Introduction

This study aims to explore the effect of salt on the properties of CNF (Nanocellulose) suspensions. We evaluated the flocculation performance of CNF suspension in the presence of two different salts: sodium chloride (NaCl) and calcium chloride (CaCl2). The precipitation behavior was used to characterize the aggregate properties of nanofibers aggregated in the presence of salt, and the effect of salt on the network strength and dehydration capacity of CNF suspension was evaluated.

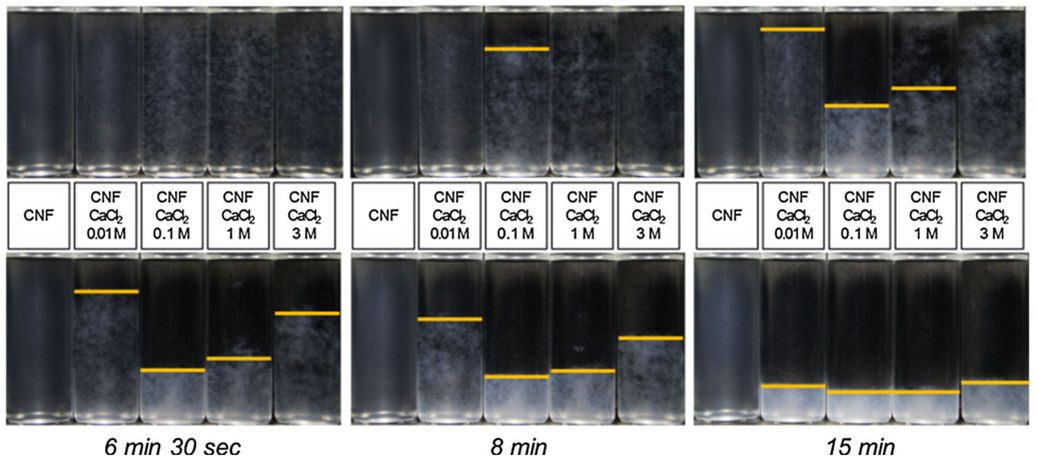

In this paper, static multiple light scattering (Turbiscan) and multi-speckle diffusion spectroscopy (Rheolaser) techniques are used to jointly study the network structure strength of nanocellulose under different salt conditions.

Results and discussion

1. The influence of salt on suspension performance

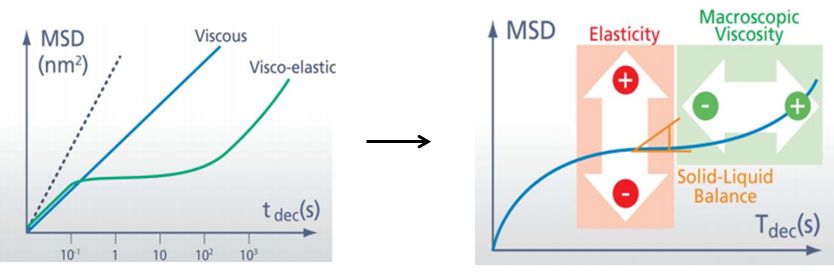

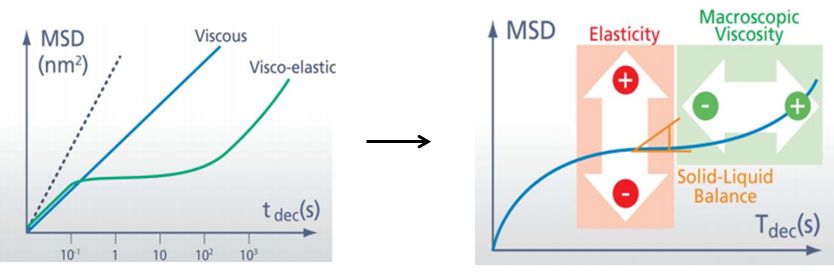

CNF suspension+NaCl

The above figure shows the photos of CNF suspension with NaCl added at different moments. The layered interface of the agglomerates is marked with a yellow line. It can be seen from the figure that the precipitation speed of CNF suspension increases with the increase of NaCl concentration. In the photo at 25 min, it can be seen that in the presence of NaCl, the height of the precipitation layer is close, indicating that NaCl affects the network structure of nanocellulose.

