已传文件:photo/20207259253375.png

introduction

Cellulose is a widely distributed and abundant natural polymer material in nature. As an important material in the pulp and paper industry, its application fields are not only used for the production of paper and functional paper, but also for the development of nano cellulose and its deep applications. . In recent years, as a renewable and environmentally friendly nanomaterial, nanocellulose derived from cellulose has attracted the attention of many researchers. It not only possesses the basic characteristics of cellulose, but also has typical characteristics of nanomaterials, such as quality. Light, high surface activity, large specific surface area, high Young‘s modulus, strong adsorption capacity and high reactivity, etc., endow nano cellulose with unique optical properties, rheological properties and mechanical properties. It has broad applications in pulping and papermaking. Its application prospects, such as the reinforcement of pulp, the retention of fine fibers and fillers, etc., can also be applied to fields such as nanomedicine, packaging materials, food industry and building materials. At present, flexible and compressible porous lightweight materials have the advantages of adjustable three-dimensional hierarchical structure, high porosity and pore volume, high specific surface area, etc. The development of flexible energy storage devices as a new bulk electrode material has important research significance and innovation Sexual development. Compared with conventional self-assembly methods (such as hydrothermal, hard/soft templates), the porous carbon structure is poorly controllable or the material mechanical properties cannot meet the requirements of flexibility and compression, the preparation process is cumbersome, and the preparation conditions are harsh. , Nanocellulose prepared from wood has the characteristics of large aspect ratio, high mechanical strength, and easy self-assembly. We use the flexibility and high aspect ratio of nanocellulose combined with a freeze-casting-oriented growth strategy to give play to the physical structure of nanocellulose Performance control advantages are used in the design of advanced flexible energy storage materials.

Introduction

At present, the team of Professor Xinwen Peng from South China University of Technology has demonstrated a simple manufacturing strategy for nanocellulose-oriented preparation of iron-based carbon aerogels, using nanocellulose to help prepare bulk self-supporting flexible air electrode materials, through directional freezing casting-annealing Process and synthesize a 3D honeycomb nanostructure with Fe-containing compound grown in situ. The application of this electrode material to self-supporting flexible zinc-air batteries and flowing zinc-air batteries shows excellent ORR/OER electrocatalytic activity, cycle stability and high energy efficiency. The result was recently published in Adv. Mater. 2020, 2002292 as "An Iron-Decorated Carbon Aerogel for Rechargeable Flow and Flexible Zn-Air Batteries".

Graphic guide

Figure 1 Synthesis schematic and structure characterization of FeP/Fe2O3@NPCA carbon aerogel

(A) FeP/Fe2O3 supported N, P-doped porous carbon aerogels.

(B) Compression of carbon aerogel.

(C-f) Aerogel before carbonization c) Digital photograph and d) Side view SEM image. Carbonized carbon aerogel e) digital photo and f) top-view SEM image.

Figure 2 Phase and structure characterization of FeP/Fe2O3@NPCA carbon aerogel.

(A) TEM images of different resolutions.

(B) The HR-TEM image shows the presence of FeP and Fe2O3 nanoparticles.

(C) XRD pattern.

(D) HAADF-STEM image and corresponding element distribution map.

(E-g) e) Fe L-edge, f) C K-edge and g) N K-edge XANES spectra.

(H-j) XPS spectrum of carbon aerogel.

