已传文件:photo/1631586161.png

Article information

The latest development of two-dimensional MXenes: preparation, intercalation and its application in flexible devices

First author: Xu Jinxin, Peng Ting Corresponding author: Shi Shengwei, Yu Huangzhong, Chen Bing Unit: Wuhan Institute of Technology, South China University of Technology, Institute of Precision Measurement Science and Technology Innovation, Chinese Academy of Sciences

Research Background

The two-dimensional material MXene has received extensive attention since it was discovered in Derexl University in 2011 due to its unique structure and excellent performance. The preparation of MXene materials mostly comes from the etching of the MAX phase of its precursor, where M represents the transition metal element in the periodic table, A is the main group element, generally Al or Si, and X is C or N. Thanks to the excellent properties of MXene in electronics, optics, biocompatibility, etc., it has very mature applications in many fields such as energy storage, electromagnetic shielding, sensing, and biomedical materials. In addition, the MXene material family is rich in variety. After chemical etching, the surface will contain abundant surface groups. After post-treatment, the surface groups can be controlled and the material properties can be diversified. Therefore, MXene is an important research direction in the field of two-dimensional materials. This article summarizes the development of the synthetic route of MXene in the past 10 years, briefly explains the intercalation method of MXene, and discusses the application of MXene in flexible devices.

Article Introduction

Based on this, Professor Shi Shengwei from Wuhan Institute of Technology, Associate Researcher Chen Bing from the Institute of Precision Measurement Science and Technology Innovation of the Chinese Academy of Sciences, and Professor Yu Huangzhong from South China University of Technology, published a title in the internationally renowned journal Journal of Materials Chemistry A. A review paper for Recent Advances in 2D MXenes: Preparation, Intercalation and Applications in Flexible Devices.This paper mainly introduces the development process of MXene synthesis methods and briefly analyzes the internal mechanism of these methods, gives an overview of the intercalation principle of MXene and the use of intercalation agents, and discusses in detail the two-dimensional MXene. The application of materials in the field of flexible devices, and prospects for the future development trend of MXene two-dimensional materials.

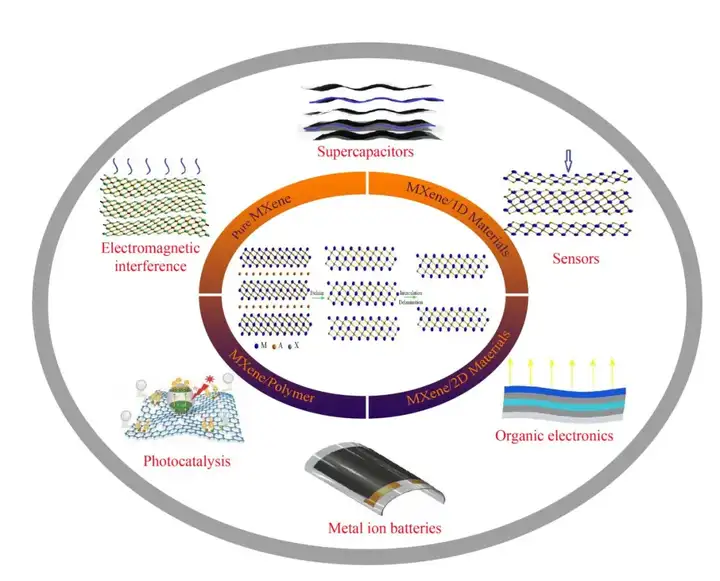

Figure 1 Synthetic route of MXene and its application in the field of flexible devices

