introduction

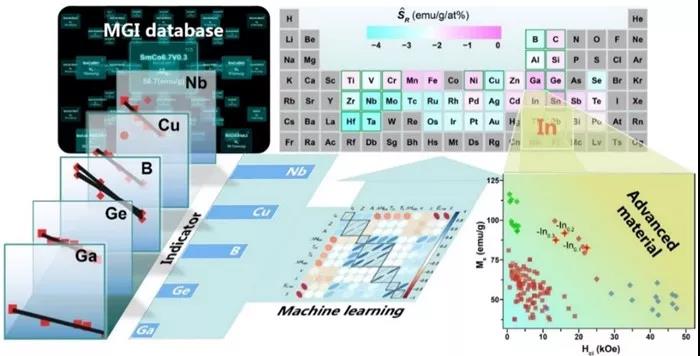

Based on the construction and development of a database of rare earth elements and Sm-Co based alloy systems over the years, recently, the team of Professor Xiaoyan Song from Beijing University of Technology has made new breakthroughs in data-driven new material design. "Mining for Advanced Magnets" was published in Chemistry of Materials. The first author of the thesis is Liu Dong, a doctoral student. This work is based on the Sm-Co-based multi-alloy database and saturation magnetization data set, and combines data mining and machine learning to screen saturated magnetization-friendly doping elements, which significantly promotes the development of high-performance new materials. This method of quickly and accurately screening additional elements in a wide range can be popularized and applied to the composition design of a variety of materials with adjustable properties.

Database construction background

The research team constructed a database of rare earth elemental and Sm-Co compounds between 2006 and 2013 and developed into a rare earth basic data resource node in China‘s material science data sharing network. Taking this as the research background, in recent years, the team took the high-temperature permanent magnet alloy representative system Sm-Co-based multiple alloy as an example, and built a dedicated database for data-driven material design. The data has been highly structured and can meet the needs of deep-based information. Data retrieval, data structure conversion, and special data set extraction for material design. The research reported in this paper is one of the material design goals based on this special database.

Data-driven material design

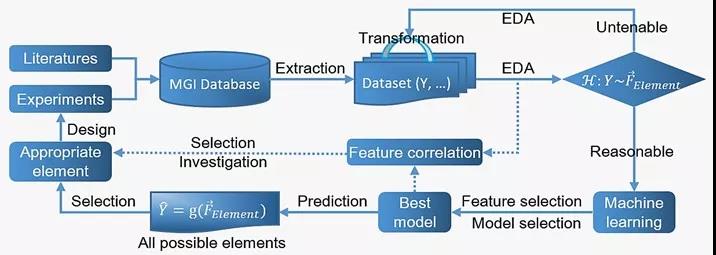

The method of adding element screening in this paper is proposed when mining saturation magnetization-related data in the database. In the development of magnetic materials, it has been common practice to avoid those elements that are not conducive to saturation magnetization. In this work, the Sm-Co based alloy saturation magnetization data set is extracted from the constructed special database to carry out data-driven material design and development.

