[ Introduction ]

"Self-assembly" spontaneously organizes the structural units of molecules or colloidal particles into larger or ordered structures through non-covalent interactions, such as hydrophobic interactions, hydrogen bonding, and electrostatic interactions. A typical example is the self-assembly of amphiphilic molecules such as lipids, surfactants or amphiphilic block copolymers (BCP). These amphiphilic molecules contain both hydrophobic and hydrophilic groups and can be assembled into a variety of functional nanostructures in selective solvents, such as micelles with different shapes, hollow tubules, and vesicles.

Over the past two decades, the controlled synthesis of inorganic nanoparticles (NPs) has provided assembled building blocks that can be used to build functional materials. Many of the NPs exhibit compelling optical, electronic, and magnetic properties that depend to a large extent on their size, shape, and composition, as well as the mechanism of the NP‘s aggregate state. To exploit the great potential of NPs in energy conversion and storage, catalysis, sensing, nanomedicine, and optical and electronic devices, it is often necessary to assemble NPs into large or ordered structures with a macroscopic view. Typical strategies for assembling NPs include self-assembly using external fields at the interface, templated assembly using soft or hard templates, and self-assembly using solutions of molecular ligands. Organizing NPs into an ordered macrostructure not only links discrete NPs with macroscopic materials, but also produces colligative properties that may differ from individual NPs and their overall congeners. For example, noble metals (such as Au and Ag) NP are used for surface plasmon resonance (LSPR), which is the resonance of coherent oscillations of free electrons on the surface of NPs with incident light. In this ordered array of metal NPs, near-field plasmon resonance coupling between adjacent NPs allows electron resonance to propagate along the array, making it useful as an optical waveguide for light below the diffraction limit.

[ Achievement Profile ]

