ÒÑ´«Îļþ£ºphoto/2019861599271.png

Microfluidics is an emerging interdisciplinary subject involving chemistry, fluid mechanics, materials science, and biomedicine. Microfluidic technology has a good application prospect in the fields of biological detection, chemical analysis and emulsion synthesis. The design of microfluidic devices often involves the understanding of multiple physical processes, including the flow field distribution of fluids in a particular channel, the control of the flow of immiscible two-phase fluids, and the transport of solutes in microfluidic channels. Transport and diffusion, and the response of a fluid to an external field such as an electric field, a light field, or a sound field. Understanding the interaction of these physical factors is the key to designing microfluidic devices. On the other hand, since the preparation of the microfluidic chip often requires the use of a micro-nano process, it takes a lot of time and effort to prepare a microfluidic device. Therefore, before the microfluidic device is prepared experimentally, it is necessary to improve the scientific research efficiency by theoretically modeling and simulating the design. In addition, the addition of theoretical simulations in the paper can also improve the quality of the article and help impact high-end journals.

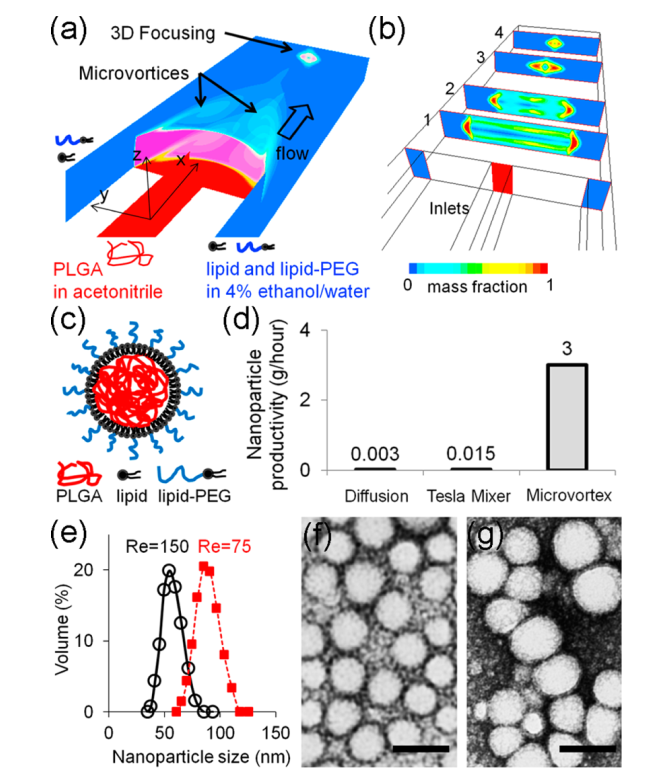

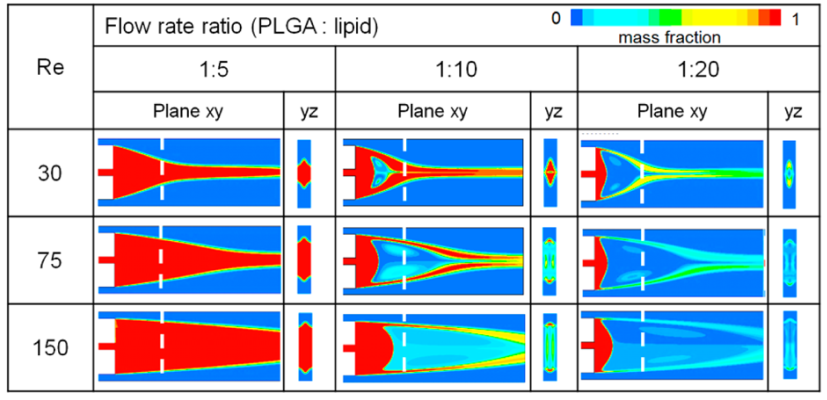

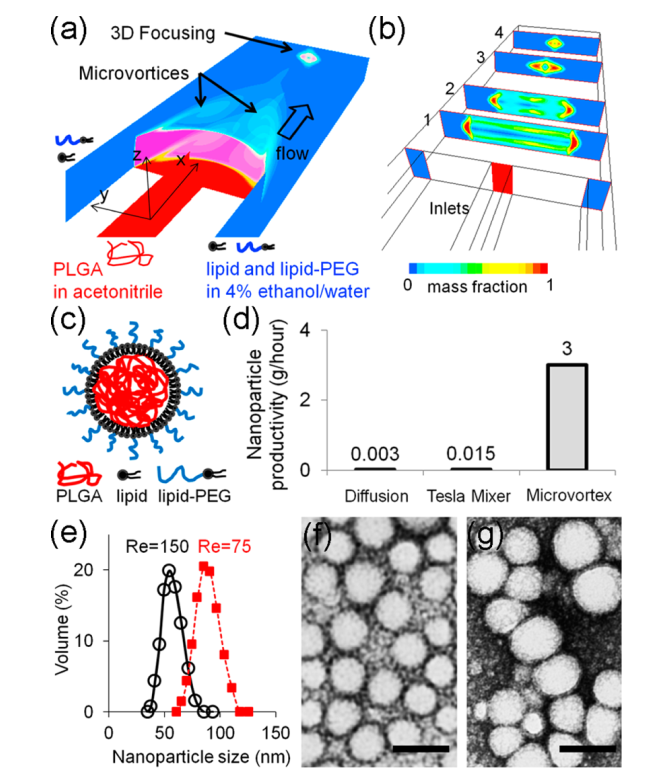

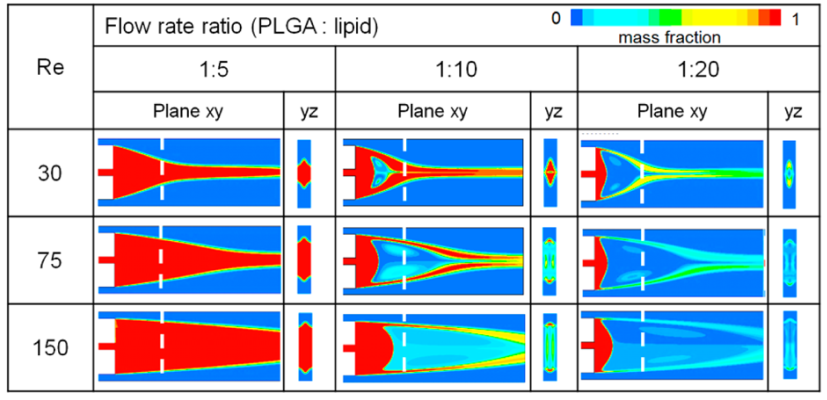

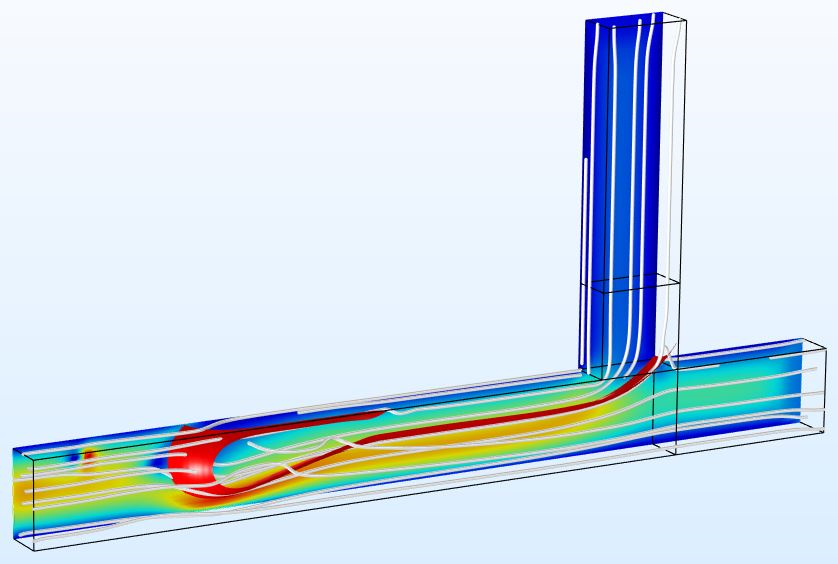

A research paper published on Nano Lett. designed a microfluidic device for the preparation of nano-latex particles. The two reactant solutions flow in from the red and blue inlets in the figure below, respectively, and create eddy currents in the channels after inflow. The intensity and size of the eddy currents affect the mixing and reaction of the two reactants, resulting in nanoparticles of different particle sizes. The simulation can simulate and control the size and shape of the vorticity. And through the simulation, the scientific problems are well explained.