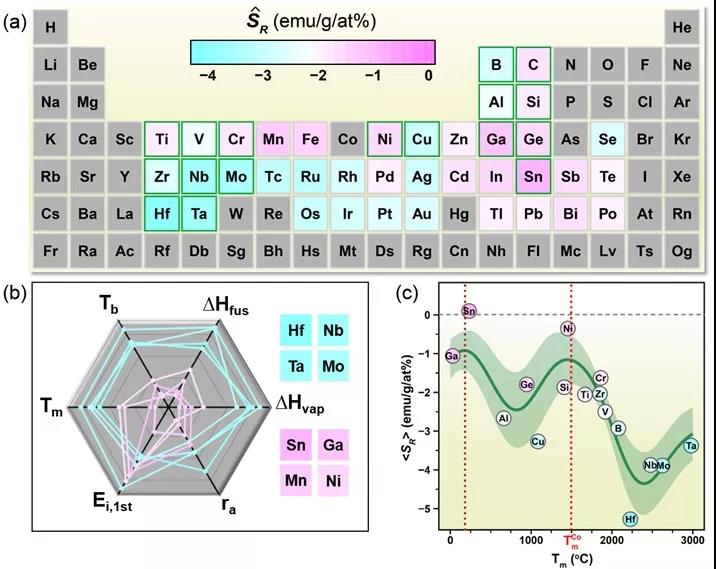

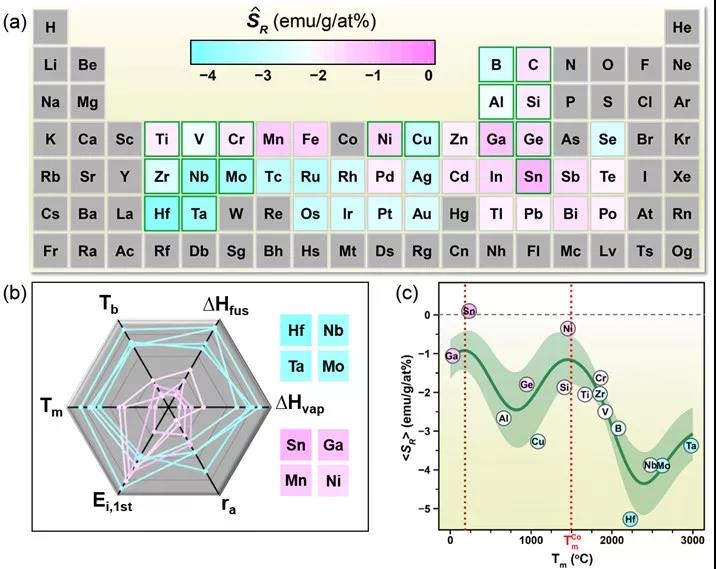

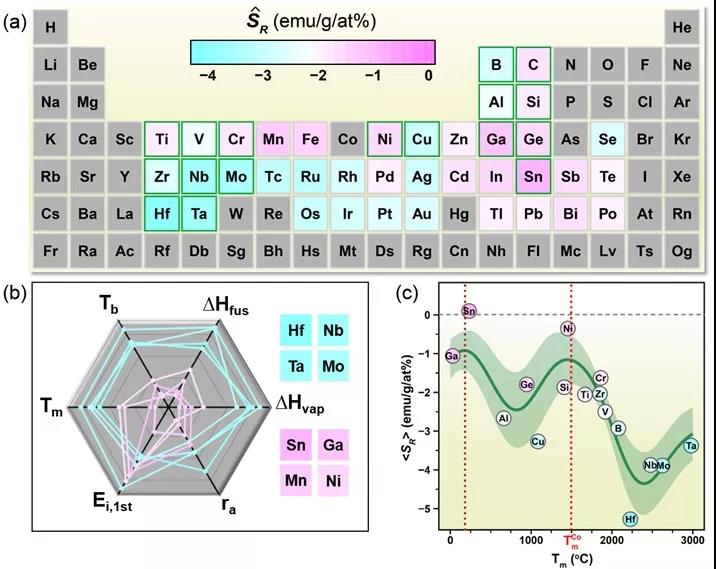

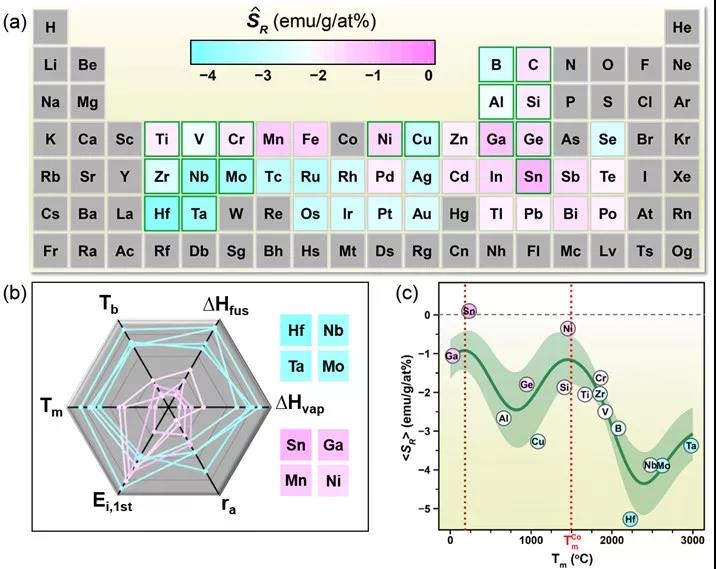

Through group data identification, it was found that the group linear regression parameter is an important feature used to analyze the various influencing factors of saturation magnetization, and then an index for evaluating the effect of doping elements on the saturation magnetization of the alloy (herein referred to as SR) was proposed. The research goals focus on the prediction of saturation magnetization to the screening of doped elements. The correlation between the SR of the known doping element and the typical characteristics of the doping element was established through machine learning, and the influence of the doping element on the saturation magnetization of the Sm-Co-based alloy was evaluated over a wide range of the periodic table.

(Figure 1. Predicted effects of doping elements on the saturation magnetization of Sm-Co based alloys and their relationship with known characteristics of the elements)

(Figure 1. Predicted effects of doping elements on the saturation magnetization of Sm-Co based alloys and their relationship with known characteristics of the elements)