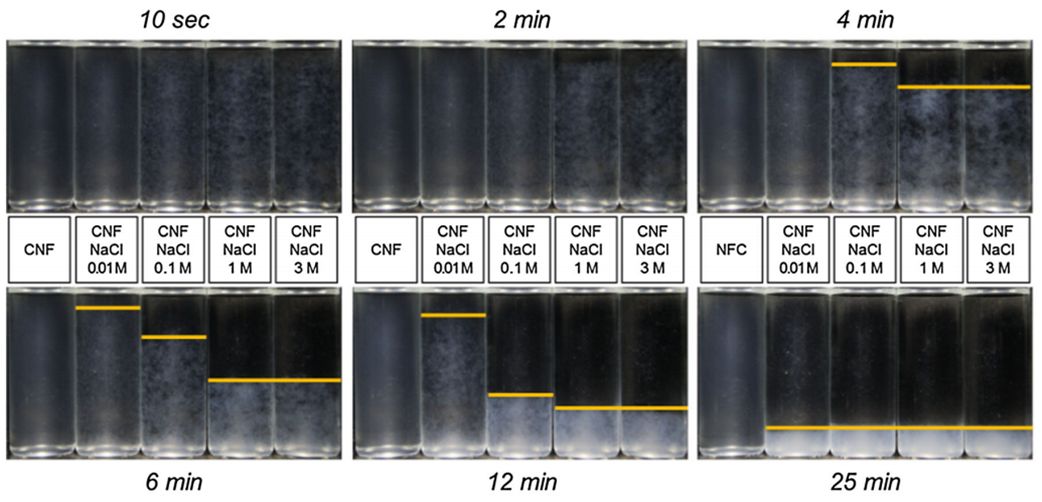

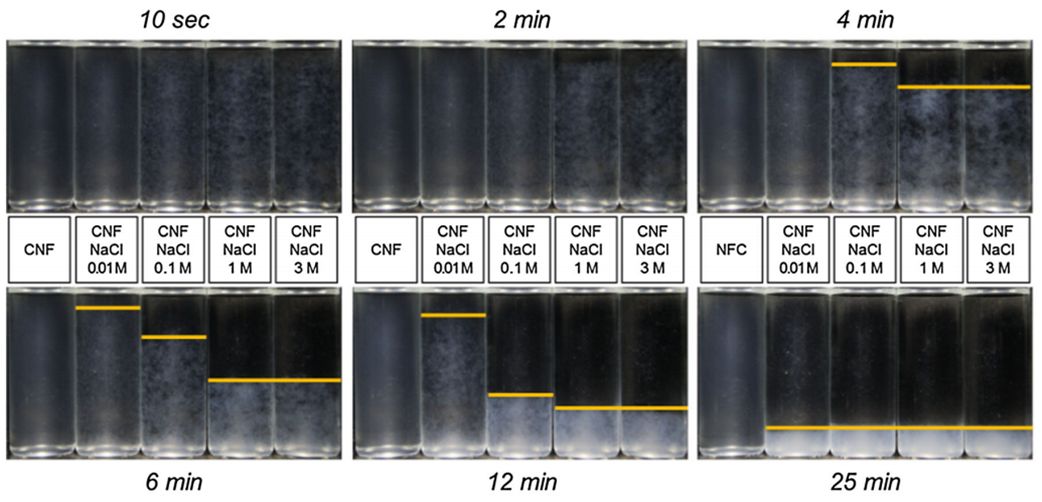

CNF suspension+CaCl2

The photos of CNF suspension with CaCl2 added at different moments are shown in the figure above. It can be seen from the figure that the precipitation process of CNF suspension appears irregular with the increase of CaCl2 concentration. It can be seen from the photos at 4-8min that the precipitation rate is the fastest when the concentration of CaCl2 is 0.1M. As the concentration of CaCl2 continues to increase, the precipitation rate decreases instead. It can be seen from the photo at 25 min that the concentration of CaCl2 causes the nanocellulose to form a different network structure.