£¨Nano Lett. 2012, 12, 3587.£©

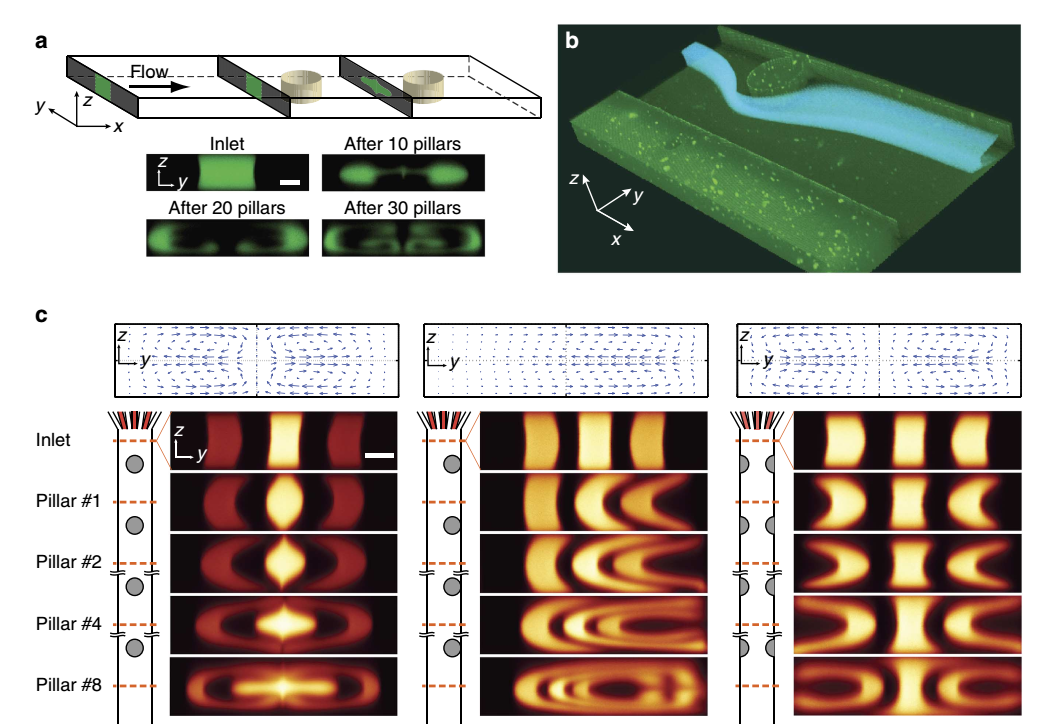

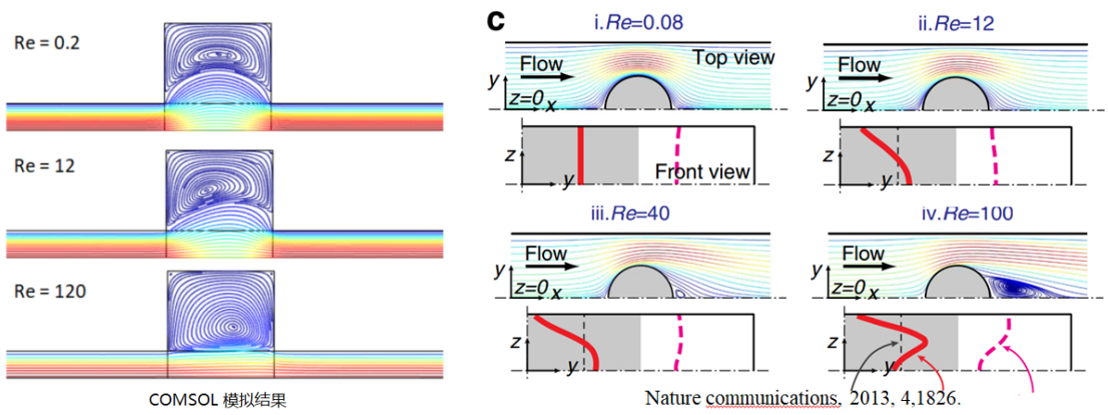

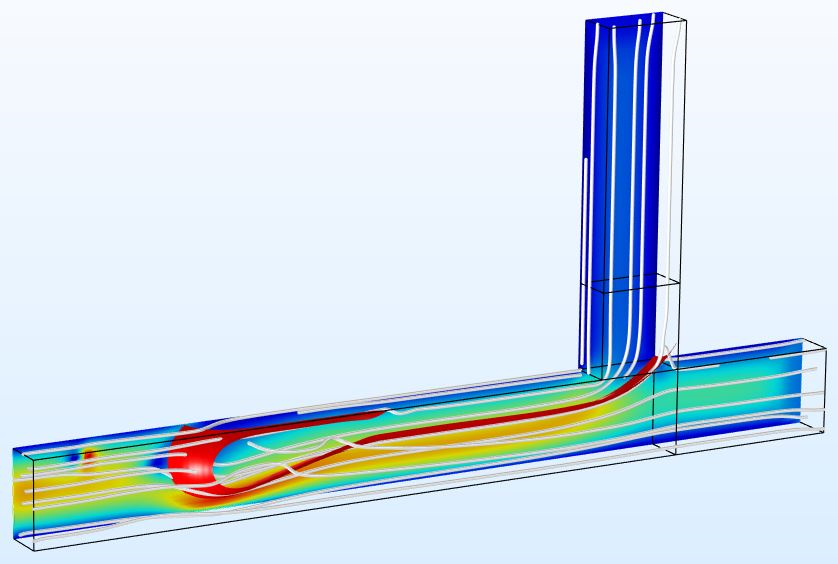

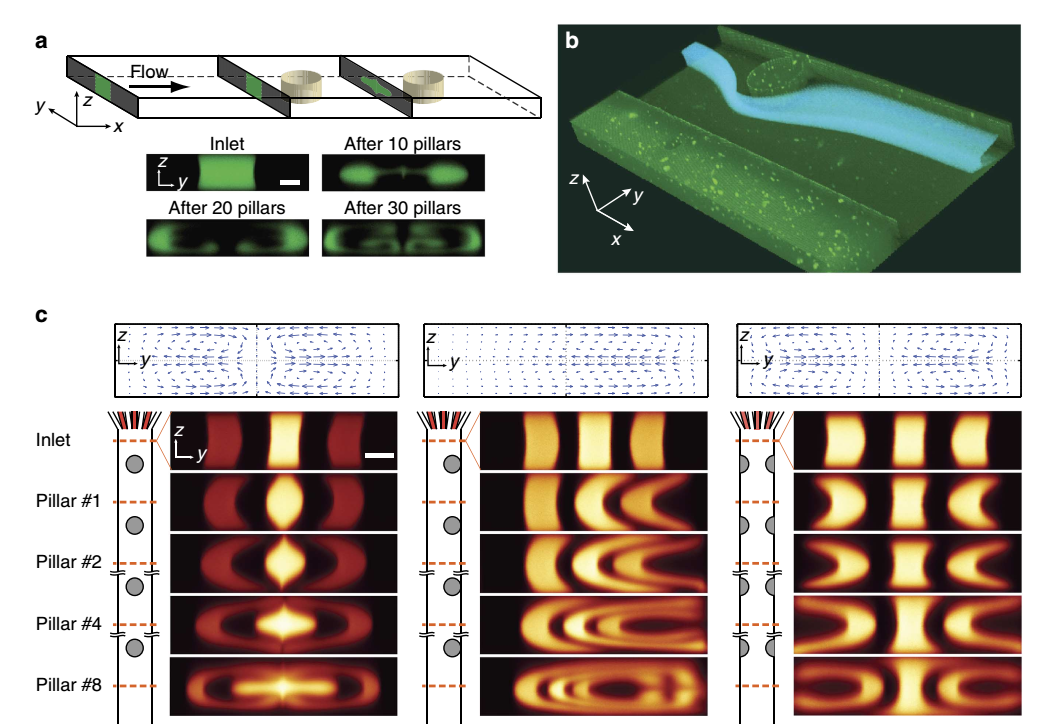

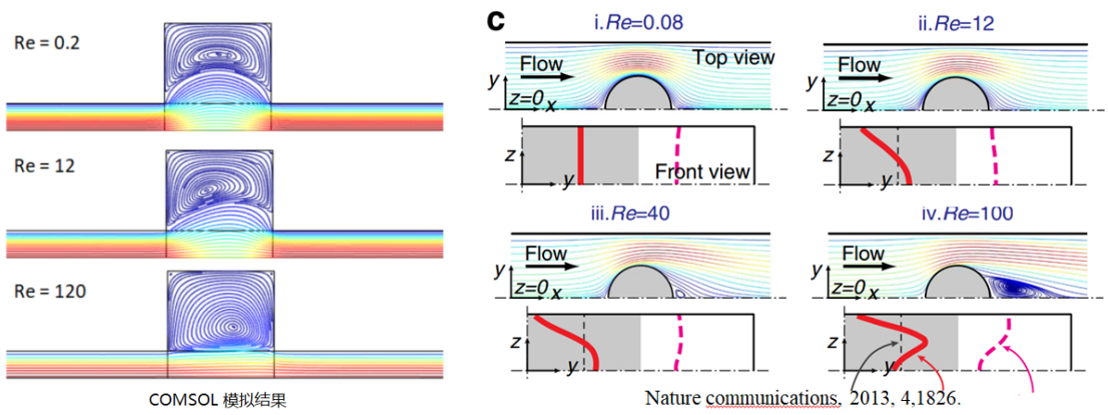

Another paper published in Nature Communications studied the effects of a turbulent obstacle in a microfluidic channel on fluid behavior through simulation. The channel inlet has a partial streamline marked with green fluorescence in the middle, which forms a diversified shape after passing through the obstacle. These topography are related to the location of the obstacle on the one hand and the Reynolds coefficient of the fluid on the other hand. The simulation of the fluid is a good predictor of the evolution of the marked part and is in good agreement with the experimental results.

£¨Nature communications, 2013, 4,1826.£©

