【Research Background】

With the rapid development of electronic technology, flexible and wearable sensors have attracted wide interest. This is due to their wide application in various fields, especially in the field of intelligent robots. Among various sensors, such as gas and steam sensors, biosensors, strain and pressure sensors, pressure sensors have achieved remarkable results over the past decades. Piezoresistive pressure sensors can convert mechanical deformations into resistive signals and are shown in a variety of electronic applications including electronic skin, voice monitoring and personal activity recognition, portable medical diagnostics such as heartbeat, pulse wave, blood pressure and body temperature Great potential because of their fast frequency response, excellent stability and low manufacturing costs. However, due to the inherent rigidity of the sensing material and the viscoelasticity of the flexible substrate, the piezoresistive pressure sensor has shortcomings in terms of stretching, sensitivity and sensing range, which limits its application in flexible and wearable devices. In order to solve these problems, it can be achieved by designing some complex structures or changing the contact resistance between the material and the substrate. But these complex designs also make large-scale manufacturing difficult.

Because graphene has high electrical conductivity, good mechanical strength, and soft structure, many studies have focused on two-dimensional graphene sensing materials. Although graphene has high electrical conductivity, its inert surface chemistry limits its application on other smooth substrates. As an emerging two-dimensional material, MXene has great application potential in many aspects due to its unique structure and electronic properties and rich surface functional groups.

[Achievement Profile]

