【introduction】

Excessive emissions of carbon dioxide have caused a series of serious problems related to the environment and climate. Therefore, effective and innovative methods are needed to keep global net CO2 emissions within acceptable limits. Among the many possible solutions, electrochemical reduction of carbon dioxide (ECR) not only reduces carbon dioxide concentrations, but also converts them into fuels and household chemicals. However, the C = O chemical bond in CO2 is very thermodynamically stable, and a very high activation energy barrier is required to convert CO2 to the target product. In addition, during the electrochemical reduction of CO2, side reactions of hydrogen evolution (HER) will inevitably occur, which reduces its conversion efficiency. Based on the above problems, it is necessary to develop a CO2 electrocatalyst capable of suppressing HER side reactions and having high Faraday efficiency. In recent years, Cu, Au, Ag, Zn, Sn, and Bi have been extensively studied for the electrocatalysis of CO2 reduction. However, rich transition metals (such as Fe, Co, and Ni) have high HER activity and are also susceptible to CO poisoning, limiting their use in ECR. Recently, the design of non-noble metal monoatomic catalysts has shown excellent ECR activity. However, the synthesis of a single-atom catalyst usually requires multi-step processing of the precursor, which is complicated and costly. Exploring simple and low-cost methods to mass-produce monoatomic catalysts will remain an ongoing challenge.

[Achievement Profile]

Recently, Professor Sun Zhenyu of Beijing University of Chemical Technology, Professor Kang Peng of Tianjin University, and Professor Yousung Jung (co-corresponding author) of KAIST Korea have designed a novel and scalable strategy for the conversion of Ni particles into a stable individual Nickel atom. CNTs are coated with a polymer layer of resorcinol, melamine, and formaldehyde (RMF), followed by pyrolysis. During the pyrolysis process, Ni particles on the surface and inside the CNTs will thermally diffuse into the N-doped porous carbon matrix that encapsulates the CNTs, thereby achieving Ni–N coordination. The formation of Ni-N coordination sites greatly improved the reduction performance of electrochemical carbon dioxide, and the CO Faraday efficiency reached over 90%. The layered porous nitrogen-rich carbon shell layer facilitates the rapid transport of CO2, and CNT promotes electron conduction. The catalytic properties of Ni single atoms were explored by density functional theory (DFT) calculations, which predicted that the Ni @ N3 part might be the main active center for the electrocatalytic reduction of CO2 to CO. The related research achievement "Activation of Ni Particles into Single Ni–N Atoms for Efficient Electrochemical Reduction of CO2" was published on Advanced Energy Materials.

[Picture and text guide]

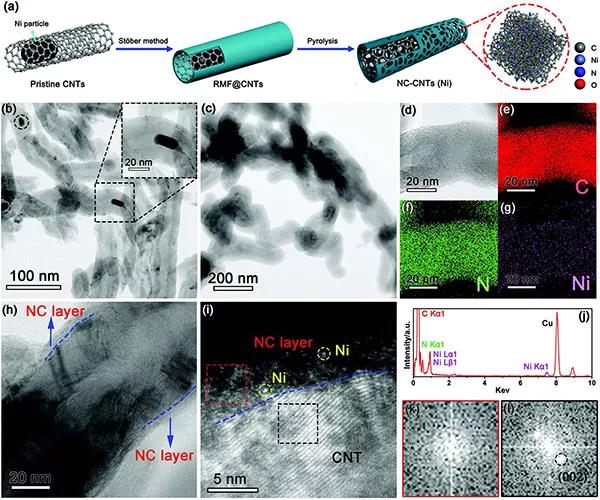

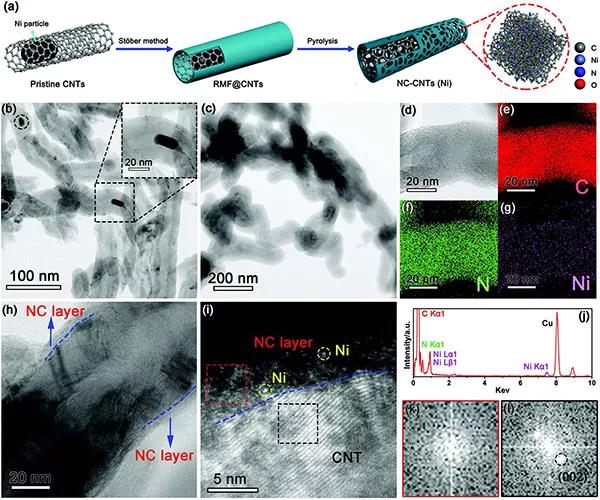

Figure 1. Schematic and TEM characterization of NC-CNT (Ni)

(A) Schematic diagram of the synthesis process of NC-CNT (Ni).