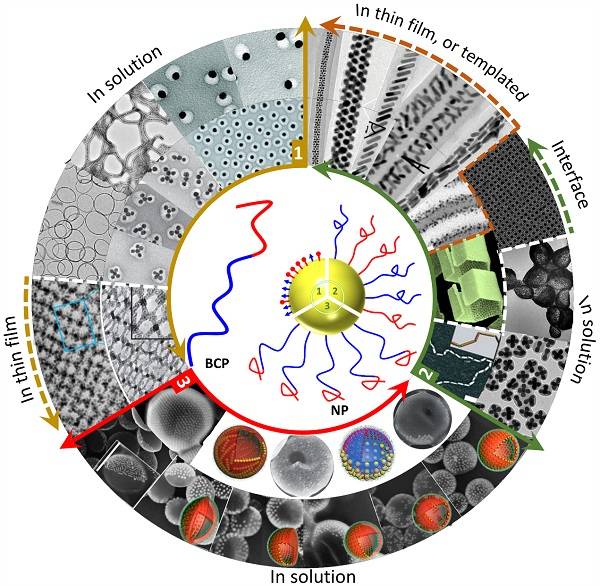

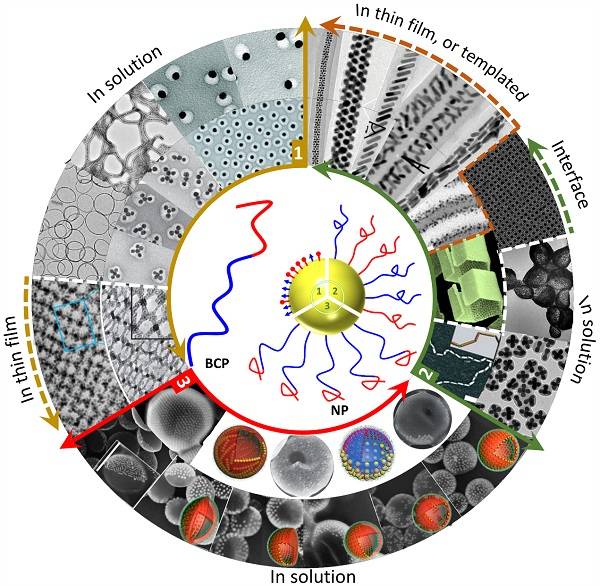

Professor Nie Zhihong of Fudan University and Professor He Jie of the University of Connecticut summarized the latest progress in polymer nano-assembly of polymer / inorganic hybrid materials under the guidance of polymers, focusing on the structural design of materials. The discussion of NP assembly will focus on (1) polymer matrices and small molecule ligand-stabilized inorganic NPs (SLNPs), (2) interactions between polymer matrices and polymer-grafted inorganic NPs (PGNP), ( 3) Structural control of the interaction between PGNP and polymer, including those composed of structures composed of random mixing of polymer and NP, functionalization of NP polymer, and structure assisted by polymer ligands of inorganic NP . The second part focuses on the correlation between the structure and properties of the building blocks, especially polymer-grafted NPs. In the third part, the author discusses the latest achievements in this field, including the self-assembly of polymers / NPs in the solid state (thin films), co-assembly of polymers and NPs, polymers as templates to induce the assembly of inorganic NPs, and polymers Self-assembly of Grafted NPs. In the fourth part, the author briefly introduces several representative applications of different types of nanocomposites. The achievements under the title " Polymer-Guided Assembly of Inorganic nanoparticles " published in Chem. Soc. Rev. on .

[Picture and text guide]

Scheme 1. Typical composite structure obtained by polymer-guided assembly of inorganic nanoparticles

Figure 1. Schematic diagrams of four typical chain conformations of nanoparticles grafted polymers

Figure 2. Chain conformation and phase separation behavior of mixed homopolymers uniformly grafted on the surface of spherical nanoparticles

(A) Spherical nanoparticles grafted with three different homopolymers with different 2 R 0 / d values (2 R 0 / d , which is the ratio of the mean square terminal distance of the homopolymer to the inner core radius of the nano particles)

(A) Spherical nanoparticles grafted with three different homopolymers with different 2 R 0 / d values (2 R 0 / d , which is the ratio of the mean square terminal distance of the homopolymer to the inner core radius of the nano particles)

(B) Molecular weight separation of poly-tert-butyl polyacrylate (P t BA, bright band phase region) and polystyrene (PS, dark band phase region ) uniformly grafted on the surface of 172 nm SiO 2 NPs. Impact

Figure 3. Phase behavior of grafted polystyrene on the surface of gold nanoparticles

(A) Schematic diagram of micellization of AuNP surface grafted polystyrene in a selective solvent

(B, c) Effect of AuNP size and polymer size on micellization of PS

(D) Effects of different morphologies of inorganic nanoparticles on the surface grafted PS micelles

(E) Phase diagram of the effect of grafting density and NP size on the patterning of grafted polymers on the surface of gold nanoparticles

Figure 4. Patterning of amphiphilic AB block copolymer BCPs on the surface of NP

(A) Simulation results of surface patterned structures of several representative single nanoparticles

(B) Phase diagram of the effect of BCP grafting density and volume fraction of solvent-resolving segment f B on the surface patterning of nanoparticles

Figure 5. Effect of nanoparticle size on the distribution of SLNPs in polymer films

(A) Preparation method of typical supramolecular / inorganic nanoparticle composite film material

(B) The spatial arrangement of 7.4 nm AuNPs and 5.5 nm PbS NPs in supramolecular PS 19k - b -P4VP 5.6k (PDP) 1.7 assembly film materials has obvious size dependence.

(C) Effect of NP size distribution on the final morphology of the obtained composite material

Figure 6. Effect of nanoparticle volume fraction ( f NP ) on co-assembly of SLNPs and BCP

(A) Spatial distribution of dodecanethiol-modified 4.9 nm AuNPs in supramolecular PS 19k - b -P4VP 5.2k (PDP) 1.7 assembly composite film when f NP increases from 0.4 vol% to 45 vol%

(B) A nano-composite membrane co-assembled from PI- b- PDMAEMA‘s BCP and Pt NPs with high f NP . After pyrolysis and calcination, a mesoporous platinum membrane with good catalytic properties was prepared.

(C) Bottle brush block copolymer BBCP and gallic acid-modified ZrO 2 NPs co-assemble to form a periodic layered photonic crystal (PhC) with a large refractive index difference through hydrogen bonding.

Figure 7. Restricted orientation and assembly of Au NRs selective electrostatic adsorption on the surface of block copolymer PS- b- P2VP film

Figure 8. Surface grafted polymer controls the self-orientation and assembly behavior of nanocubes in the matrix polymer

(A) Grafted polymers of different lengths control Ag NCs to self-assemble in an edge-to-edge or face-to-face mode

(B) AgNCs grafted with PVP form a chain-like structure in PS film in an edge-to-edge mode.

