I. Overview of the article.

Molybdenum trioxide (MoO3), as the conversion cathode of lithium-ion battery (LIBs), has attracted wide attention in recent years. However, in the long-term charge-discharge process, the rate capacity is poor, the reaction kinetics is slow, and the capacity decay is fast, which seriously hinders the large-scale commercial application. In this paper, abundant oxygen vacancies and MXene nanowires are introduced into MoO3 nanoribbons by hydrazine reduction and electrostatic assembly to accelerate ion and electron diffusion / transport kinetics. MoO3 x/MXene heterostructure has the advantages of accelerated ion diffusion kinetics, enhanced electrical conductivity, extra active sites caused by oxygen vacancies and strong interface contact, so the prepared MoO3 x/MXene heterostructure has good lithium ion storage performance. First-principles calculations show that the adsorption and electrical conductivity of MoO3 x/MXene heterostructures to Li+ ions are significantly improved. Therefore, the reversible lithium ion storage capacity of the composite is 1258mAhg # 1 at 0.1 Ag-1 and 474mAhg-1 at 10 Ag-1, which is significantly higher than that of moo3-based anode materials previously reported. More importantly, the composite is made of commercial LiFePO4 into a complete LIB, which shows an unparalleled energy density of 330Whkg-1.

Second, guided reading of picture and text.

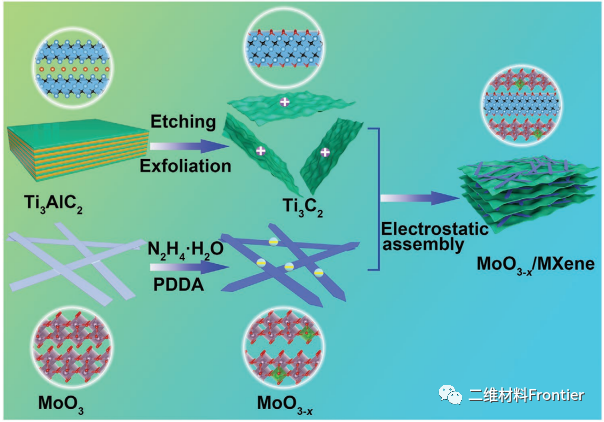

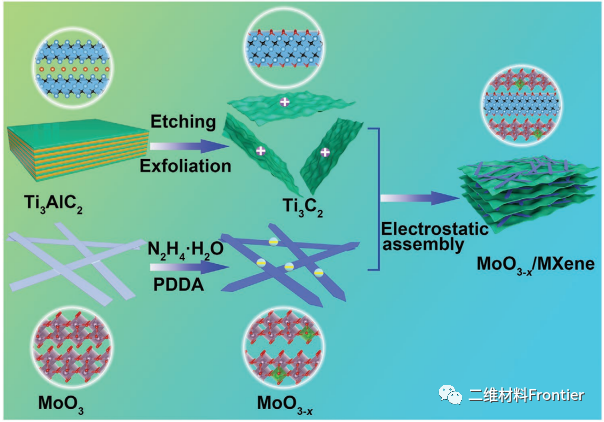

Figure 1.

Schematic diagram of MoO3-x/MXene heterostructure preparation. It includes the preparation of oxygen-rich MoO3-x and MXene nanowires, and the subsequent electrostatic assembly between negatively charged MXene nanowires and positively charged MoO3-x nanowires.

