(Nanowerk Spotlight) In view of the great interest and rapid development of graphene research, scientists now believe that the controlled preparation of graphene-based materials with layered structure and well-defined structure will achieve the high performance of graphene in various technologies Applications pave the way. Optoelectronics, energy storage, polymer composites and catalysis. Self-assembly technology has become the most effective strategy for this purpose.

(Nanowerk Spotlight) In view of the great interest and rapid development of graphene research, scientists now believe that the controlled preparation of graphene-based materials with layered structure and well-defined structure will achieve the high performance of graphene in various technologies Applications pave the way. Optoelectronics, energy storage, polymer composites and catalysis. Self-assembly technology has become the most effective strategy for this purpose.

Although two-dimensional (2D) self-assembly of graphene has been extensively studied from the perspective of basic research and commercial applications, two-dimensional (3D) nano-scale graphene self-assembly has been studied as a functional macrostructure with a clear network still exists. This is a huge challenge and an important obstacle to achieving practical applications. Now, Chinese researchers have demonstrated a step-by-step hydrothermal method to successfully prepare self-assembled graphene hydrogels, providing a solution to this problem.

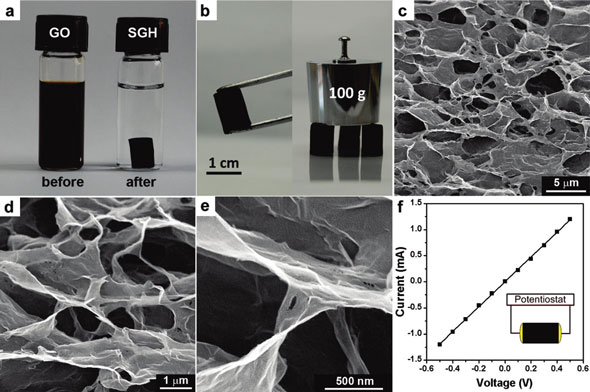

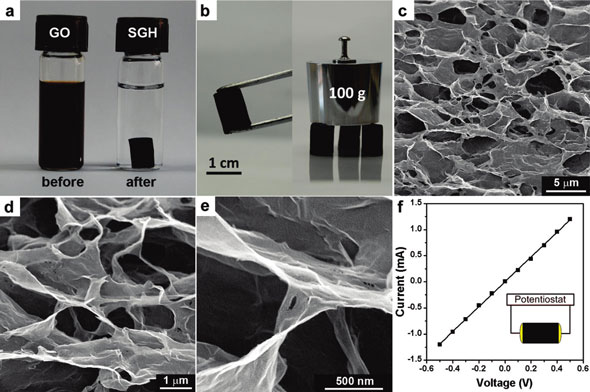

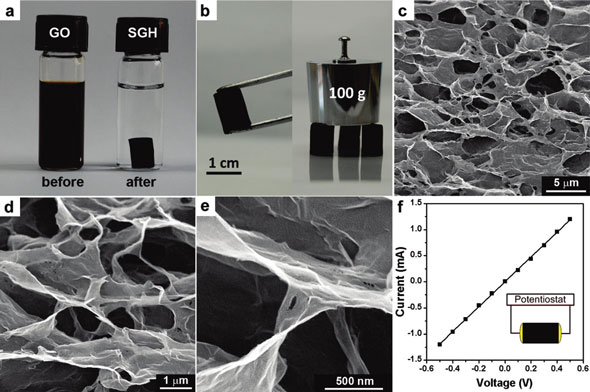

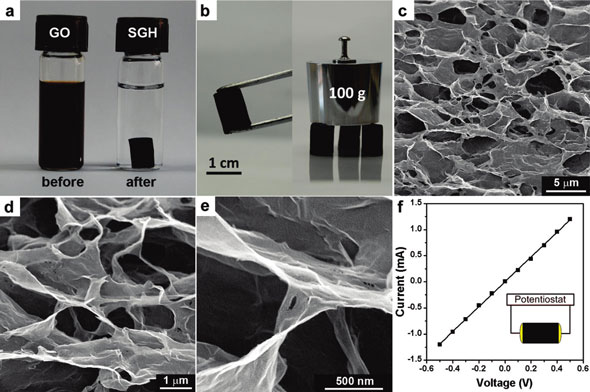

"We successfully prepared an aqueous dispersion of graphene oxide (a compound of carbon, oxygen, and hydrogen obtained by treating graphite with a strong oxidant) by hydrothermal reduction, and successfully prepared a high mechanical strength with high specific capacitance, good electrical conductivity and thermal stability Self-assembled graphene hydrogel. "Gao Quanquan, a professor in the Department of Chemistry at Tsinghua University in Beijing, told Nanowerk. "Our approach is simple, scalable and environmentally friendly."

