Vacuum coating refers to the deposition of a metal or non-metal on the surface of the material in the form of a vapor in a vacuum environment to form a dense film. The quality of the coating is critical to the functional formation of semiconductor devices.

Technology application

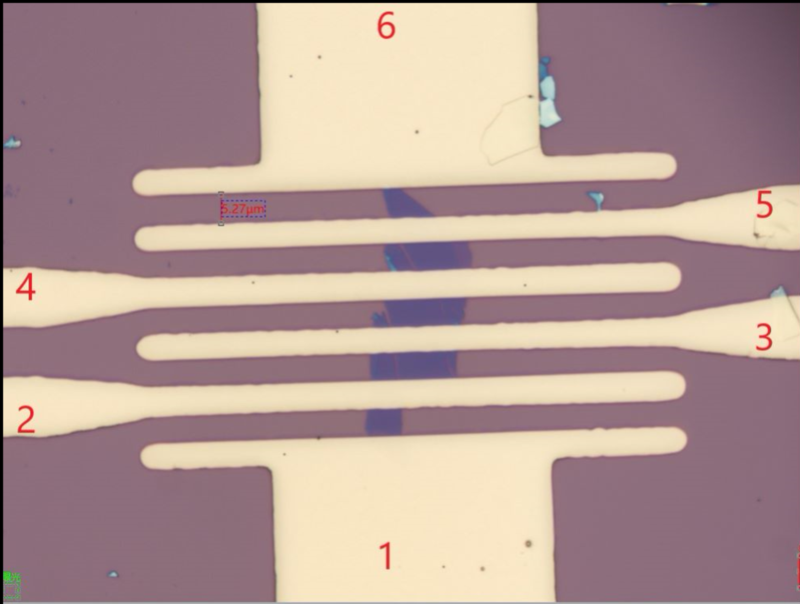

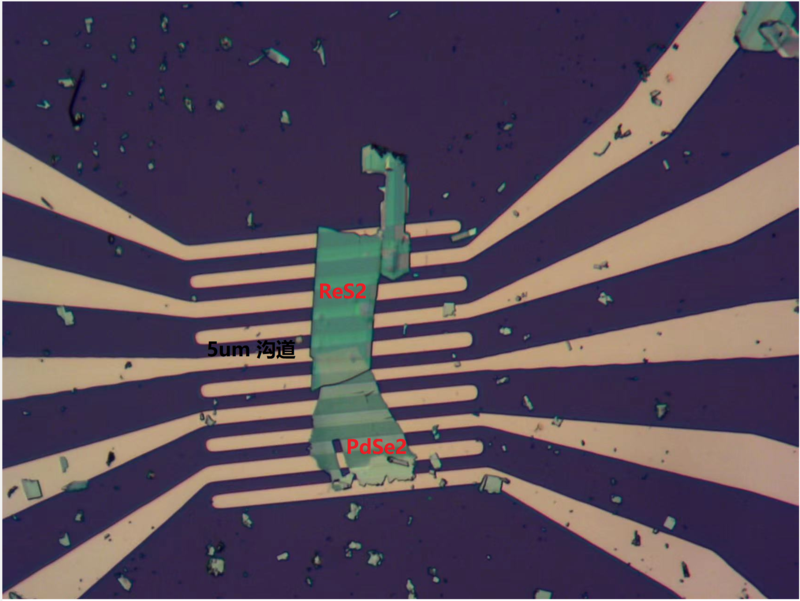

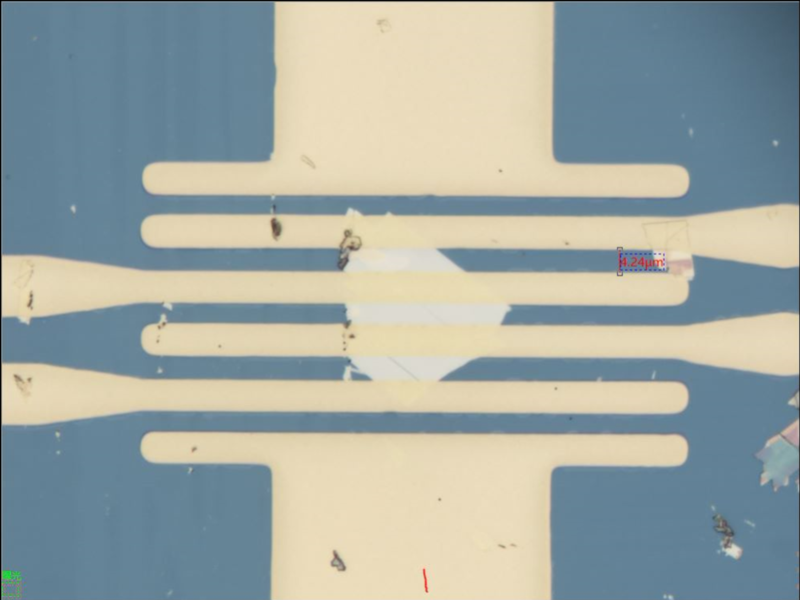

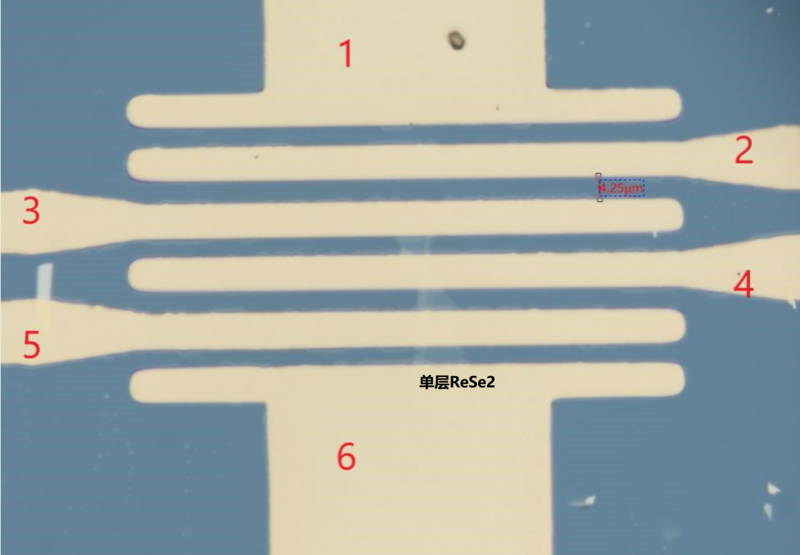

Coating technology is mainly used in the manufacturing process of micro-nano semiconductor devices. Metal and ITO materials are mainly used in the preparation of electrodes, and other non-metallic materials are mainly used in the preparation of insulating dielectric layers and sacrificial mask layers.

Process capability

Master coating technology:

Electron beam evaporation Magnetron sputtering LPCVD PECVD ALD

Coating material:

Metal: Ti, Al, Ni, Au, Ag, Cr, Pt, Cu, TiW90, Pd, Zn, Mo, W, Ta, Nb, etc. Non-metal: Si, SiO2, SiNx, Al2O3, HFO2, MgF2, ITO, Ta2O5, etc.

Coated substrate:

Silicon wafer, quartz glass wafer, sapphire wafer, PET, Pi, etc.

Our advantage

Master a variety of coating technologies and a wide range of coating materials Coating thickness range: 5nm-2000nm Base size 6 inches downward compatible The uniformity of the coating is good, and the coating is dense.

|

Warm tip: the products supplied by Beijing Beike Xincai Technology Co., Ltd. are only used for scientific research, not for human body |