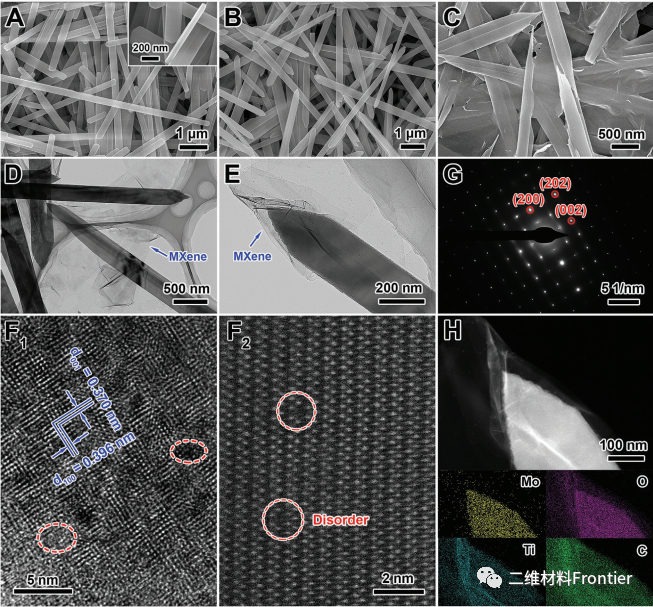

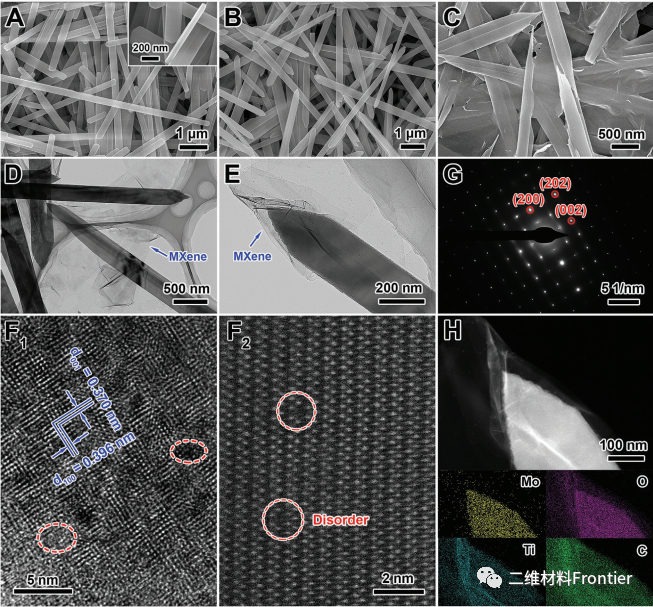

Figure 2.

Morphological identification. A) pure MoO3, B) MoO3 x and C) SEM images of MNM-1 heterostructures. D F1) TEM, F2) aberration corrected high angle annular dark field scan TEM, G) SAED and H) EDS element image heterostructure.

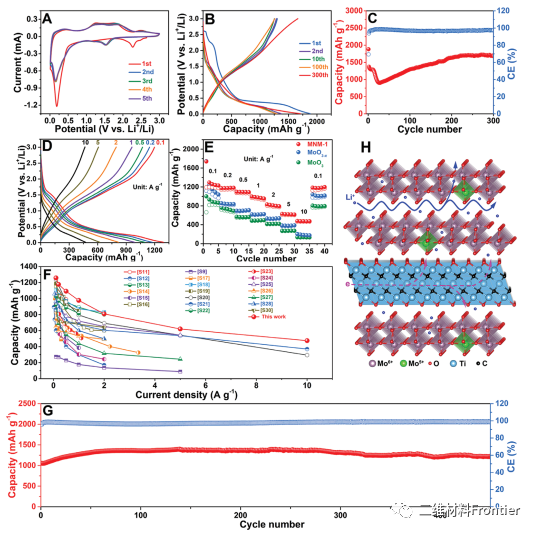

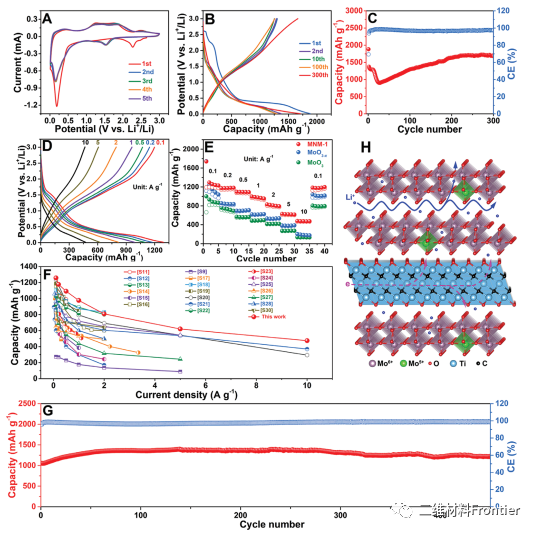

Figure 3.