(B) TEM image of raw carbon nanotubes.

(C) TEM images of NC-CNTs (Ni).

(D) HAABF-STEM images of individual NC-CNTs (Ni) and corresponding EDX images.

(H) HAABF-STEM image, i) High magnification HAADF-STEM image, j) EDX spectrum of NC-CNT (Ni).

(K, l) FFT plots corresponding to the red and black dotted square areas shown in image i.

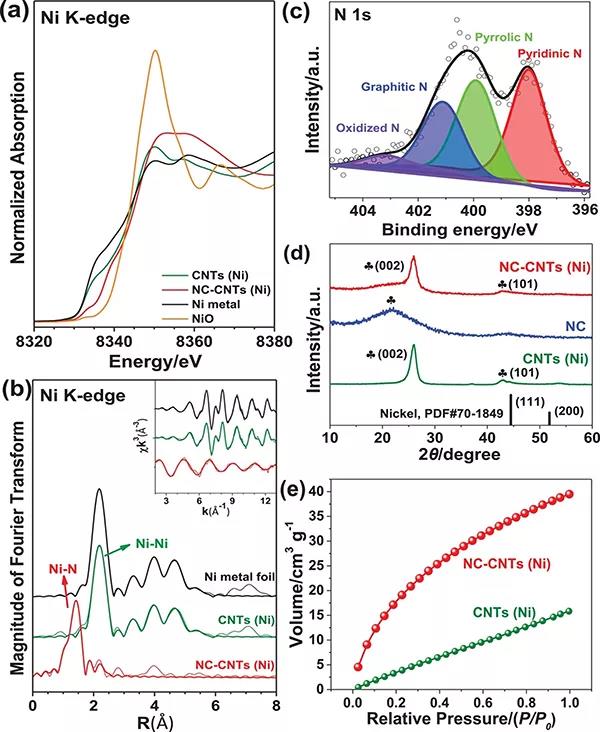

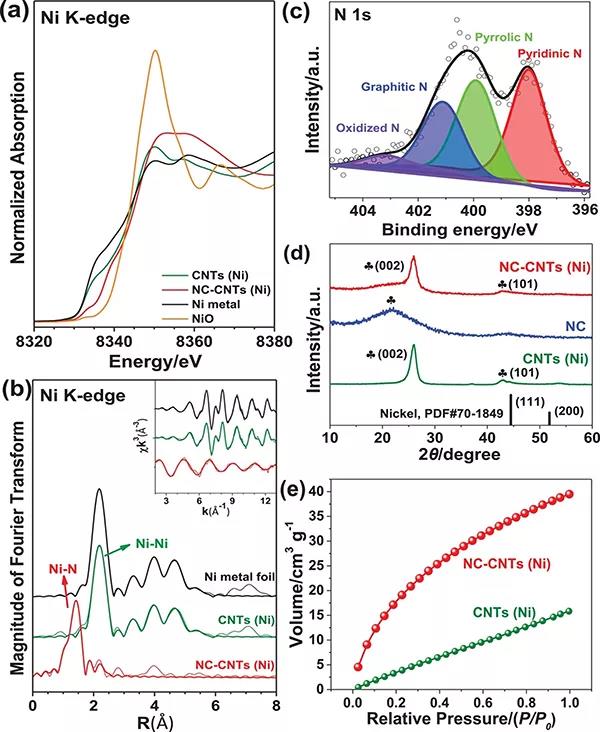

Figure 2. Other structural characterizations of NC-CNT (Ni)

(A) Ni K-edge XANES for NC-CNT (Ni), CNT (Ni), nickel metal and NiO.

(B) Compared with Ni metal foil, the EXAFS spectrum of the Ni K-side Fourier transform at NC-CNTs (Ni) and CNTs (Ni).

(C, d) N 1s XPS spectra and XRD patterns of CNT (Ni), NC and NC-CNT (Ni).

(E) CO2 adsorption isotherms of NC-CNTs (Ni) and CNTs (Ni).

