hotline£º

17715390137

Tel/Wechat£º

18101240246 (Technology)

0512-68565571

Email£ºmxenes@163.com £¨Sales Engineer£©bkxc.bonnie@gmail.com

Scan the code to follow or search the official account on WeChat:

2D Materials Fronrier After paying attention,

click on the lower right corner to contact us,

Enter enterprise WeChat.

Professional Services Online

Recently, Zhang Chuanfang¡®s research team at the Federal Institute of Materials Science of the Swiss Federal Institute of Technology reported that the MXene waste precipitate was converted into an additive-free high-viscosity aqueous ink and used for large-scale screen printing to obtain batches of high-precision, high-performance Electronic devices and components, such as miniature solid supercapacitors, integrated circuits, wires, smart QR codes, etc. When used as a miniature supercapacitor, the device exhibits very high areal capacity and overall energy density.The work was published in the international top journal Advanced Materials .

[Frontier Advances]

The direct printing technology of functional materials provides the possibility of personalization and batch production of intelligent electronic components. Compared with traditional manufacturing processes, screen printing (also known as screen printing) technology allows users to digitally produce devices, reduce material losses, shorten production cycles, and realize batch intelligent manufacturing. The core technology of screen printing is to develop inks with high viscosity and solid content.In the currently reported work of printing microdevices, most functional inks contain additives. These additives can be used to regulate the rheological properties of the ink, improve the conductivity of printed lines, or add a two-phase solvent to change the dispersibility of the material. However, the subsequent processing of additives makes the printing process complicated, and some materials cannot withstand high temperature processing. Exploring a path that can improve the conductivity and mechanical properties of the electrode without adding additives or two-phase solvents, and without heat treatment, has important practical application value. In other words, the development of highly conductive, highly viscous inks without additives is essential for low-cost, large-scale screen-printed micro-energy storage devices and other microelectronic components.

As an emerging family of two-dimensional materials, transition metal carbonitrides (commonly known as MXene) have received unprecedented attention. Many studies have confirmed that MXene is a good energy storage material. Among them, Ti ₃ C ₂MXene has the advantages of ultra-high electrical conductivity (~ 15000 S / cm), excellent mechanical strength, and good energy storage characteristics. However,applying MXene to screen printing has many challenges . For one , screen printing requires a thick solid ink. The stripping yield of MXene nanosheets is low (~ 10-20%) and the concentration is low (~ 5 mg / mL), so it is difficult to prepare a large number of inks that meet the requirements of screen printing, resulting in low device preparation efficiency. Second , Choice of solvents. Two-dimensional materials are usually easier to disperse in organic solvents, and batch preparation will inevitably lead to thermal volatilization of a large number of environmentally unfriendly solvents, leading to increased subsequent processing costs. Third, the physical properties of the ink and the printing substrate match. Only when the surface chemistry of the substrate is appropriate can the ink wet the substrate well and adhere tightly to the substrate without falling off. Fourth, the volatility kinetics of the solvent. The drying dynamics of the droplets control the accuracy and resolution of the printed device.

In order to meet the above-mentioned challenges, the general countermeasures are to disperse MXene in organic solvents, or introduce additives / two-phase solvents, thereby improving the rheological properties of MXene inks and increasing the viscosity; or by concentrating the stripped MXene nanosheets to obtain high Thick MXene water-based ink. Although this can obtain a stable MXene paste and 3D print, however, the low stripping efficiency and subsequent concentration process greatly increase the device manufacturing cost .

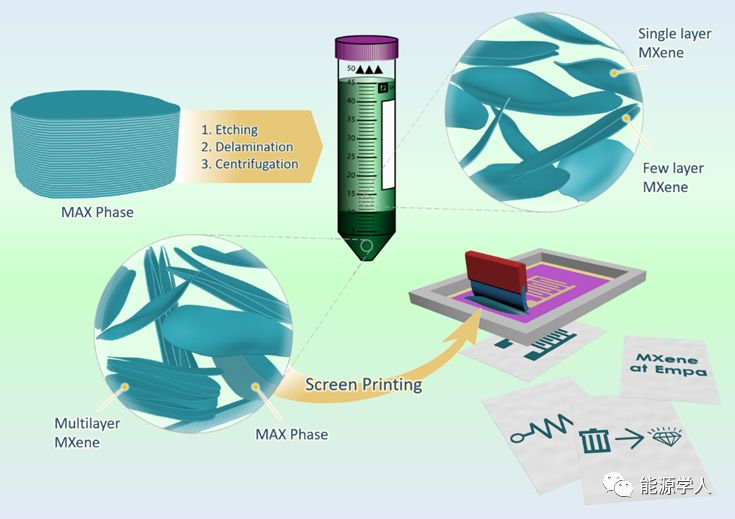

For this reason, the researchers in this article have taken a different approach and proceeded from the basic fact that MXene has a low stripping yield. They chose to use a large amount of waste precipitate (~ 80-90%) after MXene stripping as an active material, by adding a very small portion of MXene Peel off the nanosheets, and optimize the ink preparation process and rheological properties, so that the normally discarded MXene waste precipitate is turned into a treasure, and a highly conductive, highly conductive water-based ink is obtained. With the use of screen printing, high precision is achieved Large-scale printing and intelligent manufacturing of high-performance micro super capacitors and other microelectronic components, as shown in Figure 1.

