已传文件:photo/1766544328.png

Featured in this article

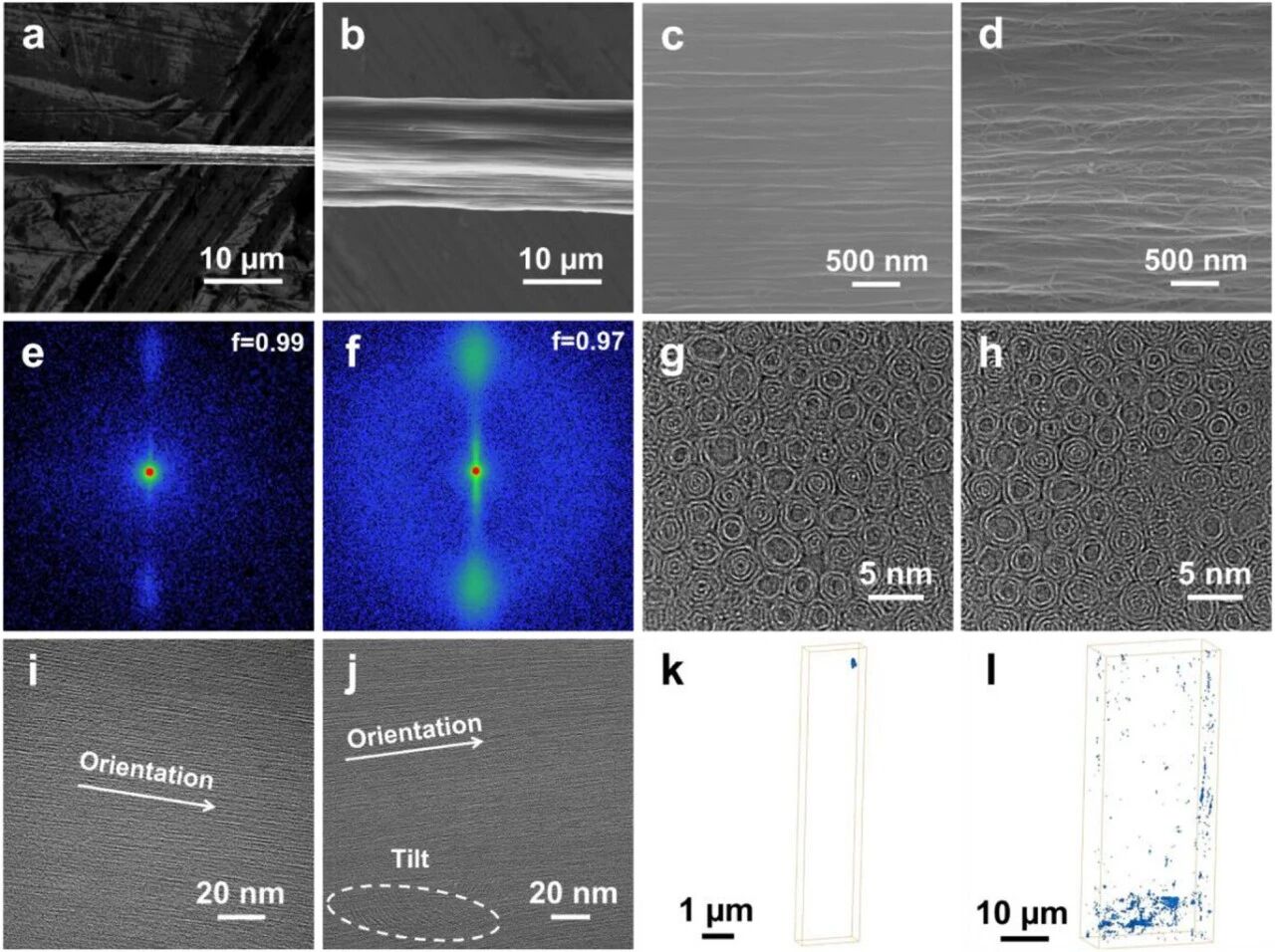

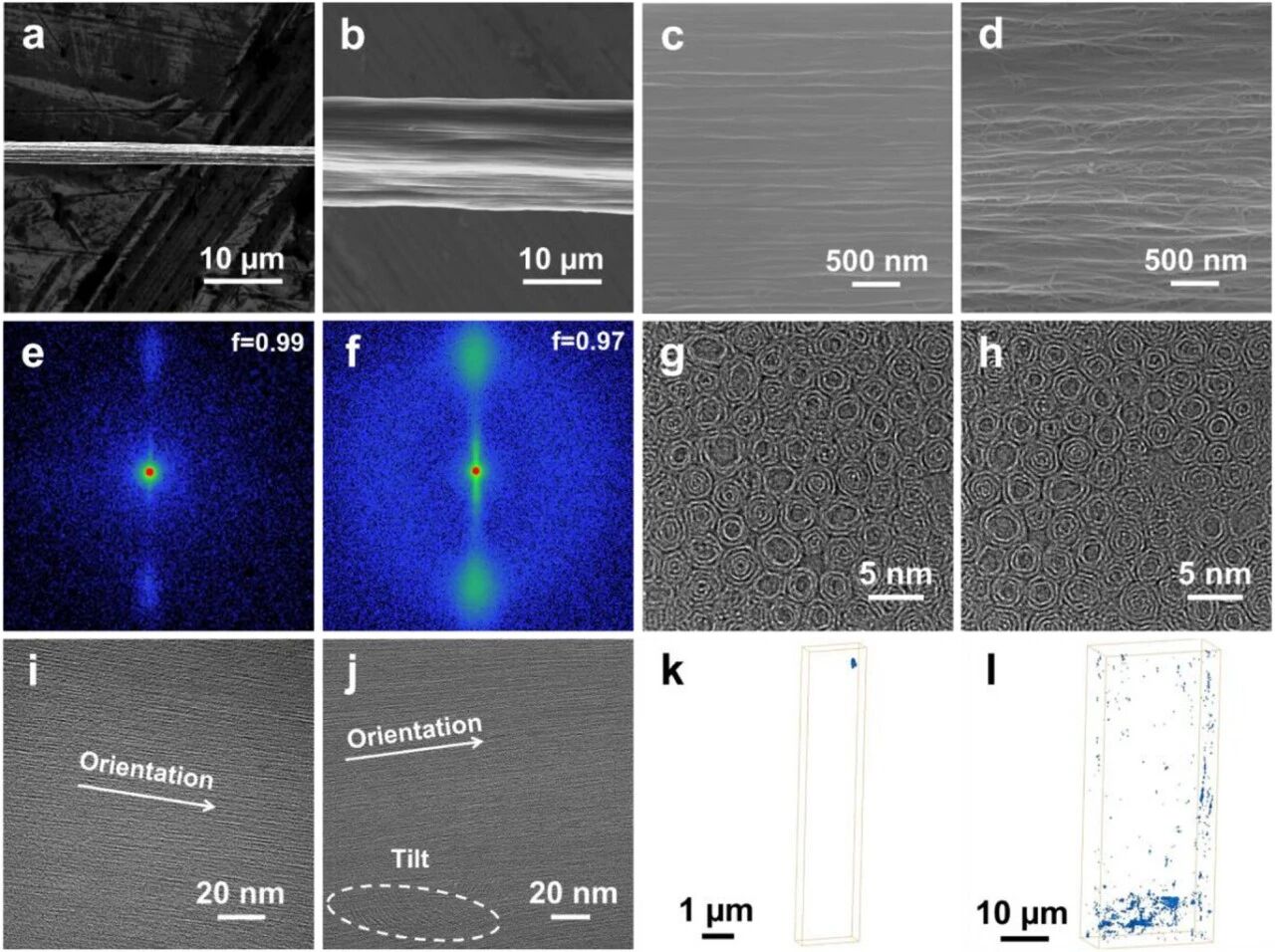

Ultrathin carbon nanotube fibers (CNTFs) need to have high electrical conductivity and current-carrying capacity to be used in wearable electronic devices. However, spinning ultrathin CNTFs is very challenging due to the core-shell structure formed in the normal acetone coagulation bath used during wet spinning, which limits the applicable draw ratio.Here, by using high aspect ratio double-walled carbon nanotubes as the raw material and water as the coagulation bath, this limitation was overcome, increasing the draw ratio from 1.6 to 54.6. As a result, ultrathin carbon nanotube fibers (UCNTFs) with an equivalent diameter of 2.68 µm were obtained for the first time, approximately six times thinner than the fibers spun in acetone coagulation (A-CNTFs).UCNTFs exhibit a high Herman orientation factor of 0.99, low residual chlorosulfonic acid (CSA) content, excellent thermal stability, and a record-high current-carrying capacity of 1.52 × 10^9 A m−2. This outstanding electrical performance is attributed to their ultra-thin diameter and reduced CSA doping, which allow for rapid heat dissipation during Joule heating.

Original link

Original link

Ultrathin Carbon Nanotube Fibers with a Record High Ampacity Fabricated Using a Water Coagulation Bath

Advanced Functional Materials ( IF 19 )

Pub Date : 2025-10-17

DOI: 10.1002/adfm.202518867

Chun‐Yang Sun, Hao‐Zike Wang, Zhao‐Qing Gao, Peng‐Xiang Hou, Chao Shi, Yan Liang, Shao‐Gang Wang, Chang Liu, Hui‐Ming Cheng