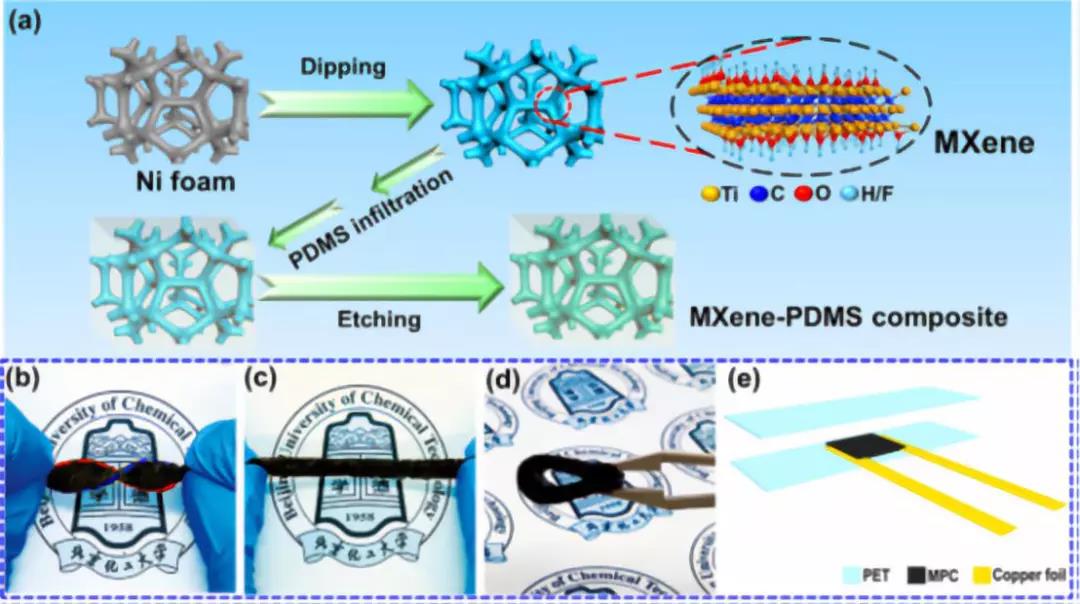

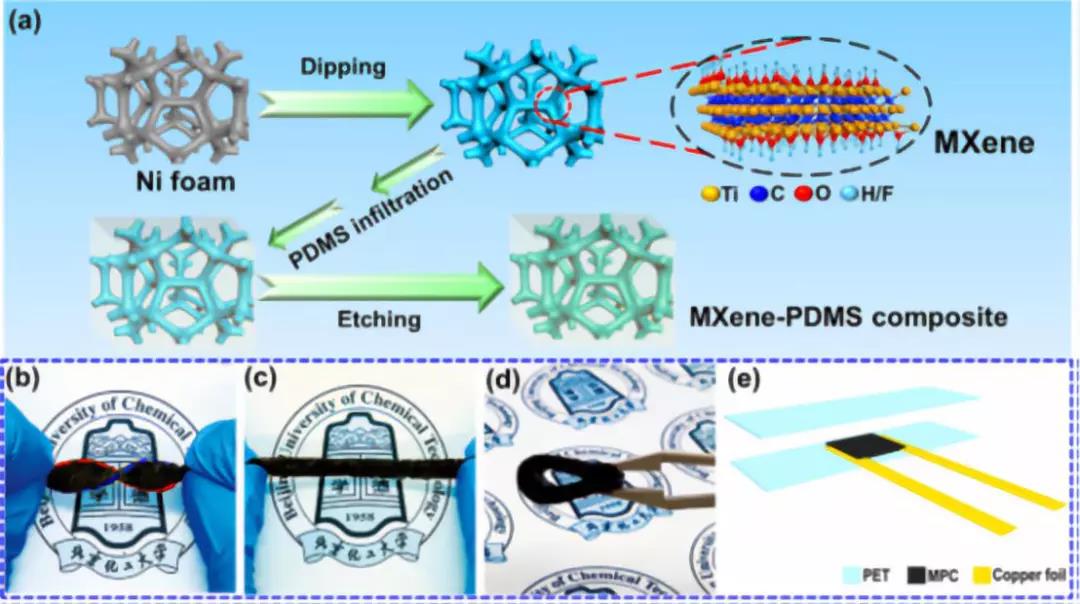

Recently, Professor Yu Zhongzhen of Beijing University of Chemical Technology published a research paper titled: Hollow-structured MXene-PDMS composites as flexible, wearable and highly bendable sensors with wide working range in the internationally renowned academic journal Journal of Colloid and Interface Science. Based on the hollow structure of MXene-PDMS composites (MPCs), a flexible piezoresistive pressure sensor with excellent bending stability was developed. The MXene flakes were deposited on the foam Ni frame by immersing the foam in an aqueous dispersion of MXene flakes. After the obtained MXene-deposited foam Ni is filled with PDMS to fix a 3D porous structure, the foamed Ni substrate is chemically etched to form a hollow structured MPC. As a flexible sensor, the MPC has satisfactory structural stability. And long-term reliability (1000 cycles), high sensitivity and large angle (0 ° –180 °) deformation capability. In addition, it can monitor subtle movements (swallowing, facial muscle movements, stereo and ultrasonic vibrations) and robust human movements (twisting fingers, bending, compression, wrist and neck movements), showing its application in wearable sensor applications. Great potential.

[Picture and text guide]

Figure 1. Schematic of the fabrication of a hollow structure MPC sensor.