2. The influence of salt on microrheological properties

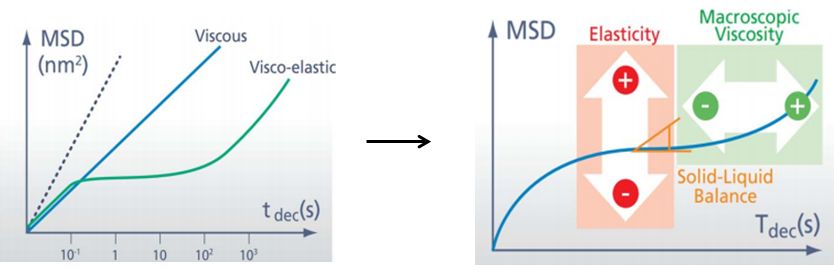

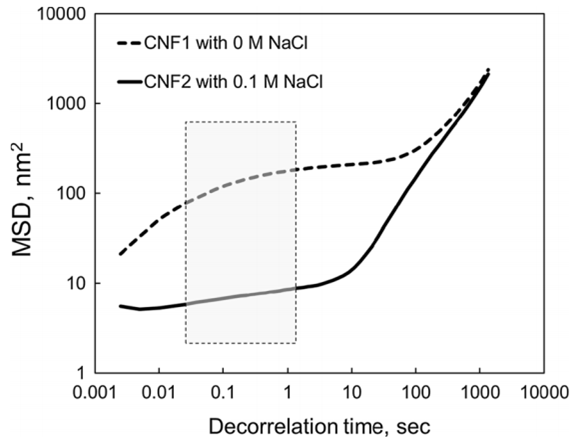

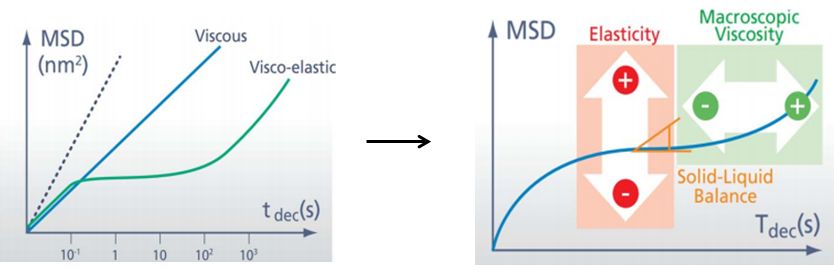

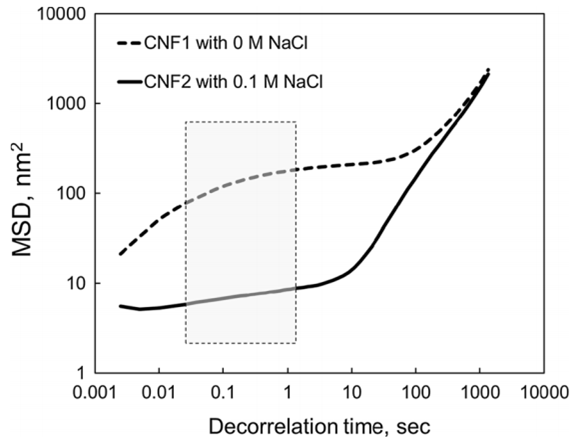

MSD curve of nanocellulose suspension (rheolaser data)

The MSD curve of nanocellulose suspension before and after adding NaCl is shown in the figure above. The MSD root mean square displacement represents the moving area of the particle. Before adding NaCl, the MSD curve platform area is at a higher position (data in the box), which indicates that the particle moving area in the network is larger; after adding NaCl, the MSD curve platform area is significantly reduced, indicating that the particle moving area in the network Smaller. This means that the addition of salt reduces the network pore size of nanocellulose.