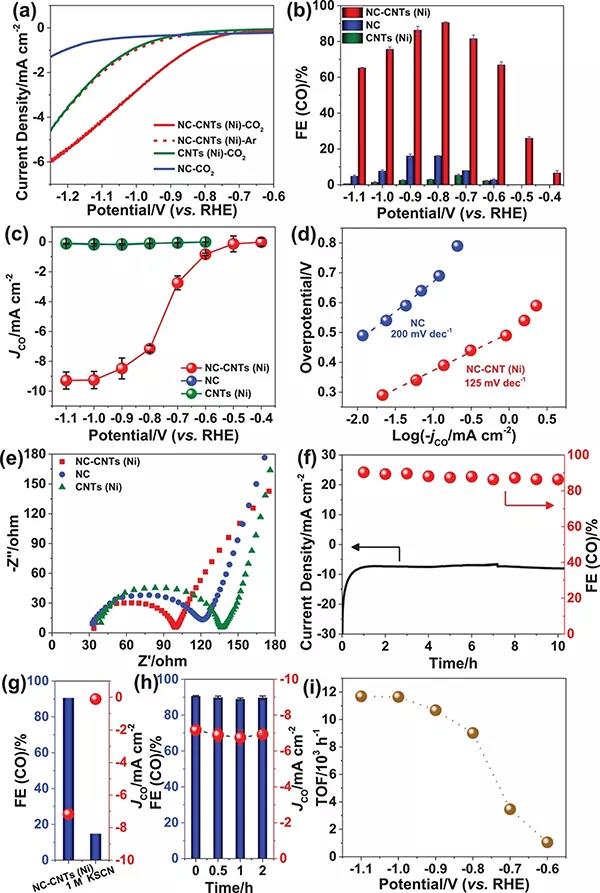

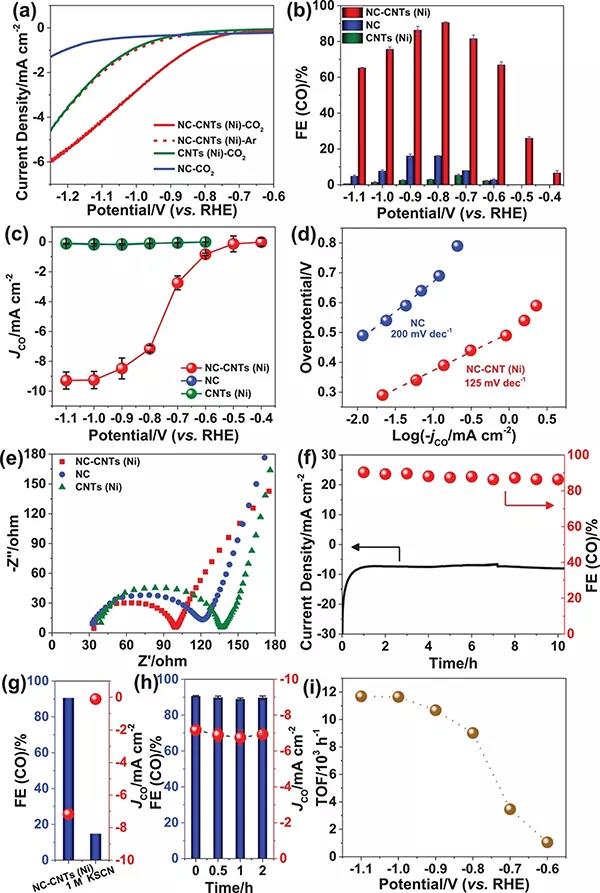

Figure 3. Electrochemical properties of NC-CNT (Ni)

(A) LSV curves of NC, CNT (Ni) and NC-CNT (Ni) at 0.1 M KHCO3.

(B) CO Faraday efficiency of NC, CNT (Ni) and NC-CNT (Ni).

(C) CO bias current density when various potentials are applied to NC, CNT (Ni) and NC-CNT (Ni).

(D) Tafel diagram of CO2 electrolytic reduction on NC and NC-CNTs (Ni).

(E) Impedance plots for three catalysts.

(F) Current density and CO FE of NC-CNTs (Ni) during long-term electrolysis at -0.8 V (vs RHE).

(G) CO FE and bias current density of NC-CNTs (Ni) before and after treatment in 1 M KSCN for 10 h.

(H) The CO FE and partial current density of NC-CNTs (Ni) treated at different times in 1 M H3PO4 were tested at -0.8 V (vs RHE).

(H) TOF of NC-CNTs (Ni) at different applied potentials.