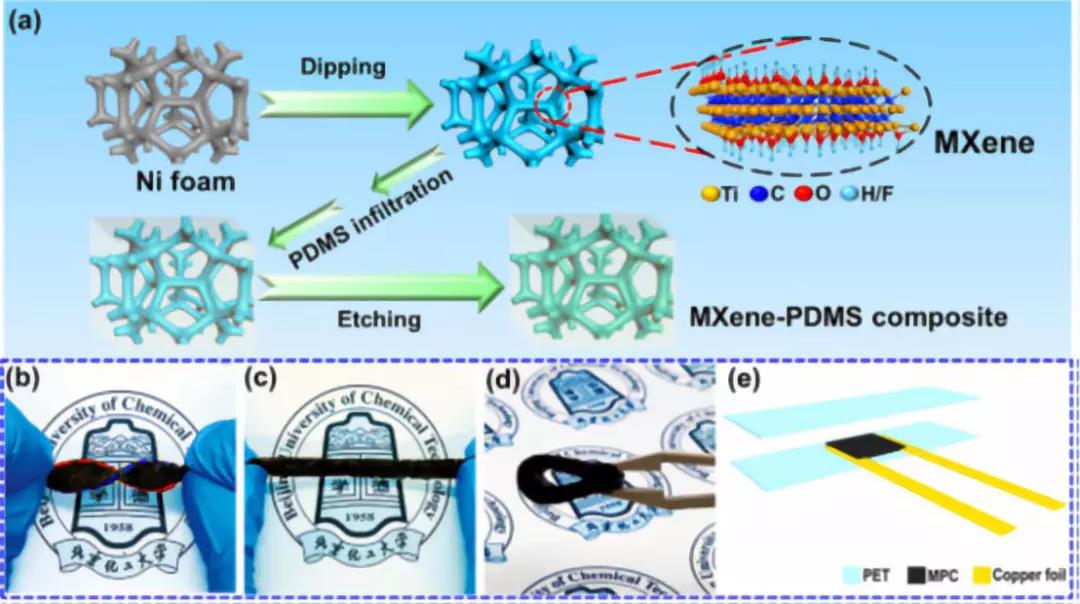

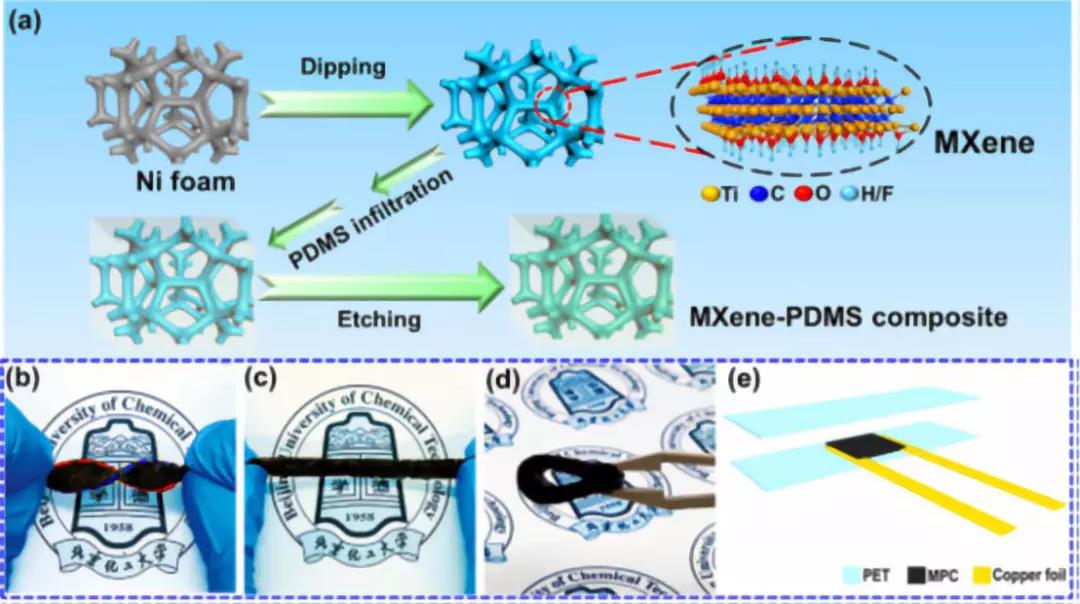

Figure 2. SEM and mapping images of MPC and related materials.