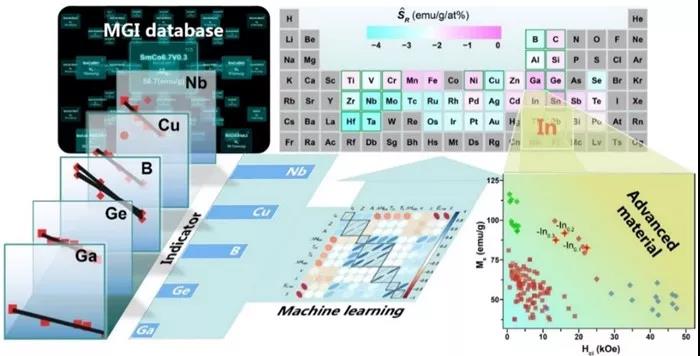

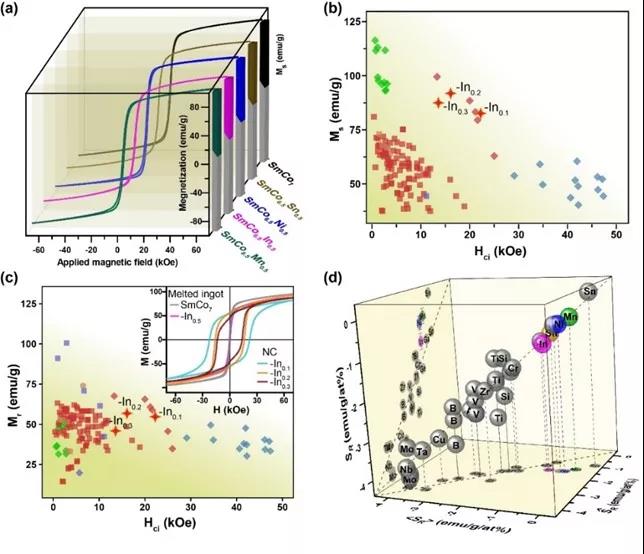

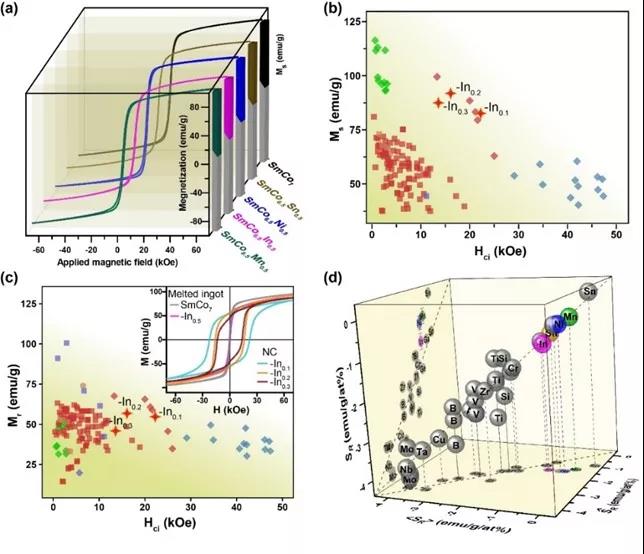

According to the above-discovered rules, the doping elements can be screened comprehensively and accurately, and then the component design and experimental preparation can be efficiently guided. Using the preferred elements for experiments and doping Sm-Co-based alloys, the actual results show that the preferred elements can maintain the same high saturation magnetization as the corresponding Sm-Co binary alloys, and are in good agreement with the predicted results. It shows that these doping elements have very important utilization value and development potential. Furthermore, by combining process design and microstructure optimization, a number of new Sm-Co based permanent magnet alloys with superior comprehensive magnetic properties have been developed.

(Figure 2. Composition design and experimental preparation with the preferred doping elements, verified the prediction results, and improved the comprehensive magnetic performance to an advanced level)

(Figure 2. Composition design and experimental preparation with the preferred doping elements, verified the prediction results, and improved the comprehensive magnetic performance to an advanced level)

Method applicability

The choice of added elements is a very important part of the material composition design process. However, the application scenarios of the selected elements are complex and changeable, and it is often difficult to find effective theories to guide them. The method established in this paper can be extended to the problem of element selection in various doping modifications. In these problems, there are often a lot of exploratory experimental or theoretical calculation data in the reported literature, but it is difficult to traverse all the elements due to the experimental period or experimental conditions. Use data transformation or visualization technology to conduct exploratory analysis on the established data set, find the parameters dominated by the element type, and use it as a quantitative (corresponding to regression algorithm) or qualitative (corresponding to classification algorithm) criterion for existing data Evaluation. Using machine