hotline:

17715390137

Tel/Wechat:

18101240246 (Technology)

0512-68565571

Email:mxenes@163.com (Sales Engineer)bkxc.bonnie@gmail.com

Scan the code to follow or search the official account on WeChat:

2D Materials Fronrier After paying attention,

click on the lower right corner to contact us,

Enter enterprise WeChat.

Professional Services Online

[Research Background]

[Graphic and text guide]

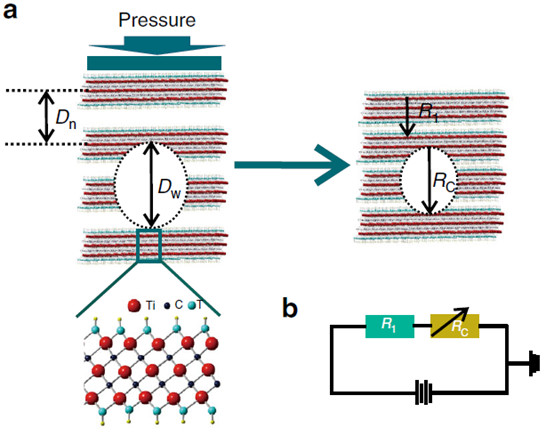

Figure 1. Microstructure of the working MXenes piezoresistive sensor: (a) Under the action of external force, the distance between two adjacent MXenes interlayers in the sensor decreases. Wide spacing (Dw) between two layers is more easily compressed, while narrow spacing (Dn) has a smaller compression ratio, (b) Equivalent circuit diagram of an MXenes-based piezoresistive sensor where the total resistance decreases with decreasing distance .

Fig. 2 Typical microstructure of MXenes and in situ dynamic process under external force. (a) TEM image of the cross section of the MXenes, the inner image shows the layered structure, (b) HRTEM image of the top view of the MXenes, the inner part is the corresponding diffraction pattern, showing good hexagonal features, (c) in the original In the dynamometer, a nanoindenter supported by a tapered tip was locally applied on the FIB-treated MXenes sample. (d)-(f) Under the action of external force, the wider distance in MXenes decreases rapidly from ~12 nm, via ~3 nm to ~0 nm at 7, 9, and 10 s, respectively, (g)-(i ) The narrower distances (4 intervals) marked with red lines are 5.23 nm, 4.98 nm and 4.81 nm, respectively, (j)-(l) were analyzed using digital photomicrography software. Measured from the initial state of g, the strain values of the h and i states are 4.78 and 8.03%, respectively. a, b is 4nm, c is 200nm, d-f is 40nm, g-i is 20nm.

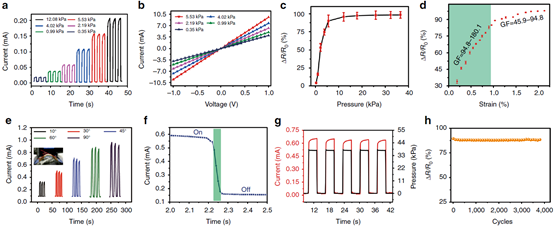

Figure 3. Pressure response of the MXenes sensor. (a) I-T curve at 13 kPa pressure. The current increases monotonically with increasing pressure, (b) the linear relationship of the IV curve indicates the ohmic contact between the MXenes and the interdigital electrodes, and (c) the ΔR/Roff increases sharply as a function of pressure for pressures less than 5 kPa, exceeding At 5 kPa, the growth rate slowed down. The SD of the data shown by the error bars is in the range of 1.44-8.21%, calculated by analyzing five sets of data at each pressure, (d) ΔR/Roff versus strain. GF is up to 180.1. The SD of the data represented by error bars is in the range of 0.26-1.78%, calculated by analyzing four sets of data at each strain value, (e) IT relationship at different bending angles, (f) an IT curve A partial zoom in, showing that its response time is less than 30 milliseconds. (g) When the load is added or removed, the output current and the external pressure are kept in good synchronization. (h) The resistance change rate ΔR/Roff maintains good stability.

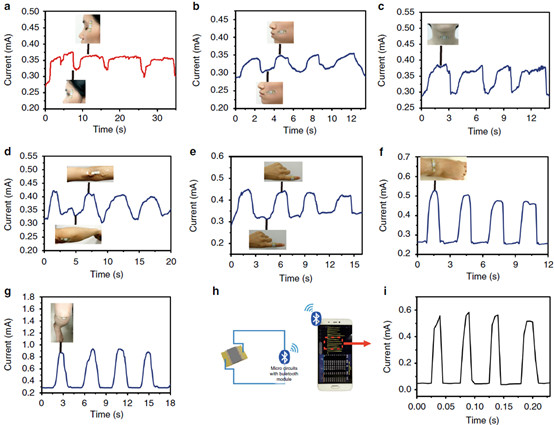

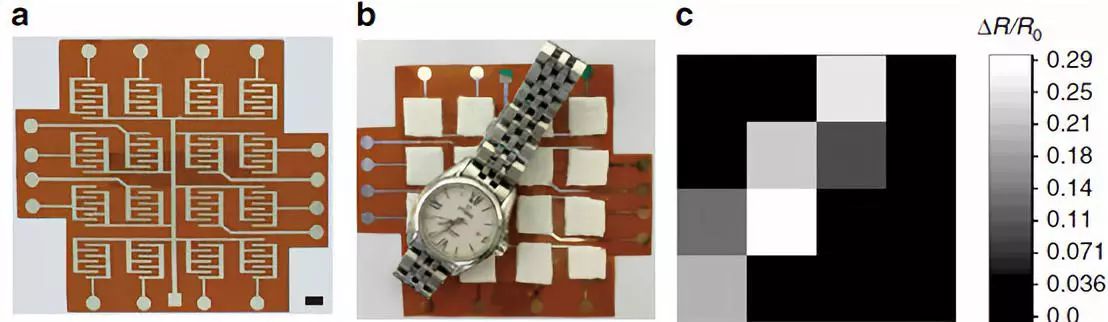

Figure 4. MXenes sensors are used to explore various human activities. The current changes of the sensor caused by small changes such as blinking (a), cheek bulging (b) and throat swallowing (c) are precisely recorded, (d)-(f) elbow joint (d), finger (e) and Changes in sensor current caused by flexion-extension motion of the ankle (f), (g) IT curve of knee joint flexion-extension, (h) The sensor is connected in series with a Bluetooth-implanted microcircuit to convert the current signal into a mobile phone signal, (i) ) The knee motion of the Bluetooth-implanted microcircuit is very similar in amplitude and shape to that of the Agilent device, but at a faster frequency.

| Reminder: Beijing Beike New Material Technology Co., Ltd. supplies products only for scientific research, not for humans |

| All rights reserved © 2019 beijing beike new material Technology Co., Ltd 京ICP备16054715-2号 |