已传文件:photo/202073191332581.png

In recent years, with the rapid development of electric vehicles and mobile electronic devices, the performance of lithium-ion batteries has become an important factor affecting their applications. How to improve the energy density and fast charge-discharge performance of lithium-ion batteries has gradually become a research focus in the field of lithium-ion batteries. Traditional graphite electrodes cannot meet the development requirements of high-performance lithium-ion batteries due to limitations in energy density and charge-discharge rate. Compared with traditional graphite electrodes, emerging anode materials such as silicon, germanium and tin with higher specific capacity are expected to become important anode materials for next-generation lithium-ion batteries.

The silicon anode has a very high specific capacity and has become the primary choice for the next generation of lithium-ion battery anode materials. However, its low conductivity and large volume change have become important factors hindering its application. Compared with silicon, metal germanium has a higher specific capacity (1600 mAh/g, Li4.4Ge), good conductivity and excellent fast charge and discharge performance. However, its volume change of up to 300% during the charging and discharging process will lead to poor cycle performance and affect its practical application as a negative electrode material. The Junjie Niu research group of the University of Wisconsin-Milwaukee (UW-Milwaukee) is mainly engaged in the research and development of new lithium-ion batteries. In order to improve the stability of the negative electrode material during the rapid charge and discharge process, increase the lithium ion transmission rate, and improve the conductivity, the researchers of the research group chose the new two-dimensional material MXene as the supporting material, the metal oxide GeOx as the active material, and the wet The chemical method successfully prepared a new type of negative electrode material. The special layered structure of the supporting material MXene can provide sufficient space capacity for the volume change of the active material during the charge and discharge process to maintain the stability of the structure. The excellent conductivity of MXene is conducive to the improvement of the charge and discharge rate of electrode materials. At the same time, the presence of functional groups on the surface of MXene facilitates the uniform adhesion and film formation of amorphous GeOx during the preparation process (Figure 1).

Figure 1. Material preparation process and TEM characterization.

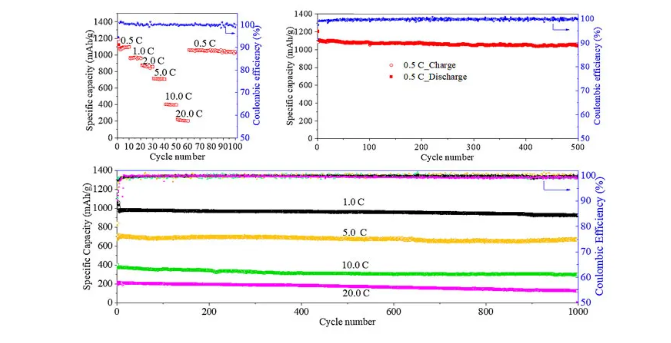

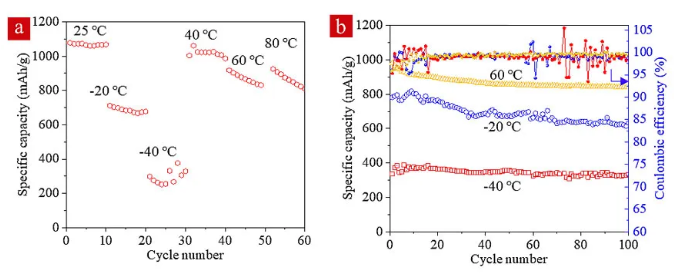

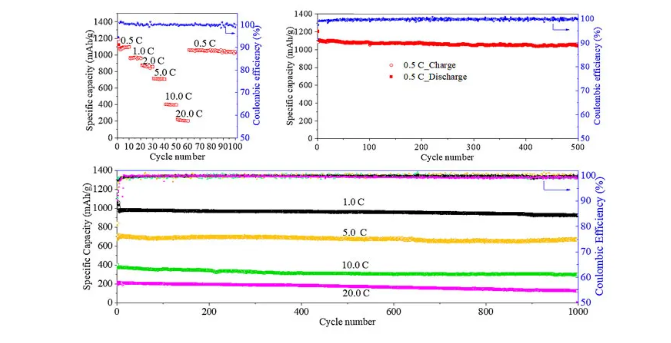

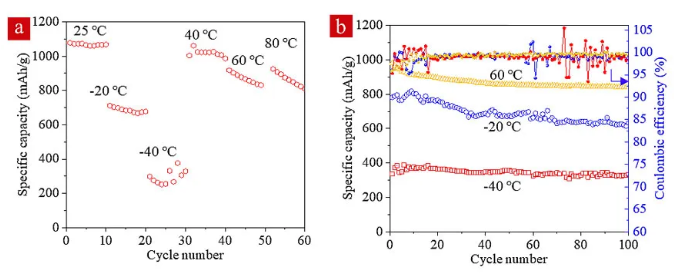

The final generated new anode material with a special three-dimensional structure can maintain a specific capacity of 1048.1 mAh/g after 500 cycles at a 0.5C rate. The specific capacity remains at 929.6 mAh/g after 1000 cycles at 1.0 rate, and the capacity loss is less than 0.02%/cycle. At the same time, charging and discharging at a rate of up to 20C can be achieved (Figure 2). In the temperature range of -40 to 60 ℃, it shows a higher specific capacity and stable cycle performance (Figure 3). The new negative electrode material is expected to be used in electric vehicles, mobile electronic equipment and electronic equipment used in extreme temperature environments.

Figure 2. Cycle performance at 0.5C to 20C as a negative electrode material for lithium-ion batteries.

Figure 3. Cycle performance from -40°C to 80°C.

This result was recently published on ACS Nano. The first author of the article is UW-Milwaukee PhD student Mingwei Shang, and the corresponding author is Junjie Niu.

This information is sourced from the Internet for academic exchange only. If there is any infringement, please contact us to delete it immediately.