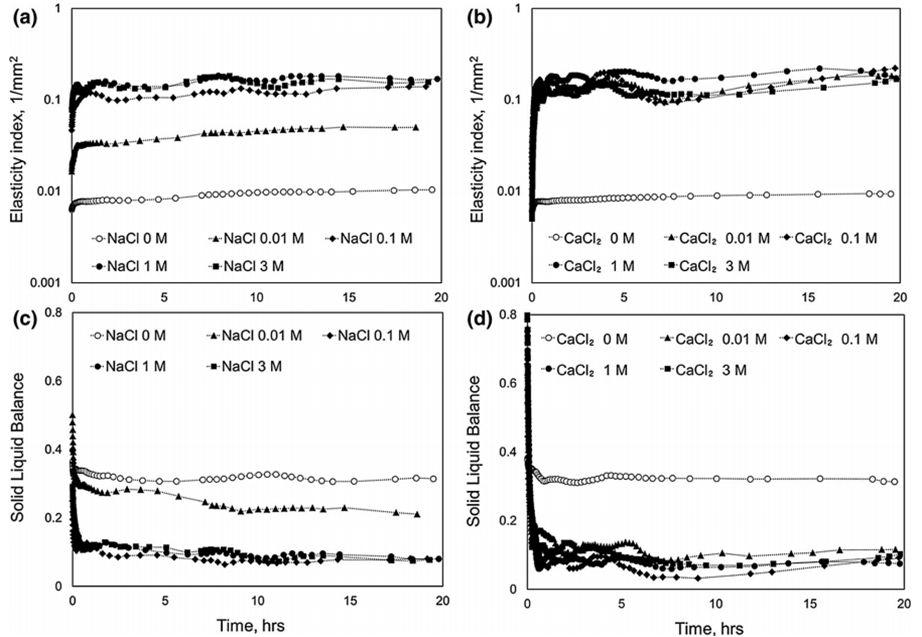

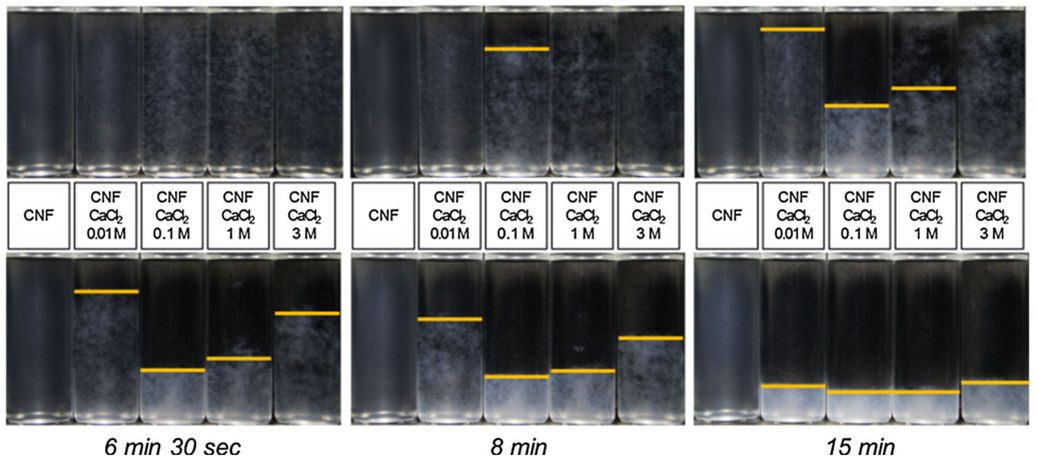

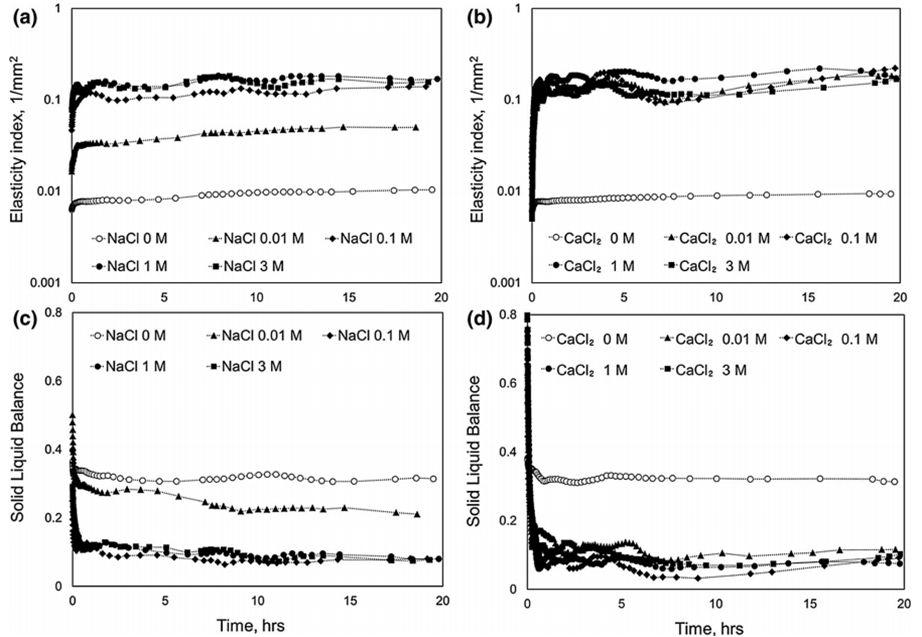

EI&SLB curve of nanocellulose suspension (rheolaser data)