The simulations in the above high-end articles can all be implemented by COMSOL Multiphysics. COMSOLMultiphysics is a very flexible and easy-to-use finite element simulation software that makes it easy to simulate various physical problems in the field of microfluidics. At present, several hot research topics in the field of microfluidics and droplet hydrophobicity infiltration can be simulated by COMSOL Multiphysics. We can sum up, we can use COMSOL to solve the following major problems.

1. Relationship between eddy current formation and Reynolds coefficient

The magnitude of the Reynolds coefficient (Re) represents the ratio of fluid inertia and viscosity action. In the case where the structure of the microfluidic channel is constant, the fluid flow rate increases and the Reynolds coefficient increases accordingly. Through fluid dynamics simulation, we can accurately predict the morphology of eddy current formation under a certain Reynolds coefficient. Theoretical simulations can help us design and optimize the structure of the microfluidic channel to achieve the intended purpose. For example, this 2013 Nature Communications calculated the eddy current formation under different Reynolds coefficients.

2. Electroosmotic flow and diffusion of matter in microfluidic channels

Due to the small scale of microfluidic devices, the use of an external electric field to manipulate fluid motion is currently the main method. Electroosmosis is a commonly used method in which an applied electric field is applied to a charged surface (the inner wall of a glass capillary) or both ends of a porous solid medium, and the solution in the driving channel flows at a fixed speed. The flow velocity is related to the wall surface potential and the applied electric field strength. COMSOL Multiphysics has built-in electroosmotic flow boundary conditions that make it easy to simulate electroosmotic flow problems. The following case analyzes the transport and diffusion of solute in a U-shaped electroosmotic flow device. The geometric calculation of the fluid passage bend is simulated using simulation calculations to minimize the dispersion of solute caused by bending.

