[meaning]

In many surgeries, surgical nets need to be firmly fixed in the target area to strengthen tissues, support organs or repair wounds. Common methods of joining include sutures, staples and screws, but they can damage tissue and prolong the operation time. Adhesion is considered to be a promising alternative for the attachment of surgical mesh to tissue, but the existing adhesion methods are too weak for most applications. Recently, Professor Lu Tongqing of Xi an Jiao Tong University and academician Suo Zhigang of Harvard University developed a composite material of hydrogel and surgical net, which can be adhered to the tissue firmly and stably. The team demonstrated the application of hydrogel mesh composite in wound closure, especially under high pressure or high tension. The related papers were published in proceedings of the National Academy of Sciences of the United States of America under the title of hydrogel – mesh composite for wond closure.

[Abstract]

Through developing the material family called hydrogel network composite material (HMC), the team can significantly broaden the function of the surgical network. HMCS retain all the properties of surgical nets and add one: adhesion to tissues. The HMC network was constructed by immersing the surgical mesh with the precursor. After curing, the precursor formed a polymer network of hydrogel, which had macroscopic topological entanglement with the fiber of the surgical net. During surgery, HMC is pressed onto the tissue, and the polymer in the hydrogel cooperates with the tissue. To demonstrate this concept, the team used poly (N- isopropylacrylamide) (PNIPAAm) / chitosan hydrogel and polyethylene terephthalate (PET) surgical net. In the presence of biological coupling agent, chitosan forms covalent bond with tissue, and the adhesion energy is more than 100 J · m-2. Under temperature, PNIPAAm becomes hydrophobic, so the hydrogel will not expand and adhere to stable. Compared with suturing surgical mesh, HMC distributes the force over a large area. In vitro experiments were conducted to study the application of HMC in wound closure, especially in tissues under high mechanical stress. The performance of HMCS in dynamic tissue was further studied in sheep operation.

[picture and text analysis]

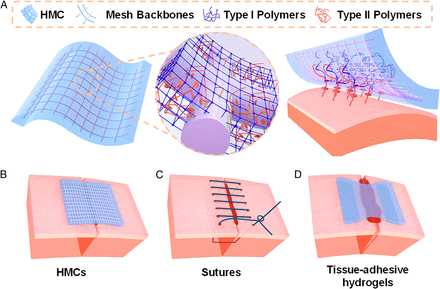

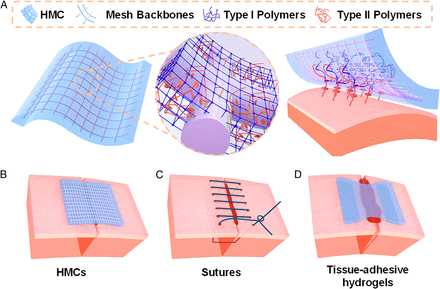

Hydrogels have two types of long polymer chains: I type polymers form covalent networks, and II polymers have functional groups attached to tissues (Fig. 1A). In order to peel HMC from tissue, the strong bond between type II polymer and tissue transfers the force to the covalent network of type I polymer.

Fig. 1 design and potential advantages of hydrogel network composite (HMC).

When HMC is used to close the wound, the surgical net acts as a skeleton to distribute the force under tension (Fig. 1b). In contrast, suture wound closure results in stress concentration in the tissue (Fig. 1c). Note also that the hydrogel itself is usually too weak to resist large tension (Fig. 1D). In addition, micropores in hydrogels and macropores in surgical mesh enable water and other small molecules to migrate in HMC. Therefore, HMC can be used as a scaffold and carrier for tissue regeneration for drug delivery. HMC will broaden the application of surgical mesh in tissue repair, sealing, hemostasis and wound closure, especially in tissues under high mechanical stress.

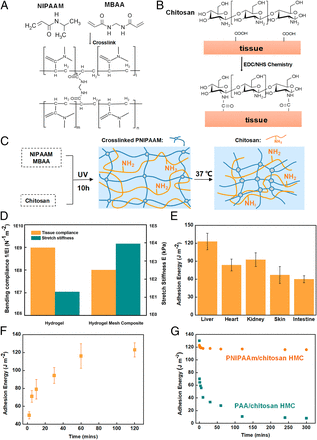

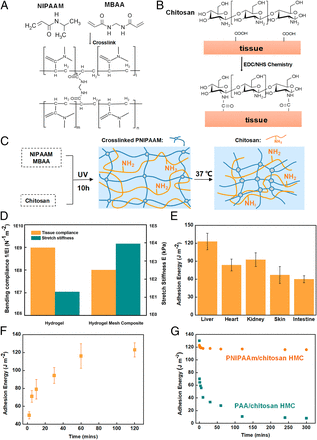

The team uses a specific material system to make HMCS. The mesh is woven with polyethylene terephthalate (PET) filament, and its aperture is about 50 μ m. In the glass mold. Chitosan polymer chains are mixed in the precursors of poly (N- isopropylacrylamide) (PNIPAAm) hydrogels. When the front body is poured into the mold, the solution will penetrate into the hole of the surgical mesh. In response to ultraviolet (UV) light, NIPAAm monomers polymerized into networks (Fig. 2a). PNIPAAm network forms intermolecular physical entanglement with chitosan chain and macro topological entanglement with PET filament. HMC integrates chitosan chain, PNIPAAm network and pet network. The composite is expected to have good biocompatibility.