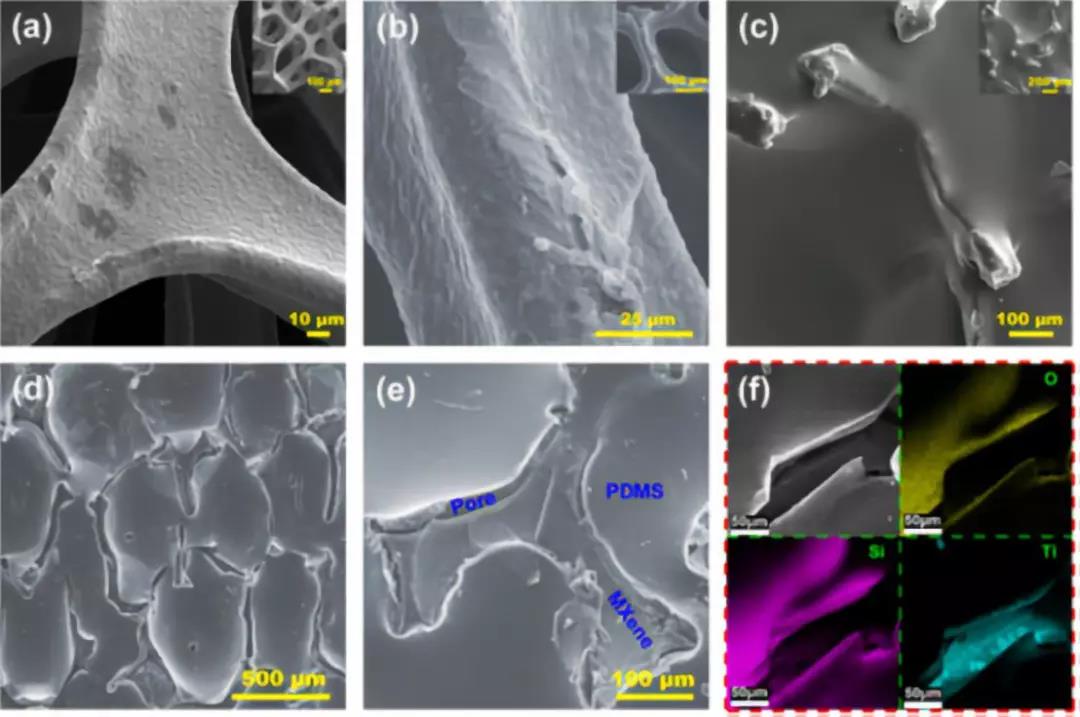

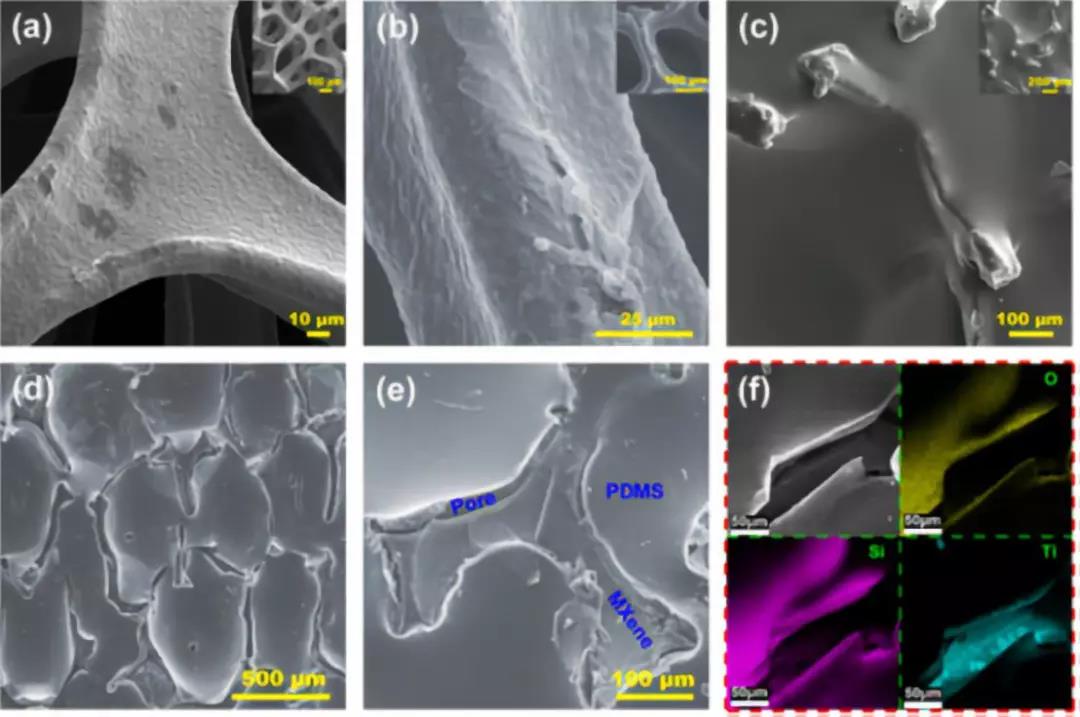

Figure 3. Effect of immersion time on MPC material performance and response time of MPC sensors.

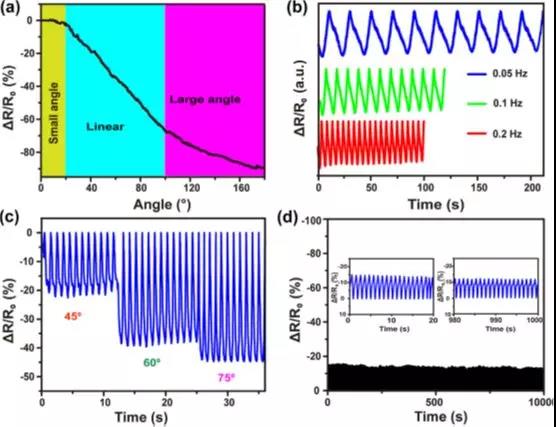

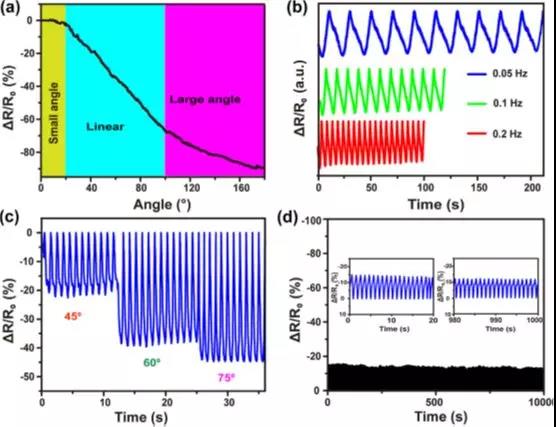

Figure 4. Sensing performance of an MPC bendable sensor.

