Detailed consultation with customer service

Phase transition point

Determination of AC1, AC3, etc. of steel.

The critical point of phase transition.

It can be determined by thermal analysis, metallography, X-ray diffraction and electron microanalysis. For example, melting point, boiling point, isomorphic transformation point, eutectic point and peritectic point are all phase transition points.

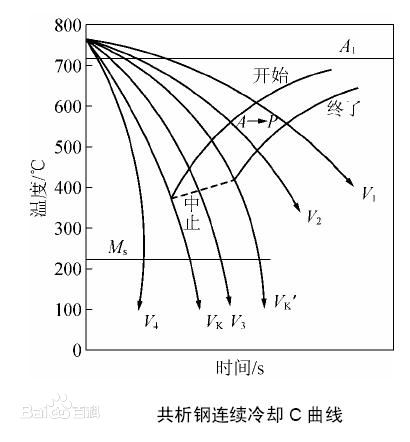

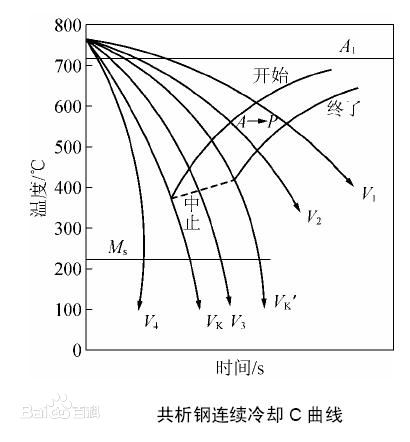

CCT curve

The continuous cooling transformation curve (CCT curve) of undercooled austenite reflects the transformation rule of undercooled austenite under the condition of continuous cooling, which is the basis for analyzing the structure and properties of the transformation products, and also an important reference for the formulation of heat treatment process.

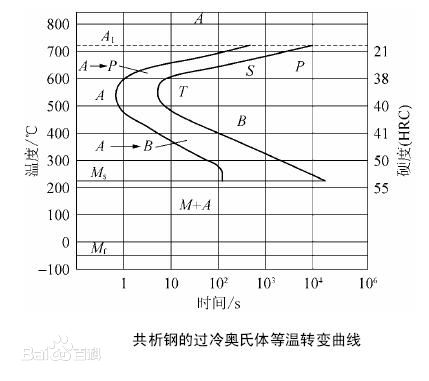

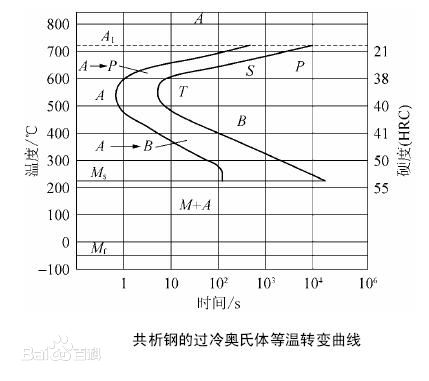

TTT curve

TTT curve: time, temperature, transformation curve of undercooled austenite

The TTT curve of undercooled austenite can comprehensively reflect the isothermal transformation process of undercooled austenite under different undercooling degrees: the time of beginning and end of transformation, the type of transformation products and the relationship between transformation amount and time, temperature, etc. Because its shape is usually like the English letter "C", it is commonly known as C curve, also known as TTT chart. The establishment of the isothermal transformation curve of undercooled austenite because the undercooled austenite not only has the change of structure and property, but also has the change of volume expansion and magnetism in the process of transformation, so the isothermal transformation curve of undercooled austenite can be measured by expansion method, magnetic method, metallographic hardness method, etc.

Coefficient of linear expansion

Also known as linear elasticity, it refers to the percentage change of material length per 1 ℃ change in temperature.

Dilatometer

Dilatometer German Baehr thermal analysis company, model dil805a

Equipment performance parameters:

Sample range: conductive solid sample

Sample size: φ 4 × 10 mm

Temperature range: room temperature ~ 1450 ℃;

Heating mode: induction heating

Environmental atmosphere: vacuum protection, vacuum degree 5 × 10-4mbar

Cooling medium: nitrogen

Cooling speed: max. 200 ℃ / S

Accuracy: 0.05 μ M / 0.05 ℃

Function and purpose of equipment:

It is used in the phase transformation experiment of metal materials. By measuring the length change of the sample during heating and cooling, the transformation temperature region of the corresponding structure is obtained.

1) The measurement of transformation point in the process of heating up, such as the measurement of AC1, AC3, etc;

2) The CCT curve was obtained by measuring the transformation point during continuous cooling;

3) TTT curve was obtained by measuring the transformation point in the process of constant temperature after rapid cooling;

4) The measurement of the coefficient of expansion in the heating and cooling process;

5) Heat treatment process and welding process simulation.

External services:

Static CCT, TTT test, AC1, AC3, linear expansion coefficient

Sample requirements: conductive solid

|

Warm tip: the products supplied by Beijing Beike Xincai Technology Co., Ltd. are only used for scientific research, not for human body |

| Item ID |

CAS |

ID |

Pack |

Parameter |

Stock |

Make up |

Price |

| BK2020011878-01 |

|

BK2020011878 |

|

相变点 |

100 |

|

$0 |

| BK2020011878-02 |

|

BK2020011878 |

|

CCT曲线 |

100 |

|

$0 |

| BK2020011878-03 |

|

BK2020011878 |

|

TTT曲线 |

100 |

|

$0 |

| BK2020011878-04 |

|

BK2020011878 |

|

线膨胀系数 |

100 |

|

$0 |

| BK2020011878-05 |

|

BK2020011878 |

|

膨胀仪 |

100 |

|

$0 |