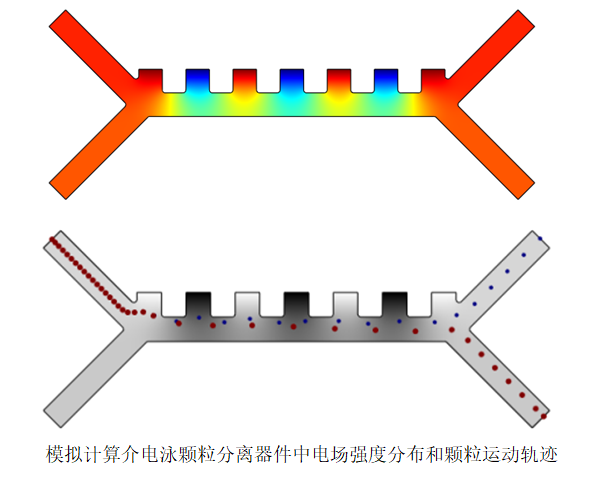

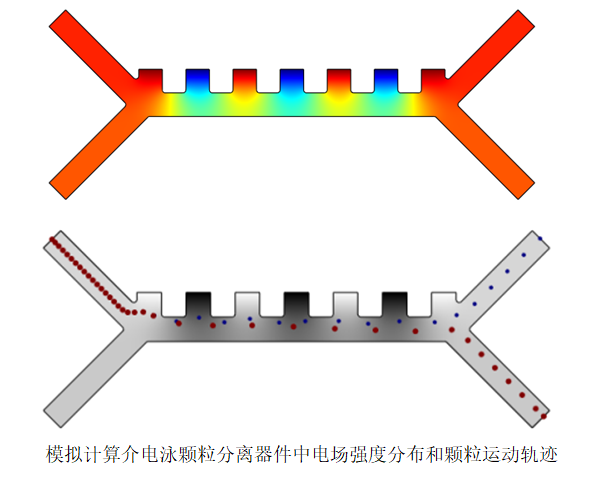

3. Dielectrophoresis

Dielectrophoresis is the force caused by the difference in dielectric constant between suspended particles and solvent under the action of an external electric field. The dielectrophoretic force pulls particles with a dielectric constant less than the solvent toward a place where the electric field strength is low. In addition, the size of the dielectrophoretic force is also related to the particle radius, so dielectrophoresis is often used to separate particles or cells of different sizes. To design a dielectrophoretic device, it is necessary to control the electric field distribution, flow field, and calculate the trajectory of different particles in the device. This is a complex problem involving multiple physical processes, but COMSOL Multiphysics modeling and calculation can fully simulate the dielectrophoretic device, helping us to design and optimize efficient dielectrophoresis devices.