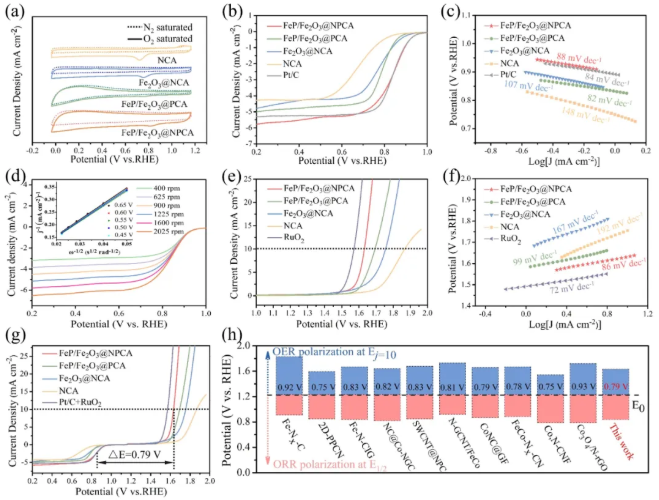

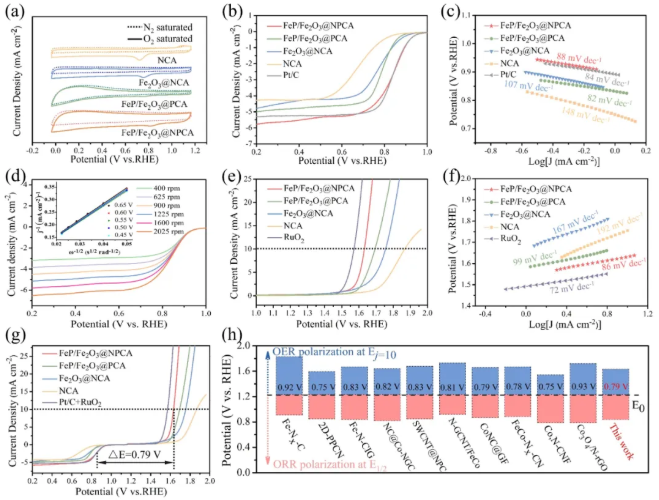

Figure 3 Electrochemical performance of FeP/Fe2O3@NPCA carbon aerogel

(A) CV curve under N2 or O2 saturated 0.1 M KOH solution.

(B) RDE polarization curve of ORR at 1,600 rpm.

(C) Tafel curve obtained from polarization curve.

(D) LSV curve at different speeds.

(E) RDE polarization curve of iR compensation OER.

(F) Tafel curve obtained from polarization curve.

(G) Polarization curves of a series of carbon aerogel catalysts and Pt/C+RuO2 bifunctional catalytic activity.

(H) Comparison of △E between FeP/Fe2O3@NPCA catalyst and literature catalyst.

Figure 4 FeP/Fe2O3@NPCA water-based zinc-air battery performance

(A) Schematic diagram of rechargeable zinc-air battery based on FeP/Fe2O3@NPCA air cathode water system.

(B) Constant current discharge curve under different current density.

(C) Charge and discharge electric polarization curve and corresponding power density curve.

(D) Constant current discharge test under different current densities, the specific capacity is standardized by the quality of zinc anode.

(E) Charge and discharge curves of FeP/Fe2O3@NPCA and Pt/C+RuO2 ZAB at a current density of 5 mA cm-2.

(F) Cycle charge-discharge curve of FeP/Fe2O3@NPCA-based ZAB at current density of 1, 5, 10 mA cm-2.

(G) Schematic diagram based on FeP/Fe2O3@NPCA flow-type zinc-air battery. h) Charge and discharge curve of powdered FeP/Fe2O3@NPCA-based mobile ZAB at a current density of 5, 20 mA cm-2. i) Charging and discharging curve of bulk FeP/Fe2O3@NPCA-based mobile ZAB at a current density of 5 mA cm-2.

Figure 5 FeP/Fe2O3@NPCA solid-state zinc-air battery performance

(A) Schematic diagram of solid-state ZAB assembled with FeP/Fe2O3@NPCA self-supporting air electrode.

(B) Charge and discharge polarization curve and power density curve of FeP/Fe2O3@NPCA-based solid-state ZAB.

(C) Constant current discharge curve at a current density of 5mA cm-2.

(D) Cycle charge-discharge curve at current density of 5 mA cm-2.

(E) Charge and discharge curves at different bending angles and current density of 5 mA cm-2.

(F) Three solid-state ZABs are connected in series to supply power to 12 LEDs in a straight/bent state.

summary

This study reports a simple strategy for preparing iron-based N, P-doped carbon aerogels based on 3D interconnected structures assembled from wood-derived nanocellulose. The FeP with in-situ growth is synthesized by directional freeze casting-annealing treatment. /Fe2O3 nanoparticles 3D honeycomb nanostructure. The prepared carbon aerogel has good mechanical stability and flexible porous structure, which can realize effective gas/electrolyte diffusion and good conductivity. Thanks to the synergy between iron oxide/phosphide and nitrogen and phosphorus-doped carbon nanosheets, FeP/Fe2O3@NPCA carbon aerogel exhibits significant ORR/OER electrocatalytic activity. Based on the above advantages, the iron-based modified carbon aerogel can be used as a "breathable" and "compressible" high-performance wood-derived air electrode, which can be used as an excellent cathode material in conventional water-based ZAB, or a medium-dimensional type of flowing ZAB and flexible solid ZAB Self-supporting air cathode with high capacity, long-lasting cycle charging stability and high energy efficiency. This work is a major progress in the high-value utilization of biomass and the functionalization of cellulose-derived materials. It is believed that free-standing carbon aerogel-derived electrodes also have broad application prospects in many other related fields of energy conversion and storage. The first author of this article is Wu Kunze, a postgraduate student of South China University of Technology, Zhang Lei and Yuan Yifei are the co-first authors, and the corresponding authors are Professor Xinwen Peng of South China University of Technology and Researcher Lu Jun of Argonne National Laboratory.

This information is sourced from the Internet for academic exchange only. If there is any infringement, please contact us to delete it immediately.