Electrochemical Li+ storage performance of MNM-1 heterostructure. A) the CV curve at a scanning rate of 0.2 mV s B) the electrostatic charge-discharge (GCD) curve of MNM-1 heterostructures at 0.2Ag-1. ; C) 0.2 A g-1 cycle performance. D) the GCD curve of MNM-1 composites at different current densities; E) the specific capacity of MNM-1 composites at different current densities; F) the rate capacity at different current densities. G) long-term cycle performance of 0.5 A g-1 H) schematic diagram of lithium ion diffusion and electron transfer path.

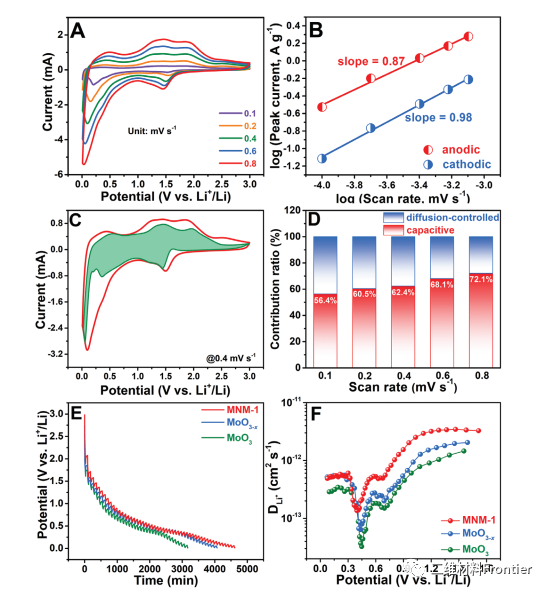

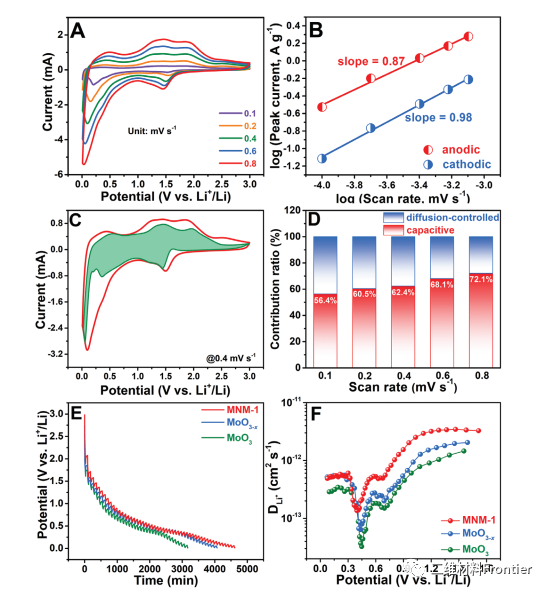

Figure 4.

Electrochemical kinetic analysis of Li+ storage performance of MNM-1 heterostructure. A) CV curves at different scanning rates. B) the relationship between peak current and scanning rate. C) at a scanning rate of 0.4 mV s, the contribution of capacitive charge storage to the total capacity (shadow region) 1. D) the contribution rate of capacitance control behavior at different scanning rates. E) GITT curve, F) GITT curve of pure MoO3, MoO3-x and MNM-1 heterostructures to calculate the diffusion coefficient.

III. Summary of the full text.

To sum up, oxygen-rich vacancy MoO3 x/MXene heterostructures were synthesized by hydrazine treatment and electrostatic assembly, and used in high-performance lithium-ion batteries and supercapacitors. A large number of oxygen vacancies and the incorporation of MXene nanowires can greatly increase the intrinsic and extrinsic conductivity of MoO3 nanoribbons, improve the kinetics of electron / ion diffusion / transport, and greatly increase the electrochemical active sites of MoO3 nanoribbons. Due to the internal and external synergistic effect and the close contact between MoO3-x nanosheets and MXene nanowires, the prepared MoO3-x/MXene heterostructures show good electrochemical performance. The composite has a high lithium ion storage capacity of 1258 mAh g 1 and excellent rate performance (10a g 1 is 474mAh g 1), which is higher than that of the most advanced MoO3 based anode materials at present. At the same time, the prepared lithium-ion battery has high energy density (330 Wh kg-1) and good cycle performance. This work provides a good opportunity for the controllable assembly of other high-performance composites in the future for energy conversion and storage.

This information is from the Internet for academic exchange only. if there is any infringement, please contact us to delete it immediately.