Figure 4. Changes in the chemical state of Ni and its coordination environment

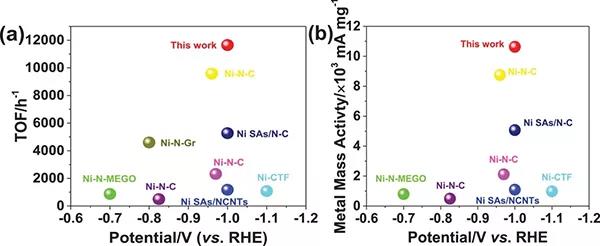

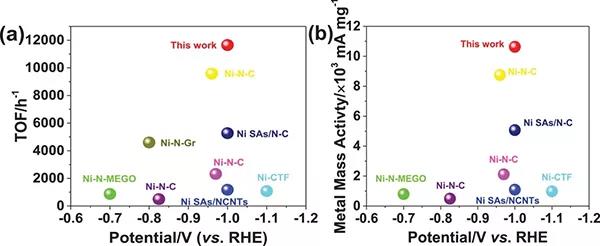

Figure 5. Comparison with other reported work

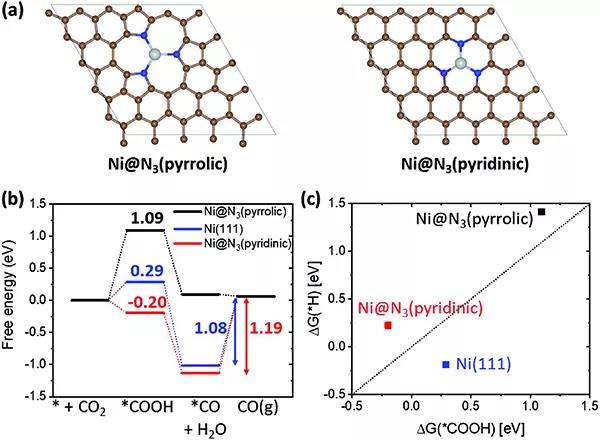

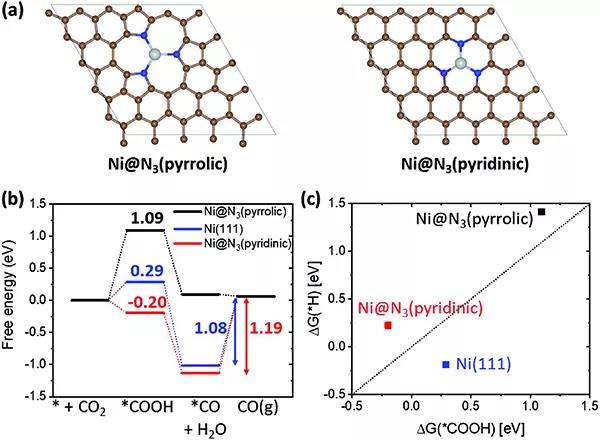

Figure 6. Catalytically active sites of NC-CNTs (Ni)

(A) Calculation models for Ni @ N3 (pyrrole) and Ni @ N3 (pyridine).

(B) Free energy diagram for reducing carbon dioxide to carbon monoxide.

(C) Comparison of ΔG (* H) and ΔG (* COOH).

【summary】

In summary, this article demonstrates a simple, novel, and scalable strategy to directly convert Ni particles embedded in CNTs into Ni single atoms through in-situ thermal diffusion. A single low-cost Ni atom in a porous N-doped carbon shell facilitates rapid mass transfer for CO2 electroreduction, and has excellent selectivity, stability, and high TOF. The discovery of highly active monoatomic catalysts provides unique insights into structural transformation and identification of active sites, which are important prerequisites for designing effective functional catalysts to reduce electrochemical CO2 to fuels and industrial chemicals.

Literature link:

"Activation of Ni Particles into Single Ni–N Atoms for Efficient Electrochemical Reduction of CO2" (Adv. Energy Mater., 2019, DOI: 10.1002 /aenm.201903068)

[Brief introduction of Sun Zhenyu and research group]

Sun Zhenyu is a professor and doctoral supervisor of Beijing University of Chemical Technology. He received his Ph.D. from the Institute of Chemistry, Chinese Academy of Sciences, and studied under the academician Han Buxing. He has been a post-doctoral fellow at Trinity College, Dublin, Ireland, Ruhr University, Bochum, Germany, and Oxford University, England, during which he received the German Humboldt Scholarship (for Experienced Researcher). 2015-present Professor at the School of Chemical Engineering, Beijing University of Chemical Technology. Currently, the research group is mainly engaged in research on the utilization of CO2 and N2 photocatalytic resources, and has published 115 papers in Nat. Nanotechnol. Among them, the first author and corresponding author published 75 papers in Chem, Angew. Chem. Int. Ed., Adv. Mater., Adv. Energy Mater., Nano Energy and other journals; Write 2 chapters in English books. 9 first / corresponding author papers were selected as ESI highly cited papers (including 1 hot paper). The total number of citations in the dissertation is> 8800, and the H index is 39. Authorized 4 Chinese invention patents. Selected as one of the top 1% highly cited scholars in RSC‘s 2018 magazine. Part-time editor of the Journal of Physical Chemistry.

This article was compiled and contributed by Microworld.

Source: WeChat public : Material man