learning to find the relationship between the parameter and the known attributes of the element, the parameter can be reasonably generalized to all available elements, thereby achieving the goal of filtering elements from a wider range. Further, by in-depth interpretation of the model by using feature screening or variable importance analysis, interpretive knowledge or rules can be obtained.

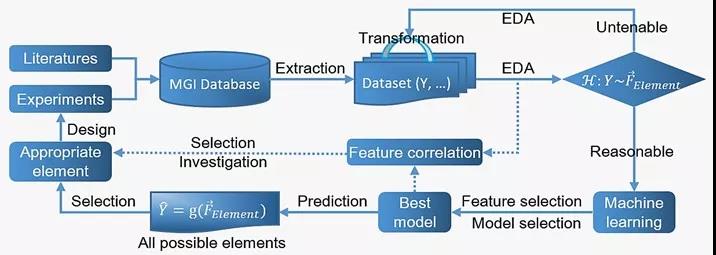

(Figure 3. Schematic diagram of a data-driven strategy for doping-modified material design)

Dedicated database application outlook

This paper is an example of building a data set, processing data, and combining machine learning techniques to accelerate material design starting from a dedicated database for data-driven materials design. As the amount of data increases and the quality improves, more and more research topics can be mined in the dedicated database, and the design and development of data-driven high-performance new materials for more topics will continue to advance and expand.

This research direction was supported by the national key research and development plan project "Special Database for Materials Genetic Engineering and Material Big Data Technology", the subject "Multi-scale high-throughput material calculation tool integration and unified interface development", and the National Outstanding Youth Science Foundation project.

Click for details to see the full text:

https://pubs.acs.org/doi/10.1021/acs.chemmater.9b03379

source? ——WeChat public: material person

(Figure 1. Predicted effects of doping elements on the saturation magnetization of Sm-Co based alloys and their relationship with known characteristics of the elements)

(Figure 1. Predicted effects of doping elements on the saturation magnetization of Sm-Co based alloys and their relationship with known characteristics of the elements)

(Figure 2. Composition design and experimental preparation with the preferred doping elements, verified the prediction results, and improved the comprehensive magnetic performance to an advanced level)

(Figure 2. Composition design and experimental preparation with the preferred doping elements, verified the prediction results, and improved the comprehensive magnetic performance to an advanced level)