(C) PEO-grafted AgNCs form face-to-face orientation in the PS film to form a chain structure

Figure 9. Assembly phase diagram of H-PGNPs in the matrix polymer

Figure 10. Self-assembly of H-PGNPs guided by BCP phase separation structure as soft template

(A) AuNPs of grafted PS are assembled in the PS columnar phase of supramolecular PS- b- P4VP (PDP) matrix

(B) Assembly of mixed PS-grafted AuNRs in the supramolecular PS columnar phase

(C) Supramolecular P4VP (PDP) 1.0 induces PS-grafted Au NRs to assemble to form a superlattice structure

(D) PS-grafted Ag NPs are restricted to form a helical structure in the PS cylindrical phase of the PS- b- P4VP matrix.

Figure 11. PGNP self-assembled into a nanocomposite film

(A) Solvent evaporation induces the assembly of DNA-modified Au NPs to form superlattice films

(B) Self-assembly of Ag NCs grafted PS at the air / water interface

(C) NaZn 13 superlattice assembled from PS grafted 3.8 nm AuNPs and 14.3 nm Fe 3 O 4 NPs binary system at the diethylene glycol / air interface

(D) Incompatible PI and PS phase separation grafted on the surface of 2.8 nm Au NPs induces the arrangement of nanoparticles in the layered structure assembled

Figure 12 is . "Giant" self-assembled amphiphilic macromolecule film

(Ad) Chemical structure and molecular conformation models of four "giant" amphiphiles

(E) Ternary phase diagram of the phase structure of different "giant" amphiphilic films

(F) Chemical structure and molecular conformation models of four "ball-rod" type "giant" molecules

(G) Schematic diagram of the assembled thin film phase structure of 24 "ball-rod" type "giant" molecules in four series

Figure 13. Restricted self-assembly of PGNP

(A) Restricted self-assembly of Au NPs grafted PS in cylindrical anodized aluminum (AAO) nanopores

(B) Restricted assembly of Au NRs grafted PS in cylindrical nanopores of AAO under the control of an external electric field

(C) Thermal anneal distribution of PS-grafted AuNPs in PS matrix film under the limitation of trench pattern

(D) 3D restricted co-assembly of PGNPs and BCPs during volatilization of emulsion droplets

(E) 3D restricted co-assembly of different sizes of Au NPs grafted with different PS grafts

Figure 14. The role of amphiphilic BCPs in their solution co-assembly with SLNPs

(A) Spherical micelles of BCPs coated SLNPs with different hydrophilic and hydrophobic surfaces to prepare anisotropic nanoparticles

(B) BCPs micelles form specific shape and deformable masks on the surface of different shapes of NPs

(C) Assembly of BCPs micelle-wrapped SLNPs, which is beneficial for later stabilization, separation, purification and application

Figure 15. Effect of NP co-assembly with BCP in a selective solvent

(A) In a selective solvent DMF / H 2 O, PAA 41 - b -PS 193 and hydrophobic TOPO stabilized 4.6 nm QD are assembled into large composite micelles (LCMs) with layered nanostructures.

(B) Effect of solvents on co-assembly of PAA 38 - b -PS 247 and oleic acid-stabilized IONPs: 1-3, DMF / H 2 O; 4-6, THF / H 2 O

(C) Morphological transformation of PAA 38 - b -PS 73 and MNPs in selective solvents caused by increasing the volume fraction of MNP ( d = 5.6 nm)

Figure 16. Structural changes of composite micelles composed of BCPs and inorganic NPs

(A) Extraction of BCPs in the shell of carbon nanotubes to drive the carbon tubes to curl into a loop

(B) AuNPs wrapped by PS- b- PAA spherical micelles are assembled to form cylindrical micelles embedded with NP chains

Figure . 17 . Unimolecular micelles as a nano-reactor for in situ synthesis of spherical nanocrystals, the nanocrystals and the rod-shaped Nanodiscs

Figure 18. Self-assembly of CTAB- stabilized Au NRs grafted with PS at both ends in a selective solvent

Figure 19. H-PGNP with PAA- B -PS in solution co-assembled

(A) Au NPs grafted with PS are assembled under PAA- b -PS micelles to form highly symmetrical nanoclusters

(B) PSA grafted gold nano dumbbells are coated with PAA- b- PS micelles to form a cross assembly