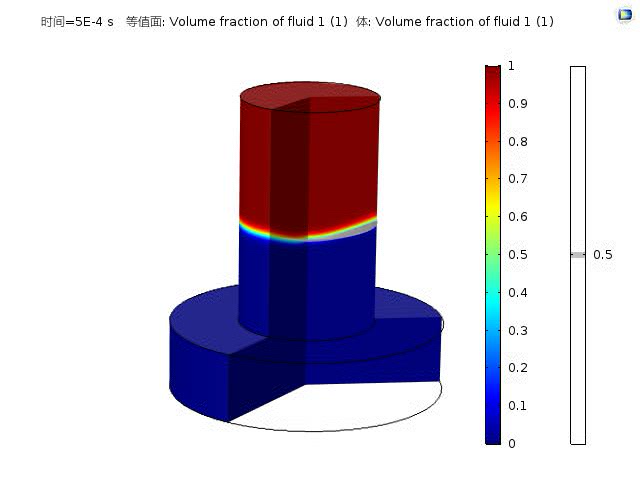

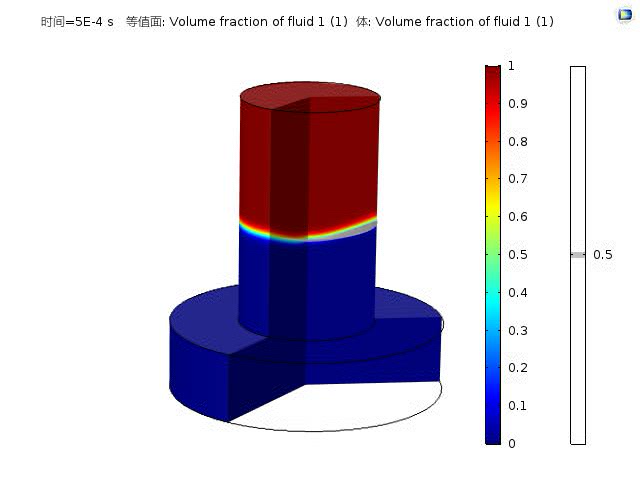

4. Two-phase flow

The T-tube utilizes two immiscible liquids to produce microdroplets of various sizes, but the size of the droplet formation is related to the flow velocity of both inlets and the surface tension. The two-phase flow simulation method can accurately simulate the formation of droplets in T-tubes, as well as factors such as fluid flow and additive chemicals, and how they affect droplet size and formation.

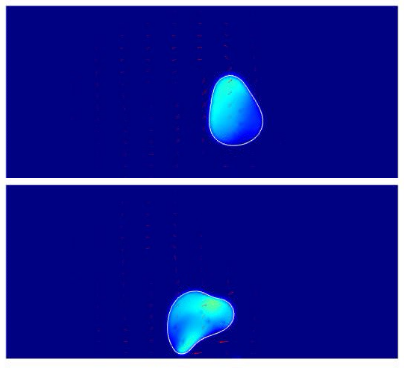

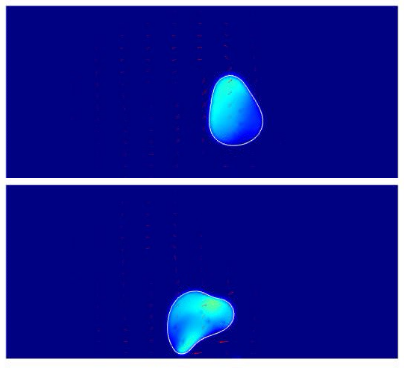

5. Various pro-hydrophobic and invasive phenomena

Under the action of the hydrophobicity of the solid surface and the surface tension of the droplets, the droplets undergo various infiltration phenomena. Many dynamic droplets are very infiltrated and often require a high speed camera to capture. On the other hand, we can also theoretically calculate the motion of the droplet by COMSOL. For example, the ascending process of water in the capillary and the process of the droplets bouncing on the hydrophobic surface are shown in the figure below.