In the online version of ACS Nano ("Self-Assembly Graphene Hydrogels by One-Step Hydrothermal Method") on June 30, 2010, Shi and his team reported a high-performance self-assembled graphene hydrogel- The first example of self-assembly made a 2D graphene sheet into a 3D macrostructure in a convenient one-step process.

Self-assembled hydrogels generally have low mechanical strength, thermal instability, and electrical insulation. Researchers at Tsinghua University have discovered that a simple one-step hydrothermal method can be used to reduce graphene oxide uniformly dispersed in water and self-assemble it into a high-performance graphene hydrogel.

The self-assembled graphene hydrogel contains approximately 2.6% (by weight) graphene flakes and 97.4% water, and has an electrical conductivity as high as 0.005 S / cm. In addition, it is thermally stable in the temperature range of 25-100 ° C, and its storage modulus (450-490kPa) is about 1-3 orders of magnitude higher than a conventional self-assembled hydrogel. This hydrogel used as a 3D supercapacitor electrode material shows a high specific capacitance (175 F / g) in an aqueous electrolyte.

(A) Photographs of a 2 mg / mL homogeneous graphene oxide aqueous dispersion before and after hydrothermal reduction at 180 ° C for 12 hours; (b) Photographs of a strong self-assembled graphene hydrogel, easy to handle and support weight (Ce) SEM images with different magnifications of the internal microstructure of the self-assembled graphene hydrogel; (f) Room temperature IV curve of the self-assembled graphene hydrogel showing ohmic characteristics, the illustration shows the conductivity measurement Dual probe method. (Reprinted with permission from the American Chemical Society)

Shi pointed out that previous research work has successfully proved that the self-assembly of graphene structural units is a functional thin film, which is an important graphene-based material, such as transparent conductive films and strong paper-like materials, among which graphene sheets Were assembled into one. The almost parallel way turns into a layered structure.

He said: "People naturally think that the 2D structural properties of graphene always lead to this 2D self-assembly behavior." "So, we set out to find out if there is an effective way to self-assemble 2D nano-scale graphene into a well-defined Functional macrostructure of the network. "

Based on their experiments, the researchers proposed a reasonable mechanism for forming self-assembled graphene hydrogels: before reduction, due to its strong hydrophilicity and electrostatic repulsion, graphite oxide sheets were randomly dispersed in water and expanding. status. When graphite sheets are hydrothermally reduced, they become regionally hydrophobic due to their restored conjugated domains and reduced oxidation functions. The combination of hydrophobic and π-π interactions results in 3D random packing between flexible graphene sheets.

"If the concentration of graphite oxide is high enough, cross-linking occurs in time through the partial overlap of the flexible graphene sheets, and eventually enough cross-linking sites are formed to form a 3D network with a pore size ranging from sub-microns to a few micrometers." Processing. "At the same time, the remaining oxidized functional groups on the graphene sheet will trap enough water in the graphene network at high temperature and pressure to form a graphene hydrogel. However, when the concentration of graphite oxide is low, the cross-linking will be very Difficult to carry out. Since the chance of contact between graphene sheets dispersed in an aqueous medium is low, it occurs in time.

SGH‘s excellent mechanical, electrical, and thermal properties, as well as the inherent biocompatibility of carbon materials, seem to make it attractive in a variety of applications, such as drug delivery, tissue scaffolds, high-performance nanocomposites, and supercapacitors.

In addition, the method developed by Shi‘s team is simple, environmentally friendly, and can be extended to the manufacture of various nanocomposites. This work is also noteworthy because it provides a deeper understanding of the self-assembly behavior of functionalized graphene as a 2D molecular building block. This discovery will inspire new layered and functional material designs based on graphene.

"About graphene is a universal and unique building block, there is a lot of space to discover new assembly behaviors of graphene itself or with other functional building blocks, such as macromolecules and inorganic nanoparticles. "Design and preparation materials for graphene functional groups," Shi said. "Given the research progress in this field, we can predict that self-assembled graphene-based functional materials with high performance and even stimulus response will appear in the near future."

Source: Nanowerk