The change process of elasticity factor (EI) and solid-liquid equilibrium point (SLB) of nanocellulose suspension after adding salt is shown in the figure above. The EI elasticity factor represents the elastic strength of the system where the particle is located, and the SLB solid-liquid equilibrium point represents the nature of the system where the particle is located (SLB→0, solid, SLB→1, liquid, SLB=0.5, solid-liquid balance). After the addition of NaCl, EI increased rapidly, and as the concentration of NaCl increased, the EI gradually increased. At the same time, the SLB decreased rapidly, and as the concentration of NaCl increased, the SLB gradually decreased. After adding CaCl2, EI increased rapidly and SLB decreased, and the concentration of CaCl2 had little effect on the final EI value and SLB value. This can indicate that as long as a small amount of CaCl2 exists, the network structure of nanocellulose can be changed to the final state. As the concentration of CaCl2 continues to increase, the zeta potential of the cellulose suspension changes significantly.

3. The effect of salt on dehydration performance

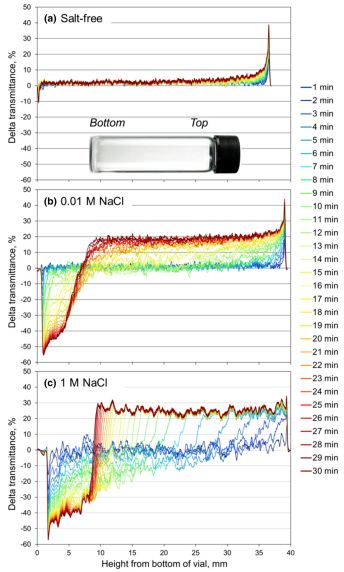

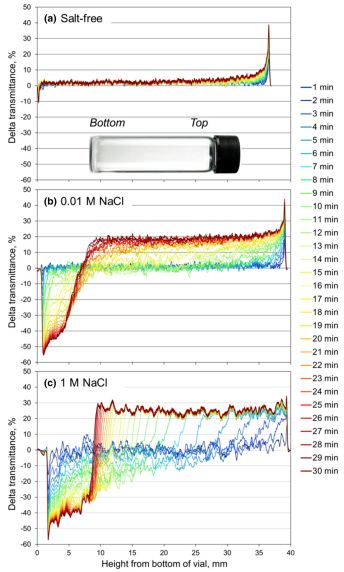

The influence of salt concentration on dehydration process (turbiscan data)

The scanning curves of the nanocellulose suspension without salt are basically overlapped, indicating that the suspension is basically stable without salt. After adding 0.01M NaCl, the light transmission at the bottom decreased and the light transmission at the top increased, indicating that the nanocellulose began to precipitate. After 1M NaCl was added, the interval between scan lines increased significantly, indicating that the precipitation rate increased.

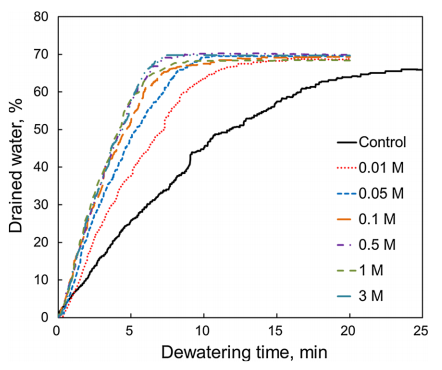

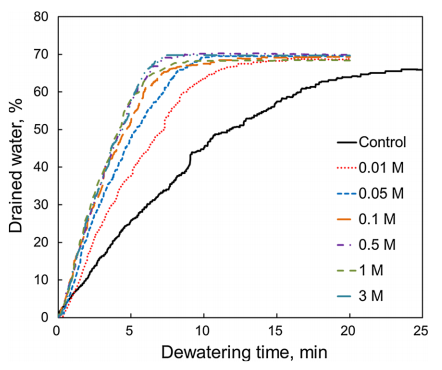

The influence of salt concentration on dehydration process (turbiscan data)

Using Turbisoft to obtain the change process of sample dehydration over time, it can be found that the influence of NaCl concentration on dehydration rate increases regularly.

in conclusion

Multi-speckle diffusion spectroscopy (Rheolaser) is a new test method, suitable for studying the viscoelastic properties of structurally fragile materials, and very suitable for in-situ monitoring of the network structure strength of the sample‘s sol-gel change process. With static multiple light scattering (Turbiscan), the instability process and particle size change process of the suspension can be accurately characterized.

Quoted from DOI10.1007/s10570-015-0784-y

This information is sourced from the Internet for academic exchange only. If there is any infringement, please contact us to delete it immediately.