已传文件:photo/1631586161.png

1. Article overview

Aerogel is a highly porous structure that does not cause the collapse of the solid network by replacing the liquid solvent of the sol with air. Different from traditional manufacturing methods, additive manufacturing AM has been applied to manufacture three-dimensional aerogels, and its applications have customized geometric shapes, designed pore morphologies, multi-material structures, and so on. So far, three main AM technologies extrusion, inkjet, and stereolithography followed by a drying process have been proposed to additionally manufacture 3D functional aerogels. 3D printed aerogels and porous scaffolds have broad application prospects in tissue engineering, electrochemical energy storage, controlled drug delivery, sensing, and soft robotics. In this article, the steps in aerogel and porous scaffold AM are discussed in detail, and a general framework for these AM is provided. Then, different post-printing processes are processed to achieve porosity after drying and provide mechanical strength and function after drying heat or chemical treatment. In addition, the application of 3D printed aerogel/porous scaffolds made of various materials is also emphasized.

Two, graphic guide

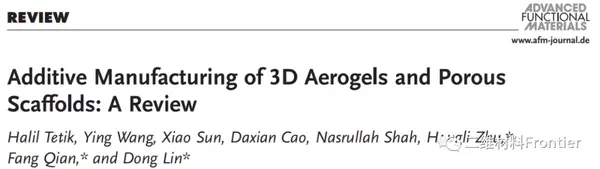

Figure 1. The main flow chart of the 3D printing strategy used to make custom-shaped aerogels.

The process starts by synthesizing a printable ink, and then applies a 3D printing process to cure the ink with the desired shape. After the 3D printing process, using an appropriate drying method, it can eliminate the liquid component without damaging the solid network. Finally, thermal or chemical processes are applied to increase mechanical strength or provide functions.

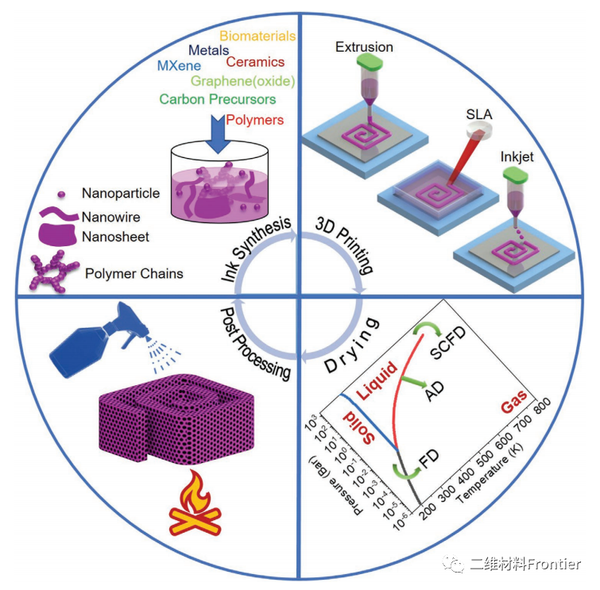

Figure 2. Time development diagram of 3D printed aerogels made of various materials.

The range of materials used in the EBP method includes synthetic polymers, natural polymers, reduced graphene oxide, pristine graphene, bioceramics, and MXenes. The range of materials used with SLA includes silicon dioxide and reduced graphene oxide. The range of materials used together with IBP includes composite materials of reduced graphene oxide, silver nanowires, and reduced graphene oxide.

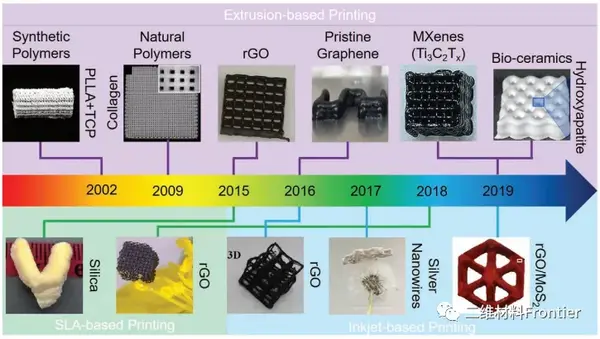

Figure 3. Printability test comparison chart for various inks of EBP.

A A digital image of a paste-like graphene oxide-based ink with a concentration of 20 mgmL−1 extruded through a microneedle. b Viscosity as a function of shear rate. c) Storage and loss modulus as a function of graphene oxide ink shear stress. d The effect of calcium chloride gelation on the rheological properties and printability of graphene oxide solutions. e The rheological properties and printability of manganese-based inks after adding functional agents to the ink formulations.

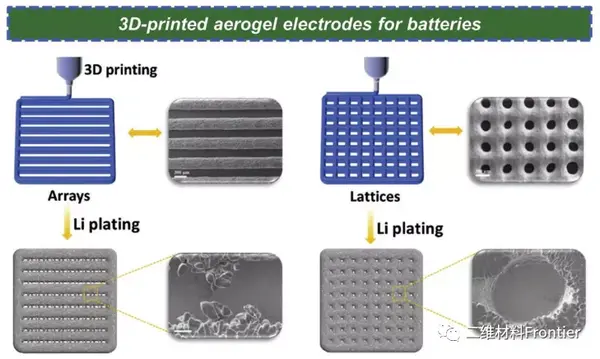

Figure 4.3D printed MXene array and lattice diagram.

Figure 5. The diversity and applications of additive manufacturing materials for aerogels and porous scaffolds.

3. Full text summary

In summary, due to its extraordinary properties, aerogel is considered to be a material with extremely low thermal conductivity, modulus, sound velocity, refractive index, dielectric constant, high specific surface area, and adjustable density. In this review, the author gives us an overview of the details of the 3D printing process of aerogels for various applications, including electrochemical energy storage, triboelectric nanogenerators, sensors, actuators, biomedical equipment, etc. Research on the development of 3D printed aerogel functional devices is still under development. Compared with aerogels manufactured by traditional manufacturing methods, the range of materials used in 3D printing aerogels needs to be further improved. Especially for ceramics and metals, different types of materials need to be explored before 3D printing aerogels can be widely accepted by research.

Article link:

https://doi.org/10.1002/adfm.202103410

This information is sourced from the Internet for academic exchanges only. If there is any infringement, please contact us to delete it immediately.