Highlights of this article

Key point 1: Synthesis method of MXene material

The synthesis of MXene is mainly derived from the etching of its precursor MAX phase, and the two-dimensional layered MXene material is prepared by selectively etching away the A-layer elements. At present, there are various synthetic routes for MXene. Initially, it was etched with hydrofluoric acid to obtain a two-dimensional MXene with a clear accordion morphology. However, the use of hydrofluoric acid is dangerous in experimental operations. Therefore, a series of solution synthesis methods based on fluorine-based etching have been developed afterwards. Among them, the most widely used etching methods are LiF and HCl routes. In addition to fluorine-based etching, a fluorine-free etching method-Lewis acid molten salt synthesis method can achieve the etching of the MAX phase, and it is very valuable that this method can achieve the control of its surface groups And adjustment is of great significance for expanding the application of MXene materials. In addition, the article introduces two methods for preparing MXene by solid-state etching of MAX phase based on physical methods, UV-induced selective etching of Mo2Ga2C to prepare Mo2C and thermal reduction of Ti2SC to prepare Ti2C, which are a meaningful attempt in the synthesis of MXene. The reaction temperature of different synthetic routes and the influence of different methods on the surface groups of MXene are summarized in this article.

Key point 2: Intercalation treatment after MXene etching

After selectively etching away the elements of the A layer in the MAX phase, in order to obtain a larger layer spacing and increase the yield of MXene, it is very necessary to perform intercalation treatment. This article summarizes the commonly used intercalation methods used in past experiments, summarizes the chemical reagents and cations used in the intercalation process, and gives the effect of each method on the spacing of MXene layers. Large interlayer spacing is very important for improving the optical properties of MXene and ion transport in the electrochemical field. Not only can the interlayer spacing be expanded during the intercalation process, but some methods can also realize the functionalization of MXene surface groups. Therefore, the research on intercalation method is also a focus of research in MXene.

Key point 3: Application of MXene in flexible devices

MXene material itself has many excellent properties. The self-supporting film through vacuum filtration has good conductivity and excellent flexibility. The film can be easily bent and twisted. The article introduces the advantages of MXene in flexible devices. A series of applications. Pure MXene material can be used as a flexible electrode material in supercapacitors, sensors, and flexible organic light-emitting diodes. The combination of MXene and other materials also shows good flexibility, such as the combination with silver nanowires as AC electroluminescence The devices and electromagnetic shielding composite materials exhibit stable luminous efficiency and ultra-high electromagnetic shielding efficiency. The composite with carbon materials such as reduced graphene oxide and carbon nanotubes is used as a flexible electrode in supercapacitors, indicating that the addition of MXene makes the electrode flexible to a certain degree and also shows that it can further improve the charge storage capacity; and polyvinyl alcohol The composite of polymer materials such as PVA and polydimethylsiloxane PDMS guarantees the flexibility of the composite material and gives the material conductivity, so that it can be used as a piezoelectric sensor to detect human activities. In short, both pure MXene materials and MXene-based composite materials are widely used in flexible devices.

Point Four: Looking Forward

After ten years of development, the types of MXene materials have continued to grow, and MXene materials suitable for different fields have been successfully prepared. However, finding a universal, simple and environmentally friendly synthesis method is still the goal pursued. At present, the most researched and first discovered MXene is a material with Ti3C2Tx structure. The reason is that the conductivity of Ti3C2Tx is high and the synthesis process is mature. Previous studies have shown that the types of MXene materials are very rich. Explore more and develop more MXene materials. The application scenario is a focus of future research. Another very important thing is that the regulation of the surface groups of MXene is the key to adjusting its properties. The surface groups have obvious effects on the structure, electronics, dispersibility and other properties. The ability to effectively control the surface groups of MXene can improve its application efficiency. It is beneficial to develop new application scenarios. In short, the understanding of MXene materials is still insufficient, and more research workers are needed to devote themselves to it.

Recent Advances in 2D MXenes: Preparation, Intercalation and Applications in Flexible Deviceshttps://pubs.rsc.org/en/Content/ArticleLanding/2021/TA/D1TA03070A#!divAbstract

This information is sourced from the Internet for academic exchanges. If there is any infringement, please contact us to delete it immediately