi 80%, more than 2000 loading and unloading experiments, with good consistency. The rectal model pressure detection experiment using the sensor array can produce a good response to the signal under different conditions, and has the response to distinguish different conditions. The sensor array prepared by the sensor array also has good resolution. In the next step, the stretchable electrode of the sensor array will be studied to achieve a stretchable flexible pressure sensor array. The sensor has a good application prospect in rectal detection and plays an important role in the medical monitoring of artificial intelligence.

This information is from the Internet for academic exchange only. if there is any infringement, please contact us to delete it immediately.