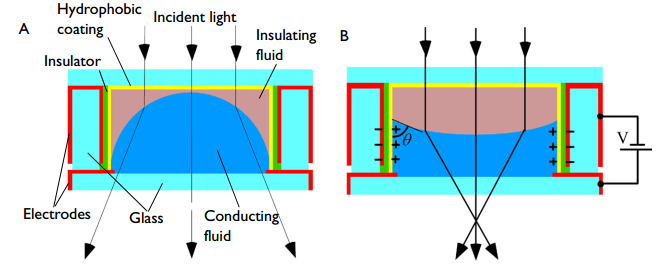

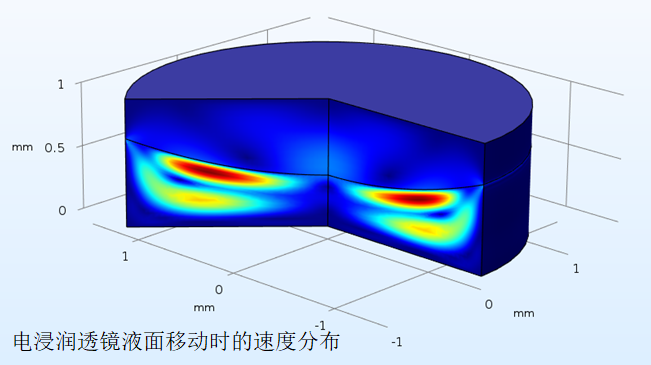

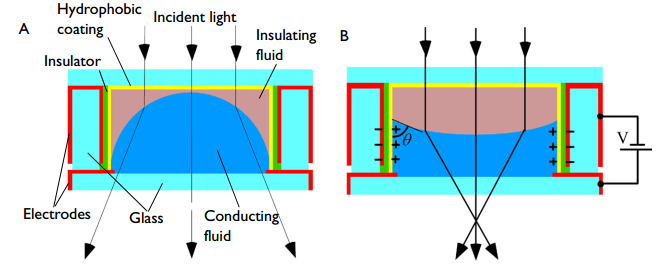

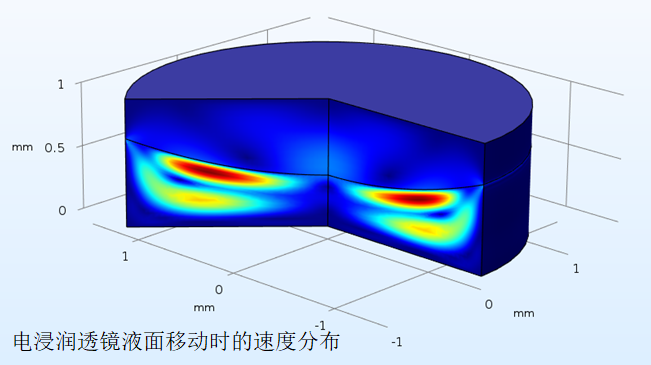

6. Electrowetting

Electrowetting is the manipulation of the contact angle of a droplet on a solid surface by an applied electric field. On an otherwise hydrophobic surface, the droplets have a large contact angle, and when a certain voltage is applied, the contact angle becomes small. By the design of the electrodes and the application of an electric field to the asymmetry, the movement of the droplets can be manipulated. Another application scenario for electrowetting is to make a zoom lens that adjusts the curvature of the lens by voltage adjustment of the curvature of the surface of the droplet.

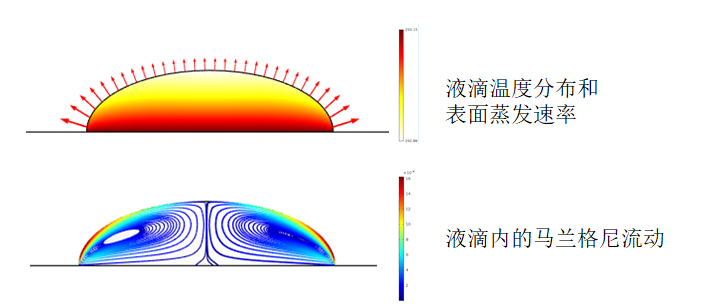

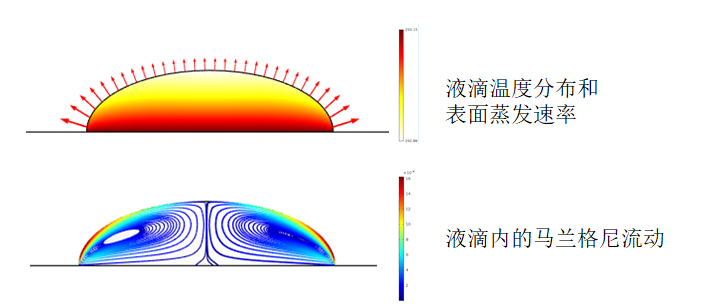

7.Marangoni effect

The Marangoni effect is the fluid motion caused by the liquid surface tension gradient. The Marangani effect during droplet evaporation is a very classic field of fluid mechanics research. The mechanism of a Marangoni effect in droplet evaporation is as follows: the endothermic effect of evaporation evaporation causes the surface temperature of the droplet to decrease, and the evaporation rate at different positions on the surface of the droplet is different, resulting in different surface temperatures and temperature gradients. The gradient of the surface tension is created to form the Marangani effect. Modeling with COMSOL Multiphysics allows simultaneous calculation of fluid flow caused by evaporation, heat transfer and surface tension gradients.

summary

In the field of microfluidics and pro-hydrophobic infiltration, many processes can be simulated. Simulation can help optimize device design, help us analyze and understand various physical processes, improve research efficiency, and help create quality scientific research results. Mastering the simulation skills in microfluidics can help my research in many ways.