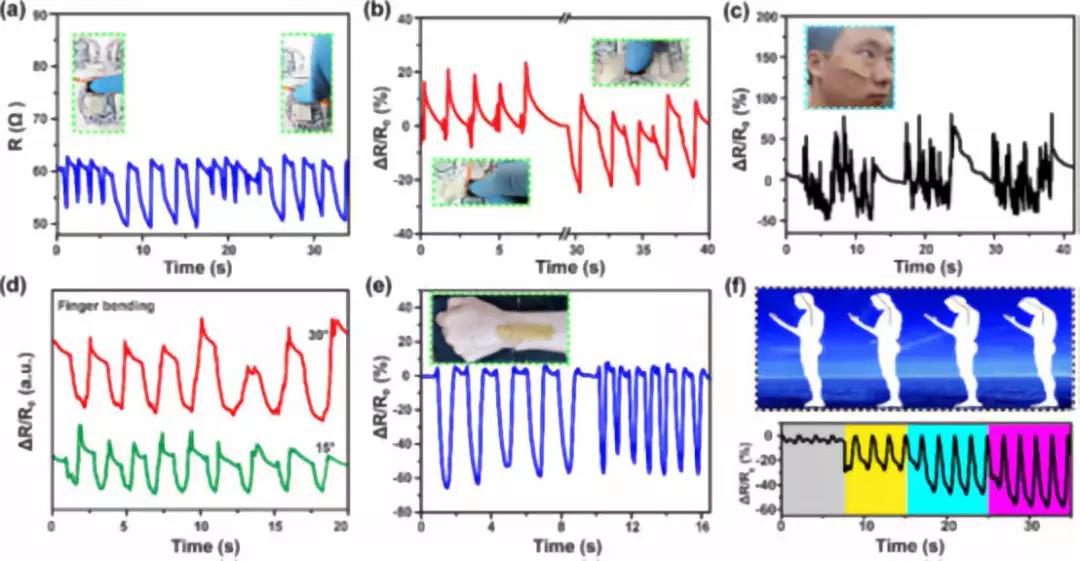

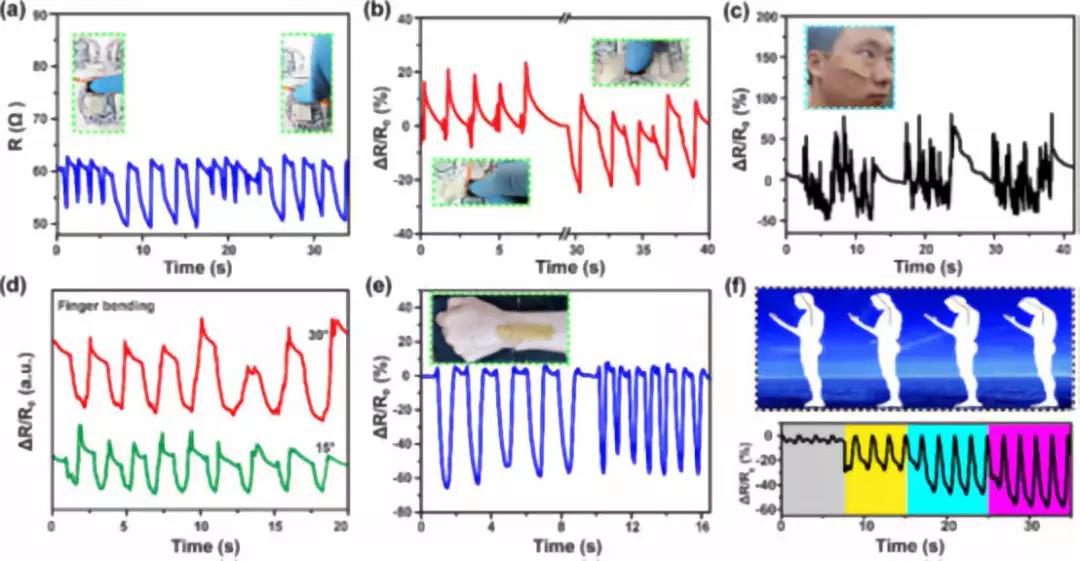

Figure 5. MPC flexible sensor detects human motion.

