¡¾Research Background¡¿

With the coming of the rapid development of flexible and wearable microelectronic technology, the Internet of Things and self-powered microsystems urgently need to explore new types of advanced microelectrochemical energy storage devices with high performance that are different from the current stacked microbattery technology. In order to achieve this goal, among many key strategies, a planar micro power supply without a diaphragm, as a highly competitive power supply system, has recently attracted widespread attention. Compatibility of traits and performance allows for seamless integration of complex-shaped electronic systems. Planar sodium ion microbatteries (NIMBs) are considered as a new type of potential micropower, but still need to face many challenges.

[Achievement Profile]

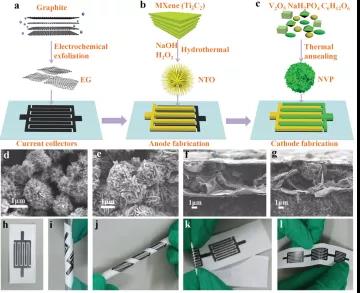

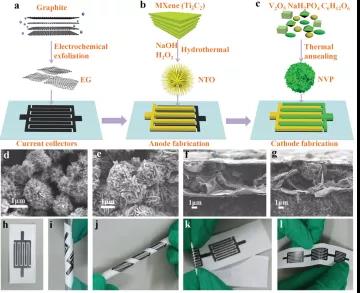

Recently, Professor Wu Zhongshuai of Dalian Institute of Chemical Technology and Professor Yu Yan of the Chinese University of Science and Technology published a research paper entitled: Ionogel-based sodiumion micro-batteries with a 3D Na-ion diffusion mechanism enable ultrahigh rate capability in the international top academic journal Energy & Environmental Science . In this study , a flexible non-aqueous planar NIMBs based on sodium titanate as a negative electrode and a sodium vanadium phosphate positive electrode was prepared. The positive and negative electrode materials were embedded in a 3D conductive graphene network using NaBF 4 -based ionic gel electrolyte. It has a very high ionic conductivity: 8.1 mS cm -1 . The prepared NIMBs show considerable area energy density, stable rate performance, outstanding flexibility, and controllable voltage and capacity output, which can all be attributed to the excellent coupling effect of planar geometry, and multi-directional sodium ions Contribution of diffusion channel and chirp capacitor. In addition, researchers have proposed an ideal in situ characterization model for exploring the energy storage mechanism of microscale planar energy storage devices.

[Picture and text guide]

Figure 1. Schematic diagram of the preparation process of NIMBs, micromorphological characterization of electrode materials, and display of macroscopic devices.

Figure 2. Electrochemical performance of ionic gel electrolytes NIMBs.

Figure 3. Study of sodium ion storage mechanism.

Figure 4. Schematic of 3D multi-directional sodium ion diffusion.

Figure 5. Flexibility and high temperature performance tests of NIMBs.

[Summary of this article]

In summary, a quasi-solid-state planar ionic gel-based NIMBs, a sea urchin-like NTO negative electrode and a flower-like NVP positive electrode are designed and prepared in this paper. EG is used as a 2D additive. It is a soft metal-free current collector with Stable structure, high conductivity and outstanding flexibility. By combining the contribution of high ion-conducting NaBF4-based ionic gel electrolyte and samarium capacitor, the assembled NTO / NaBF4-IE / NVP has a high volume capacity, enhanced rate performance, high-temperature stability to 100 ¡ã C, and ultra-high stability. High area energy density of 145 ¦ÌW h cm -2 (55.6 mWh cm -3 ). In addition, a 3D multi-directional sodium ion diffusion path can improve the performance of a planar microbattery. This research establishes an in situ characterization model for studying the energy storage mechanism for NIMBs and other microbatteries, which has great potential in the potential applications of other microelectronics or microsystems.

Literature link:

DOI: 10.1039 / c9ee03219c

Source: MXene Frontier