Schematic: Turn waste into treasure-MXene waste sediment for screen printing microelectronic devices

Figure 1 Physical properties of waste ink based on MXene

Figure 2 Printed pattern and its characterization based on MXene waste sedimentary ink

The researchers found that the solids content of the ink modulation up to 25 to 34% at concentrations up to 150 mg / mL (FIG. 1), the printed lines exhibit high accuracy, and the printing pattern diversity, either two-dimensional code printed intelligence, and It can print electronic components such as wires, antennas, integrated circuits, micro super capacitors, etc., and has high line conductivity (up to 600 S / cm) and good mechanical toughness. The resistance is almost unchanged after repeated bending 15,000 times. The reason is that a very small amount of MXene nanolayers are added, which acts as a conductive binder, effectively bonding the multilayer MXene particles and the unreacted MAX conductive filler together to achieve an excellent Electronic and mechanical properties (Figure 2).

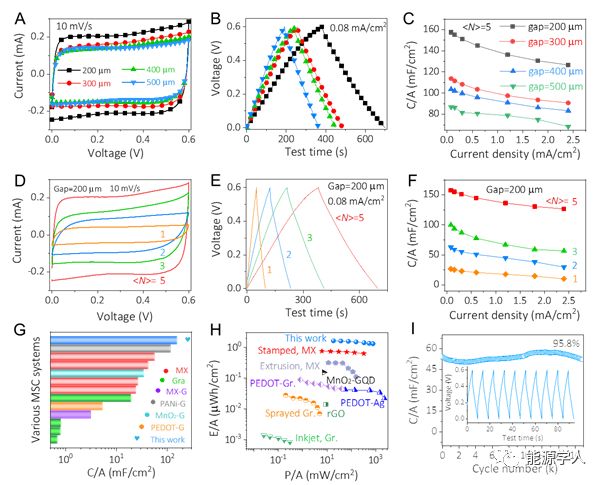

Figure 3 Performance evaluation of miniature capacitors

Figure 4 Performance optimization of screen printed microcapacitor devices

Researchers have found that micro-supercapacitors printed based on MXene waste sedimentary ink have very good energy storage characteristics of ØÍ capacitors, such as high surface capacity, 1,000 times of bending performance with almost no degradation (Figure 3), high energy density, 18,000 cycles The capacity retention rate is 95.8% (Figure 4).

Not only that, the researchers further demonstrated the large-scale and batch production of these high-performance microelectronic devices. As shown in Figure 5, by optimizing the design of the screen pattern, the additive-free aqueous ink based on MXene waste sedimentation can realize the preparation of thousands of devices in one minute. When used as a miniature capacitor, it has high capacity, high magnification, and Series and parallel meet energy and power requirements. Because the ink is formulated based on waste sediments, the cost is greatly reduced, thus showing a bright future in the topic of batch production of high-performance microelectronic devices.

Figure 5 Batch and large-scale printed microelectronic devices

In fact, the importance of direct printing MXene ink technology is self-evident, and its application is not limited to the field of energy conversion and storage, but in other fields such as electronic circuits, electromagnetic shielding, antennas, radio frequency identification, smart packaging, the Internet of Things and Sensors and other fields need integration, individualization, and scale, and the technology also has great potential application value.

[Summary and Prospect]

Based on MXene waste precipitation, the researchers in this paper developed a high solid content, additive-free, highly conductive water-based ink for efficient printing of micro-energy storage devices and electronic components. This idea of turning waste into treasure greatly reduces the production cost of devices, greatly broadens the application of MXene in the fields of electronics, circuits, and energy storage, and points out the direction for large-scale, integrated preparation of high-performance devices.

about the author:

In the past 3 years, Zhang Chuanfang (Senior Scientist) of the Federal Institute of Materials of the Swiss Federal Institute of Technology (Switzerland) has made continuous progress in the research of the preparation, energy storage, application, and manufacturing of MXene.By exploring the preparation process of MXene, MXene water-based, oil-based viscous inks, sedimentary inks, and composite inks were developed, the instability mechanism of MXene was clarified, and effective measures to significantly extend the life of MXene were proposed. It was widely adopted by many MXene research teams . The developed MXene ink exhibits excellent energy storage characteristics in the fields of super capacitors, transparent conductive films, high-capacity and high-capacity lithium-ion batteries, sodium-ion batteries, lithium metal batteries, and lithium sulfur batteries. These related research works have been published in Springer Nature (monograph), Nature Energy, Nature Communications, Adv. Mater., Adv. Funct. Mater., Adv. Sci., ACS Nano, Small, Nano Energy, Energy Storage Mater., Chem Mater., Adv. Opt. Mater., JMCA and other journals, cited more than 4,000 SCI papers, and applied for a series of invention patents in the fields of ink development and high surface capacity silicon anode, etc. Experimental Researcher of the Year, Young Leader of the Year, and Top 10 Leading Technologists of Chinese Chinese in Europe in 2019.

S. Abdolhosseinzadeh, R. Schneider, A. Verma, J. Heier, * F. N¨¹esch, and C. (John) Zhang *, Turning Trash into Treasure: Additive Free MXene Sediment Inks for Screen-Printed Micro-Supercapacitors, Advanced Materials , 2020, 2000716, DOI: 10.1002 / adma.202000716

| Reminder: Beijing Beike New Material Technology Co., Ltd. supplies products only for scientific research, not for humans |

| All rights reserved © 2019 beijing beike new material Technology Co., Ltd ¾©ICP±¸16054715-2ºÅ |