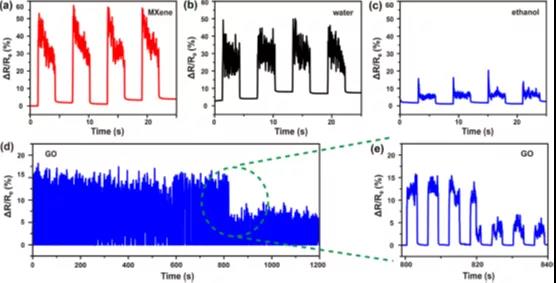

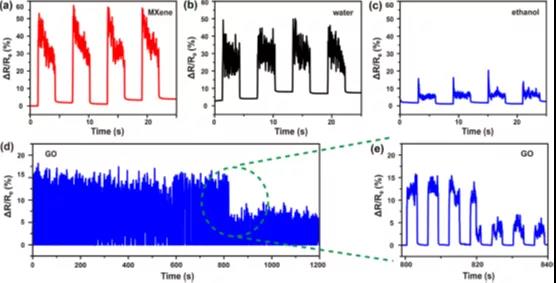

Figure 6. Real-time ultrasound performance characterization using a probe ultrasound system.

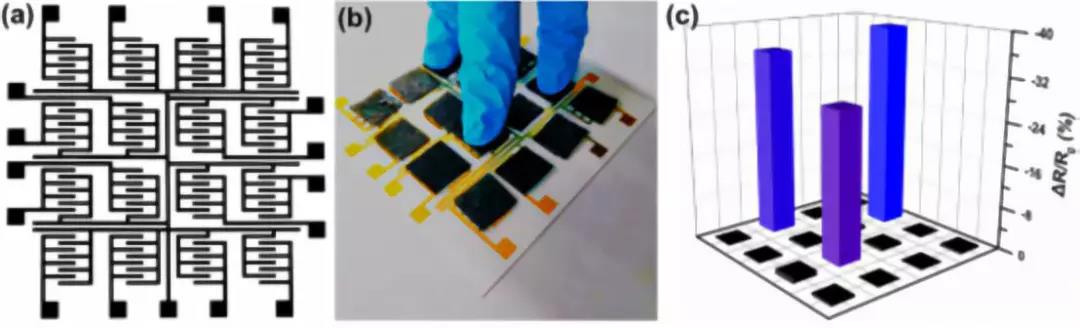

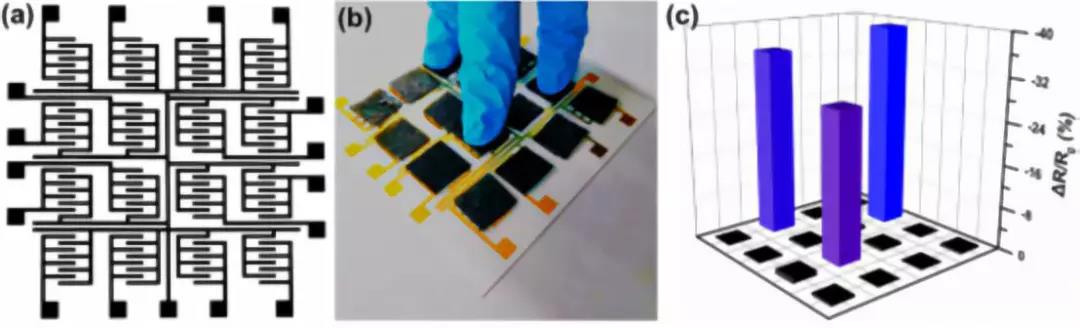

Figure 7. Fabrication of MPC electronic skin and pixel array.

[Summary of this article]

In this paper, a flexible piezoresistive pressure sensor was fabricated by depositing conductive MXene nanosheets on the framework of foamed Ni, then infiltrating PDMS, and then etching the foamed Ni substrate. Adjacent MXene sheets contact each other during deformation to form a dense conductive network. Therefore, the MPC flexible sensor has a wide working range of 0 ° -180 °, a relatively high ΔR / R0 of 90%, shows excellent consistency in 1000 cycles, and has high stability under a wide operating frequency. . Its ultra-low detection limit of 10 mg means its high sensitivity. The MPC flexible sensor can distinguish between different weights (10-600 mg) and the amplitude of oscillations caused by ultrasonic treatment of different solutions. It can also effectively monitor subtle movements (swallowing, facial muscle vibrations and stereo sound) and robust human movements (twisting fingers, bending and light / deep compression, elbow and neck movements), showing in the field of wearable smart devices huge potential.

Literature link:

https://doi.org/10.1016/j.jcis.2019.08.020.