Fig. 2 a hydrogel network composite material (HMC), in which the hydrogel has two types of long polymers: PNIPAAm (I) and chitosan (II).

The team used an aqueous solution of EDC / NHS coupling agent to adhere HMC to the tissue. The amino group (- NH2) on the chitosan chain forms a covalent bond with the carboxyl group (- COOH) on the tissue (Fig. 2b). When exposed to tissue at body temperature, the PNIPAAm network shrinks and resists expansion (Fig. 2C). The wound closure patch should have a large bending compliance to conform to the curved surface of the organ, and a large tensile stiffness to resist tissue tension. Hydrogel itself is easy to bend and stretch. In contrast, HMC has higher bending compliance and tensile stiffness (Fig. 2D).

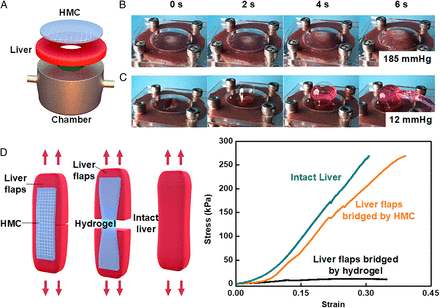

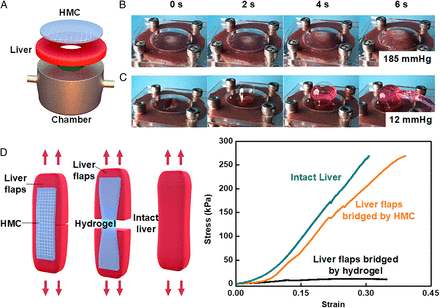

The team installed a pig liver with a 2 cm diameter hole into a chamber and attached a 500 micron thick HMC to the liver to cover the hole (Fig. 3a). When the syringe pumps fluid into the chamber, the HMC expands (Fig. 3b). In contrast, in the case of no mesh, by adhering the same thickness (500 μ M) when the PNIPAAm/ chitosan hydrogel is used to cover the hole, the burst pressure is 12 mmHg. The hydrogel ruptured but adhered well (Fig. 3C). Compared with the intact liver slices, the adherent samples have similar tensile strength, about 270 kPa. However, when two liver valves were separated by a piece of the same thickness (500 mm) μ M) when the pure water gel was bridged, the sample ruptured under the stress of ~20 kPa (Figure 3D).

Figure 3 mechanical test of HMC adhesion to injured tissue.

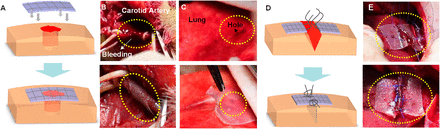

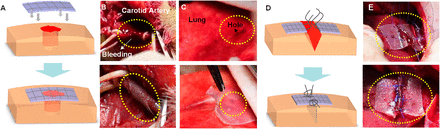

The team evaluated the hemostatic and immediate sealing effects of HMC on three types of tissue trauma. HMC can adhere to the injured tissue for hemostasis or repair (FIG. 4A). HMC conforms to the curved surface of artery and forms strong adhesion with tissue to stop bleeding (Fig. 4b). HMC has strong adhesion to the lung and is difficult to separate with forceps (Fig. 4C).

Fig. 4 Application of HMC in sheep operation.

The team also demonstrated a procedure called lace adhesive wound closure. Suture several sutures in two pieces of HMC, glue the sutured HMC to the wound, and then pull the suture like a shoelace (Fig. 4D). As a demonstration, an incision of about 30 mm was made in the sheep liver, and sutured HMC was adhered along both sides of the incision. Before pulling the wire, the wound will bleed. After the suture was tightened and knotted, the wound stopped bleeding (Fig. 4e).

[summary]

This paper presents a design called HMC, which broadens the function of surgical mesh by adding an important feature: strong adhesion to tissue. HMC can be manufactured by various adhesion strategies and various hydrogel materials and surgical mesh. The team illustrated this concept by using a specific system of PNIPAAm / chitosan HMC, which can form a firm and anti swelling adhesion to various tissues under physiological conditions. The team demonstrated that the combination of strong adhesion and high tensile stiffness allows HMCS to seal the wound against blood pressure and bridge the incision under tissue tension. A shoelace adhesive procedure using HMC for wound closure is also proposed. HMC may open the door for clinical surgery innovation.

This information is from the Internet for academic exchange only. If there is any infringement, please contact us to delete it immediately