Figure 20. Solution self-assembly of M-PGNP with an inert inorganic core

(A) "V-shaped" amphiphilic BCPs PS 40 - b -PEO 50 grafted 3 nm AuNPs form columnar micelles in a selective solvent, with AuNPs at the core / shell interface

(B) CdS NPs of grafted mixed homopolymer PS and PMAA self-assemble into vesicles, micelles, and columnar structures in a selective solvent

(C) Self-assembly of single molecule modified Au NPs (M-PGNP) into balls, rods and vesicles

Figure 21. M-PGNPs self-assemble to form vesicles

(A) 14 nm AuNPs grafted with hydrophilic PEO and hydrophobic PMMA were assembled by membrane hydration method to obtain vesicles

(B) Controlling the orientation of Janus nanoparticles in self-assembled vesicle membranes by modifying the hydrophilic and hydrophobic mixed segments on the surface of Janus Au-Fe 3 O 4nanoparticles, respectively.

Figure 22. Influence of structural parameters of B-PGNPs on their assembly behavior

(A) Schematic diagram of the configuration of terminal mercapto PEO- b -PS-SH grafted Au NP (B-PGNP)

(B) B-PGNP self-assembles to form vesicles by thin film hydration, and AuNPs form a single-layered hexagonal close-packed lattice structure in the vesicle membrane.

(C) Effect of Au NP core size d Au and PS block length on self-assembly of B-PGNPs in selective solvent THF / H 2 O

(D) Effect of graft density on self-assembly of B-PGNPs in selective solvent THF / H 2 O

Figure 23. Co-assembly of B-PGNPs with BCP and / or iron oxide NP

(A) HS-PS- b- PEO grafted Au NPs and free PS- b- PEO co-assemble to form hybrid vesicles with different morphologies and surface patterns

(B) HS-PS- b- PEO grafted Au NPs and free PS- b- PAA and MNPs co-assemble to form Janus vesicles with different morphologies of various inorganic components.

Figure 24. Self-assembled nanocomposite vesicles for tumor imaging and treatment

(A) Chain-like and non-chain-like vesicles formed by the assembly of PS- b- PEO grafted AuNPs as contrast agents for photoacoustic imaging of tumors in vivo

(B) Anticancer effect of doxorubicin (DOX) -loaded bilayer magnetic-plasma resonance vesicles

(C) Magnetic vesicles with a controllable MNP layer co-assembled by PS- b- PEO-grafted MNPs and PS- b- PAA for magnetically assisted targeted anti-tumor drug doxorubicin in tumors in vivo (DOX) Delivery

Figure 25. pH- responsive ultra-small iron oxide nanoparticles ESIONs assembly for mouse experiments (a) Schematic diagram of pH-sensitive magnetic nano-grenades (PMNs)

(a) Schematic diagram of pH-sensitive magnetic nano-grenades (PMNs)

(B) Schematic diagram of tumor treatment strategies recognizable using the pH of PMNs

(C) In vivo T1-weighted MR images and color images of tumor locations 2 h after intravenous injection of PMNs into nude mice bearing HCT116 tumors

(D) Heterogeneous tumor volume in the four treatment groups after treatment

Figure 26. Representative applications of functional nanocomposite films

(A) Single-layer superlattice composite film of AuNPs for storage devices

(B) PGNP-based composite materials as dielectric materials

(C) Combining diamond and SERS codes to generate a double-encoded verification code to use gold diamond dodecahedron (RD) plasma nanosheets as a security label for banknotes

(D) For gas separation membranes

【to sum up】

In this article, the author reviews the self-assembly of polymer-induced inorganic nanoparticles in films and solutions to form functional composites from an experimental perspective. The basic understanding of the correlation between thermodynamic / kinetic parameters and the assembly structure of polymer / NP nanocomposites is emphasized, which will help to establish predictions for using polymer-induced inorganic NP assembly strategies for material design and manufacturing frame. It will also accelerate the development of related fields from the following aspects: (i) promote the discovery of novel or advanced applications of the obtained materials in optoelectronics and nanomedicine; (ii) explore the assembly and composition of inorganic nanoparticles with multilayered structures Structure-performance relationship of materials. Although great progress has been made in this area, there are still some challenges that require our continued research in this area.

Literature link : Polymer-guided assembly of inorganic nanoparticles . Chem. Soc. Rev., 2019, DOI: 10.1039 / c9cs00725c